Motor bearing press mounting equipment

A technology of motor bearings and equipment, which is applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve problems such as laborious labor, difficulty in manual detection, and potential safety hazards, and achieve simple assembly operations, improve assembly efficiency, and ensure product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions in the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

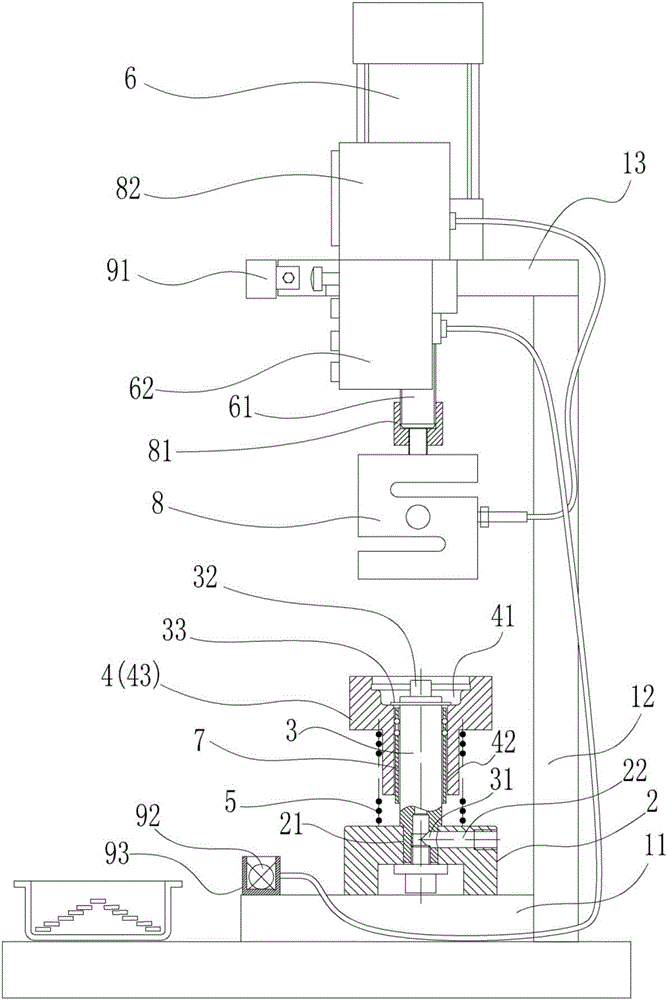

[0024] Such as figure 1 As shown, the present invention proposes a kind of motor bearing press-fitting equipment, comprising:

[0025] A support frame, the support frame is composed of a base plate 11, a support column 12 and a top plate 13 to form a 匚-shaped structure;

[0026] The fixed seat 2 fixed on the base plate 11, the upper end surface of the fixed seat 2 is provided with a vertical fixed hole 21, the side wall of the fixed seat 2 is provided with a horizontal first pin hole 22 and the first pin hole 22 is connected with the fixed Holes 21 communicate;

[0027] The bearing strut 3 installed above the fixed seat 2 through the fixing hole 21, the lower end of the bearing strut 3 is provided with a second pin hole 31 matching the first pin hole 22, and the top end of the bearing strut 3 is provided with a The boss str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com