Hammering device

A crankshaft and frame technology, applied in the field of beating devices, can solve the problems of low production efficiency, continuous production and processing, and high processing costs, and achieve the effects of improving production efficiency, continuous processing and production, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

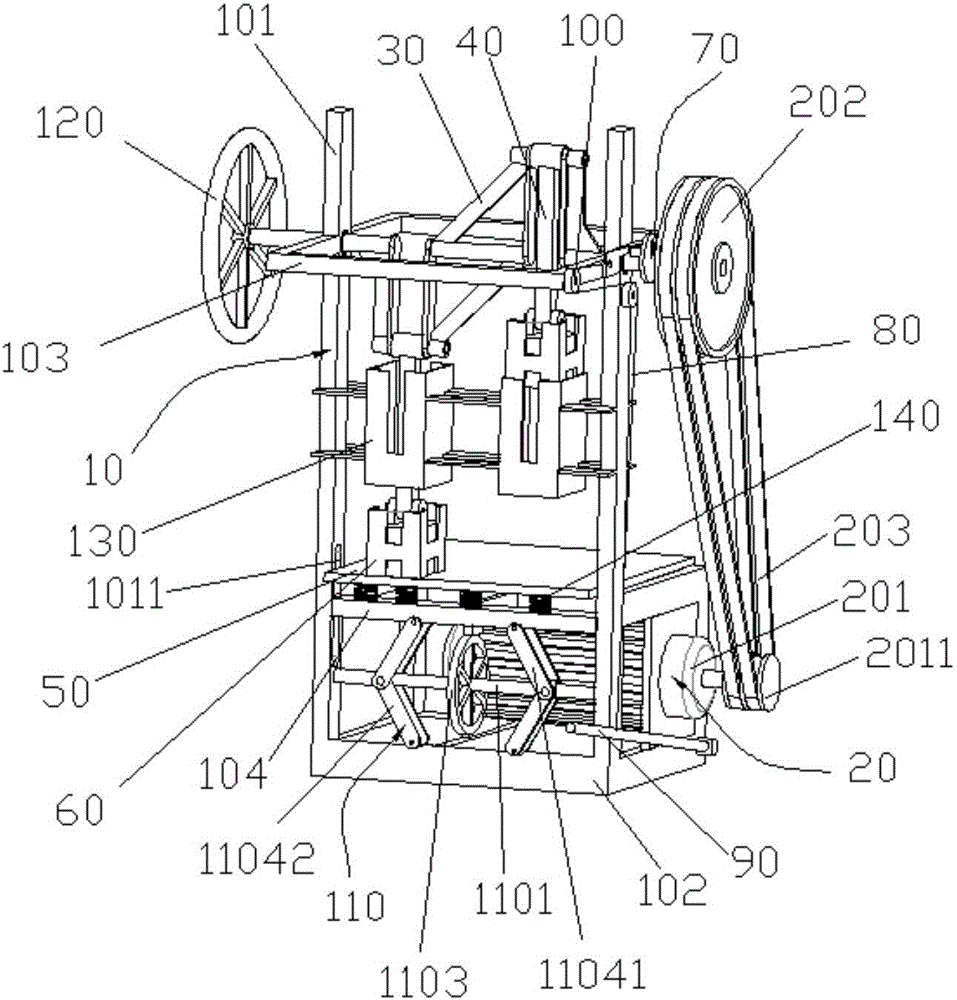

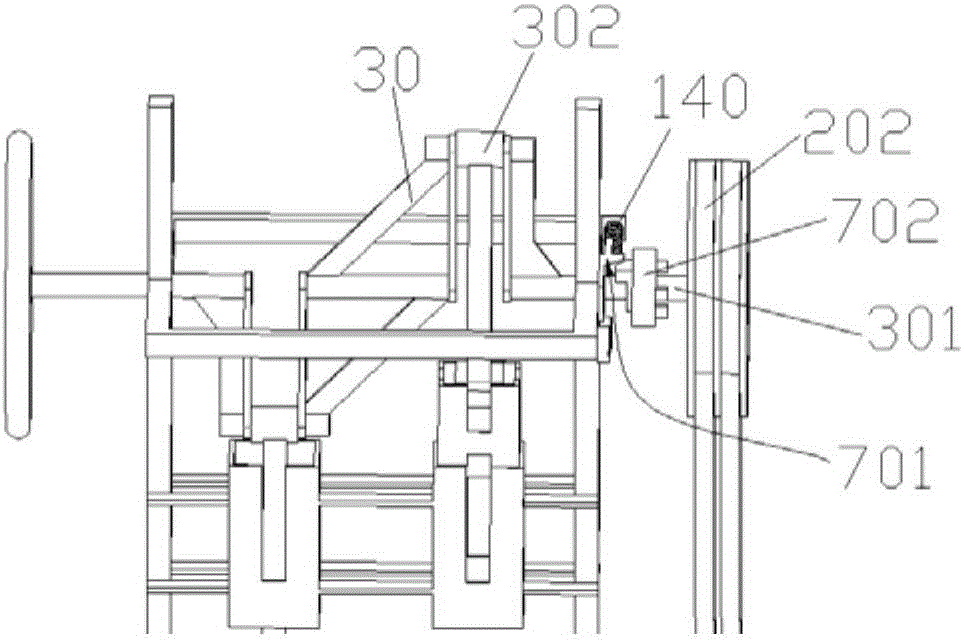

[0046] Such as figure 1 with figure 2 As shown, this embodiment provides a beating device, which includes a frame 10, a power drive unit 20, a crankshaft 30 pivotally connected to the frame 10, and a hammer head connecting rod whose one end is pivotally connected to the connecting rod journal 302 of the crankshaft 30 40 and an object carrier 50 fixed on the frame 10 in a horizontal direction. The other end of the hammerhead link 40 is pivotally connected with a hammer head 60 which is located above the object carrier 50.

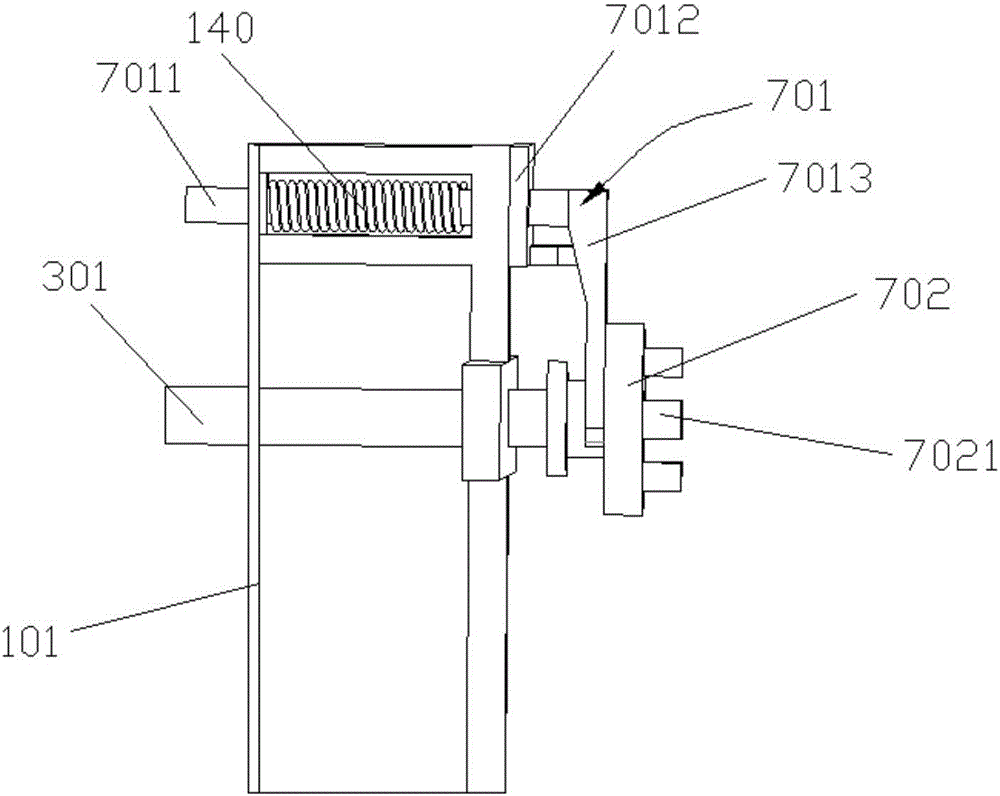

[0047] The power output end of the power drive unit 20 is connected with the main journal 301 of the crankshaft 30, and the main journal 301 of the crankshaft 30 is sleeved with a clutch 70 for controlling the synchronous movement of the crankshaft 30 and the power drive unit 20.

[0048] The beating device includes a frame 10 and a crankshaft 30 pivotally connected to the frame 10. When in use, the staff puts the marinated dried beef on the carrying plate 50. S...

Embodiment 2

[0076] In this embodiment, another beating device is also provided, which includes a frame 10, a conveying unit, a power drive unit 20, a crankshaft 30 pivotally connected to the frame 10, and one end pivotally connected to the connecting rod journal 302 of the crankshaft 30 The hammerhead link 40 and the loading board 50 fixed on the frame 10 in a horizontal direction, the hammerhead 60 is pivotally connected to the other end of the hammerhead link 40, and the hammerhead 60 is located above the loading board 50.

[0077] The power output end of the power drive unit 20 is connected with the main journal 301 of the crankshaft 30, and the main journal 301 of the crankshaft 30 is sleeved with a clutch 70 for controlling the synchronous movement of the crankshaft 30 and the power drive unit 20.

[0078] The conveying unit includes a conveying rack fixed on the frame 10, a transmission wheel pivotally connected to both ends of the conveying rack, a conveyor belt wrapped around the transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com