Roller discharging machine

A technology of rollers and feeding machines, which is applied to the parts of grinding machine tools, machine tools and grinding machines suitable for grinding workpiece planes, etc. It can solve the problem of irregular blanking, low degree of automation, and affecting the efficient and orderly development of subsequent processes and other issues to achieve the effect of orderly development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the object, technical solution and effect of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

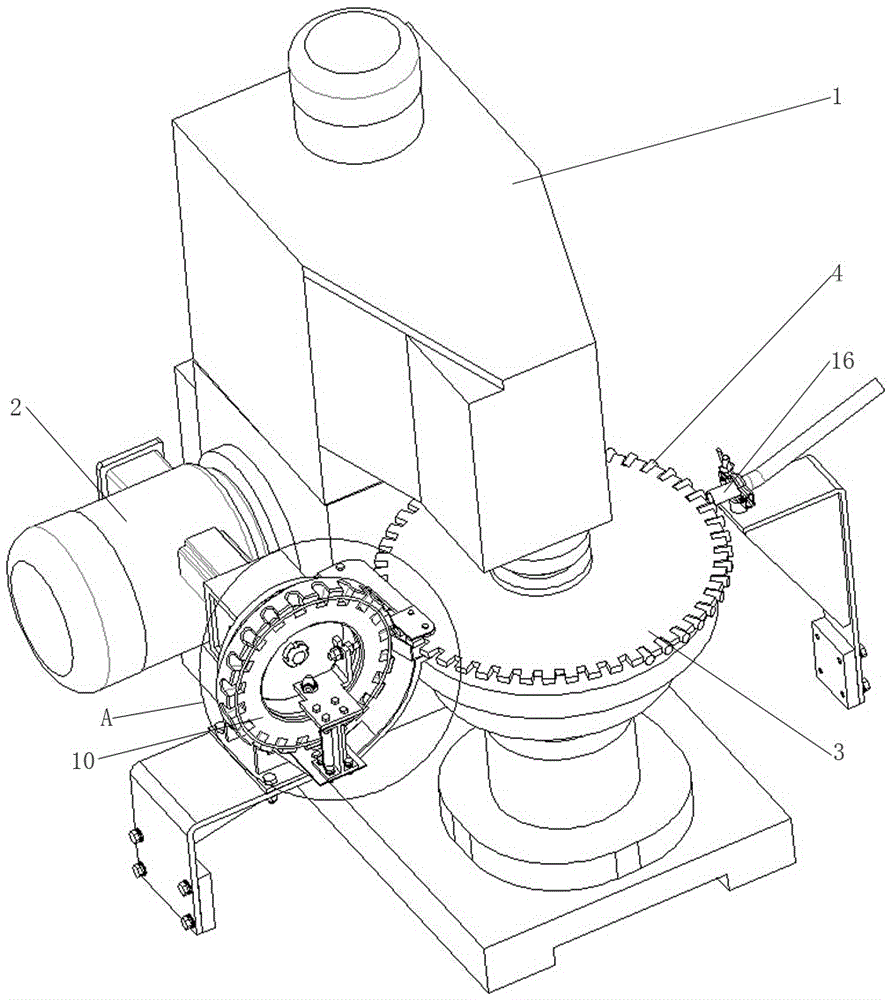

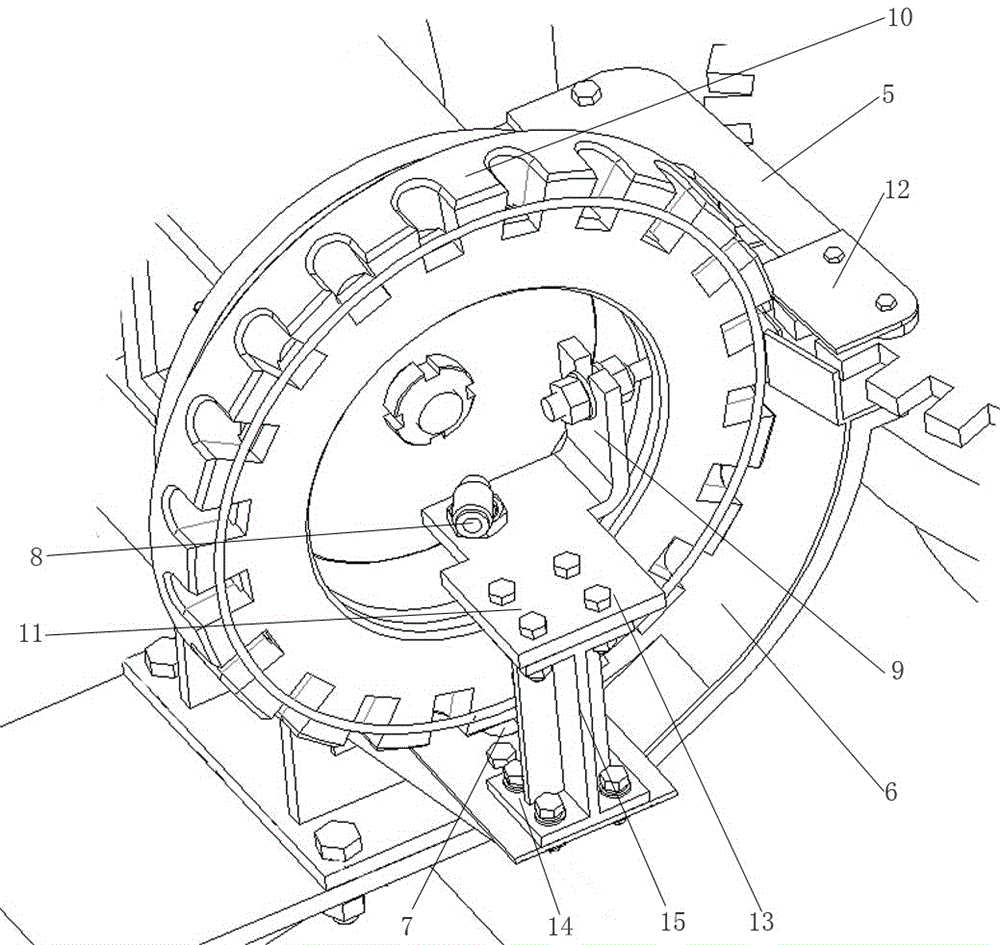

[0019] Such as figure 1 As shown, the roller blanking machine includes an end grinder 1, which is provided with a rotary toothed plate I3, and the circumference of the rotary toothed plate I3 is evenly distributed with card slots 4, and a rotary device is provided on the side of the rotary toothed plate I3. The device includes a motor 2, the output shaft of the motor 2 is connected to the rotary toothed plate II10 with a slot, the rotary toothed plate II10 is vertically arranged with the rotary toothed plate I3, the rotary device also includes a tapered roller transfer mechanism and a roller blowing mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com