A liquid metal assisted aluminum block direct hydrogen production device and its application

A liquid metal, hydrogen production device technology, applied in the direction of hydrogen production and other directions, can solve the problems of continuous hydrogen production and other problems, and achieve the effects of continuous and rapid hydrogen production, efficient production, and controllable hydrogen production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

[0036] Experimental example: the experiment of liquid metal assisted aluminum plate reacting with aqueous solution to generate hydrogen

[0037] The liquid metal is gallium-indium alloy (90% gallium, 10 indium), and the aluminum plate is 6061 aluminum plate. Use a spray gun to spray a layer of liquid metal on the surface of the aluminum plate, and recover the liquid metal with alcohol after a few seconds. Drop the aqueous solution (5% NaCl aqueous solution in the experiment) onto the corroded area of the aluminum plate, and it can be seen that a large number of small bubbles are generated, that is, H 2 , and the amount of hydrogen generated is significant, and the process is very stable. The amount of hydrogen produced can be regulated by corroding the surface area of the aluminum plate with the liquid metal. Since gallium indium alloy has a corrosive effect on aluminum, it can avoid the formation of a protective film on the surface of aluminum, thereby ensuring the conti...

Embodiment 1

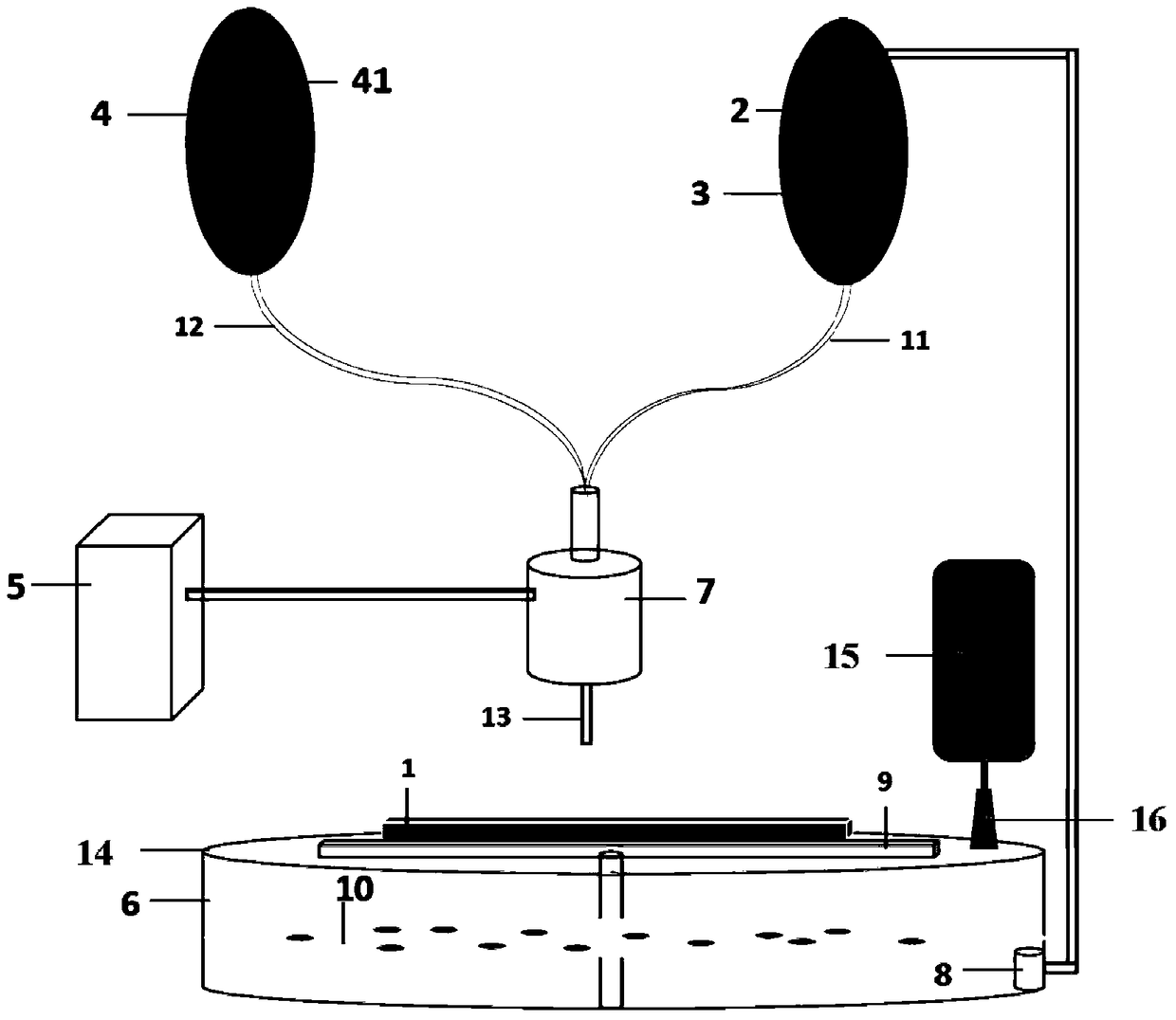

[0040] A liquid metal assisted direct hydrogen production device of aluminum blocks, comprising an aluminum plate 1, a liquid metal tank 2, an aqueous solution tank 4, a hydrogen gas collection tank 15, a waste liquid recovery tank 6, a rotary nozzle 7, and a lifting platform 9. The rotary nozzle 7 is connected to the aqueous solution tank 4 through the aqueous solution pipeline 12, and the liquid metal tank 2 through the liquid metal pipeline 11. An aluminum plate 1 is arranged below the rotary nozzle, and the aluminum plate 1 is placed on a lifting platform, which is located in the waste liquid recovery pool. The hydrogen collection tank 15 is connected to the waste liquid recovery tank 6 through a hydrogen collection pipeline 16 . The top of the waste liquid recovery pool 6 is provided with a waste liquid recovery pool airtight door 14. When the lifting platform 9 rises, the door is opened, and after the lifting platform 9 descends, the door is closed, so that the waste liqu...

Embodiment 2

[0050] The structure of the liquid metal assisted aluminum block direct hydrogen production device is the same as in Example 1, and the method for preparing hydrogen is as follows:

[0051] 1) Fill liquid metal 2 in the liquid metal tank 3, the liquid metal is a gallium indium tin alloy (68.5% gallium, 21.5% indium and 10% tin), and the aqueous solution tank 4 is NaCl with a mass concentration of 5% Aqueous solution 41;

[0052] 2) The pipeline connecting the rotating nozzle and the liquid metal tank is opened, the nozzle diameter of the spray gun is 0.5mm, and the pressure of the high-pressure gas tank is 0.3MPa. Place an aluminum block with a length, width, and height of 80mm×20mm×20mm on the lifting table, and the rotating nozzle sprays liquid metal on the aluminum plate, and stops spraying the liquid metal after 5 seconds, and the pipeline connecting the rotating nozzle and the aqueous solution tank 4 is opened, and spraying and flushing The liquid metal is washed away by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com