Stirring device capable of mixing uniformly

A stirring device, a technology for uniform mixing, applied in mixers, shaking/oscillating/vibrating mixers, transportation and packaging, etc., can solve problems such as uneven mixing of mixers, achieve good mixing, ensure mixing quality, and be convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

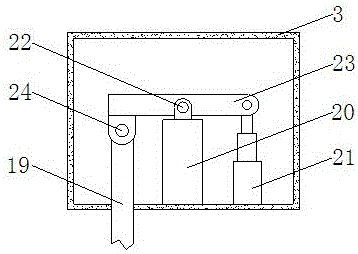

[0022] Example 1: Please refer to figure 2 , The bottom of the inner wall of the power box 3 is provided with a pillar 20 and an automatic telescopic rod 21 from left to right. When the automatic telescopic rod 21 is in operation, it can drive the rod 19 to continuously move up and down, which facilitates the continuous movement of the rod 19 to the mixing barrel. 9 Shake to better mix the stirring liquid, ensure the mixing quality of the stirring liquid, and improve the working efficiency of the stirring device. The top of the pillar 20 is fixedly connected with the second connecting block 22, and the second connecting block 22 is movable A movable plate 23 is connected. The top end of the automatic telescopic rod 21 is movably connected to the right side of the movable plate 23. The bottom left side of the movable plate 23 is fixedly connected with a third connecting block 24, which extends into the power box 3 The top end of the pull rod 19 is movably connected, the second c...

Embodiment 2

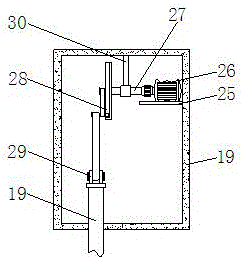

[0024] Example 2: Please refer to image 3 , The inner wall of the power box 3 is fixedly connected with a support plate 25, the support plate 25 is used to support the normal operation of the second motor 26, the top of the support plate 25 is fixedly installed with a second motor 26, the output shaft of the second motor 26 passes The coupling is fixedly connected with the second rotating shaft 27, and the end of the second rotating shaft 27 away from the second motor 26 is fixedly connected with a crank connecting rod 28. The function of the crank connecting rod 28 is to allow the pull rod 19 to continuously cycle up and down to ensure When the mixing device is working, the mixing barrel 9 can be shaken continuously, which facilitates the mixing of the mixing liquid. The top of the inner wall of the power box 3 is fixedly connected with a support frame 30, which supports the crank connecting rod 28. To ensure that the crank connecting rod 28 can operate normally, the bottom en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com