Device and method for realizing lateral earth pressure in pile foundation model test

A lateral earth pressure and model test technology, which is applied in the test of foundation structure, foundation structure engineering, construction, etc., can solve the problems of large model size, the power capacity of the centrifuge cannot meet the requirements of the test, and the similar conditions are difficult. achieve the effect of avoiding mutual blocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

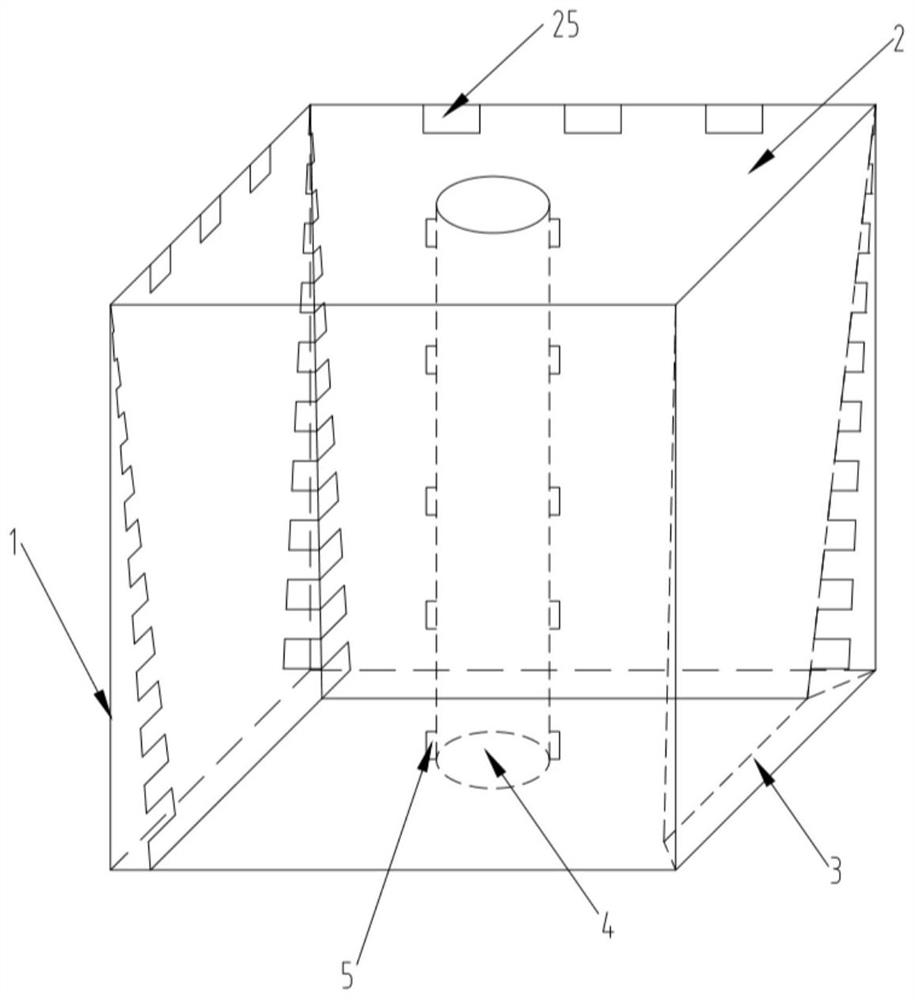

[0029] like Figure 1 to Figure 5 As shown, the device for realizing lateral earth pressure in the pile foundation model test described in this embodiment includes a model box 1, four lateral pressure transfer plates 2, four pressurized airbags 3 model piles 4, and a plurality of earth pressure sensor 5. Model piles 4 , four lateral pressure transfer plates 2 , four pressurized airbags 3 and multiple earth pressure sensors 5 are placed in the model box 1 , and soil fills the space in the model box 1 .

