Vacuum Interrupter Pole for High Pressure Environment Applications

A vacuum interrupter and high-voltage environment technology, applied in the field of pole parts, to achieve the effect of tolerance compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

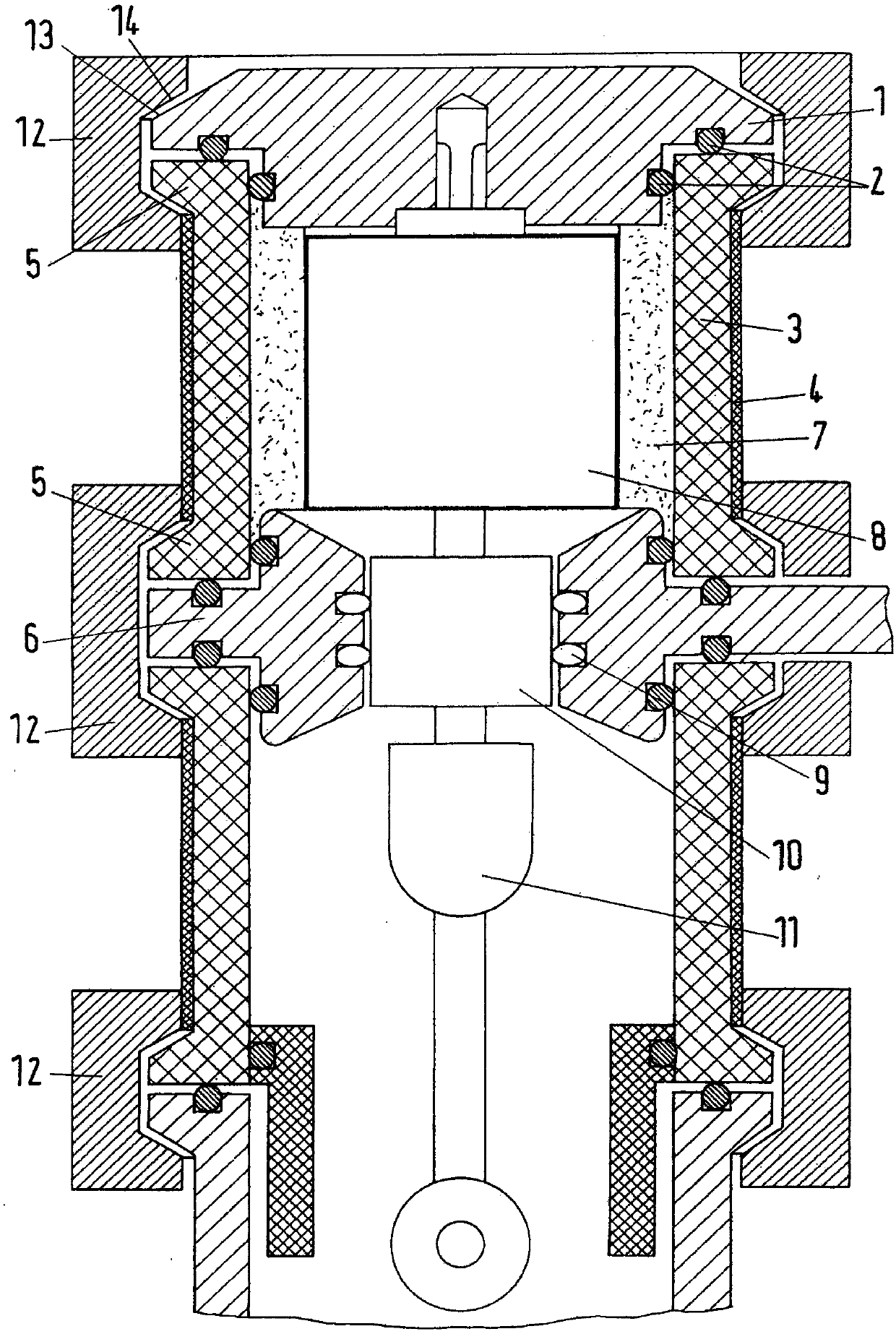

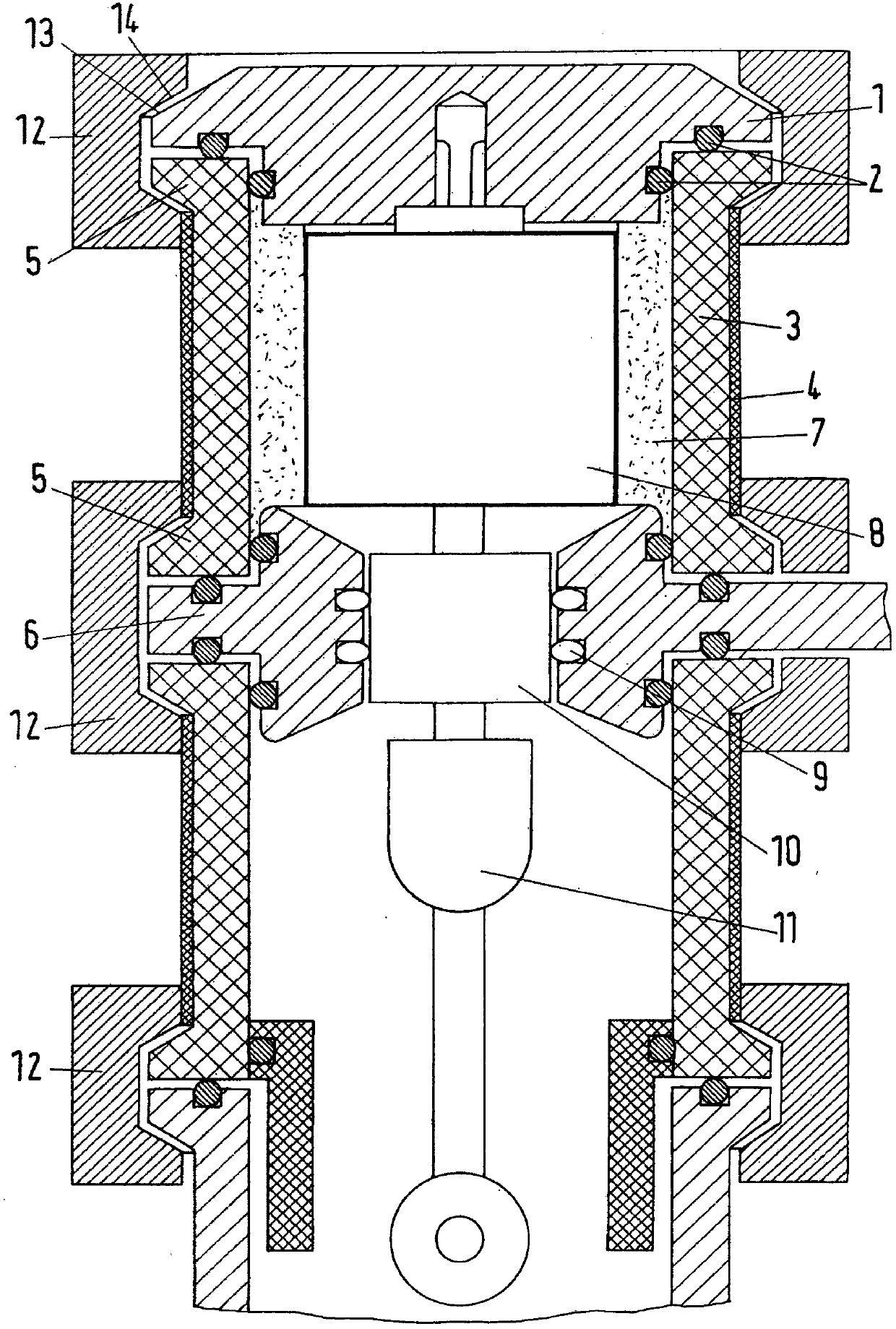

[0020] figure 1 Shown is an embedded pole part based on a ceramic housing as a high voltage part, wherein a vacuum interrupter 8 is mounted and inside the vacuum interrupter is provided with at least one moving contact and at least one stationary contact, and is provided with Terminated in an external contact rod or push rod 11 , which passes through the ceramic of the vacuum interrupter. In order to access the vacuum interrupter 8 from the outside, metal parts are mounted on both sides of the ceramic housing of the vacuum interrupter metal parts, and the connection from the ceramic housing to the place where the vacuum interrupter is connected is installed on the fixed contact side Department cover.

[0021] On the other side of the housing, a flange is provided at the ceramic part, which connects the movable side of the vacuum interrupter to the middle part of the flange by means of a sliding contact system 9 . Here, the electrical connection takes place and the connection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com