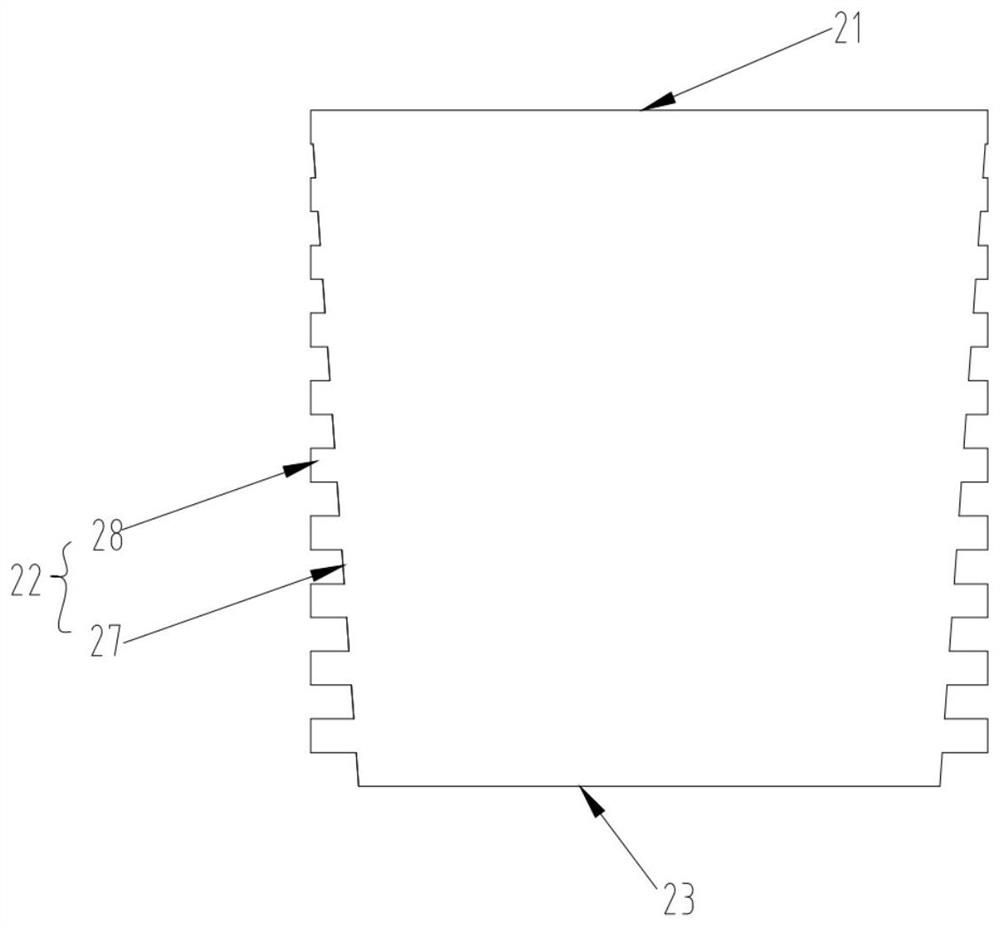

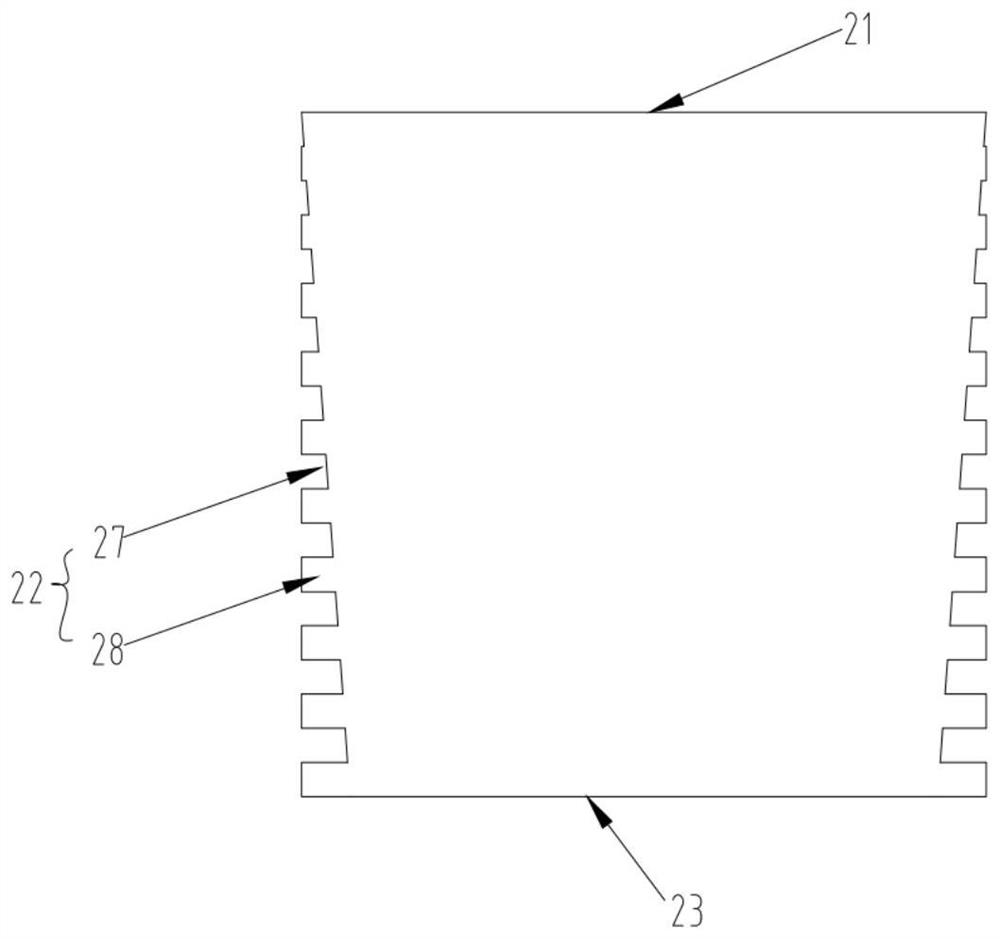

[0030] Among them, such as figure 2 and image 3 as shown, figure 2 and image 3 It is the lateral pressure transfer plate 2 that matches and engages with each other. The side pressure transmission plate 2 is a square plate body with four sides, namely a connecting side 21 , an occlusal side 22 , a swinging side 23 and another occlusal side 22 . On the same lateral pressure transmission plate 2, the connecting side 21 and the swinging side 23 form a pair of opposite sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com