Synchronous lifting device and material conveying device

A technology of synchronous lifting and material, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of damaged life of related components, difficult accuracy requirements, complex action programs, etc., to improve service life and simple action programs. , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

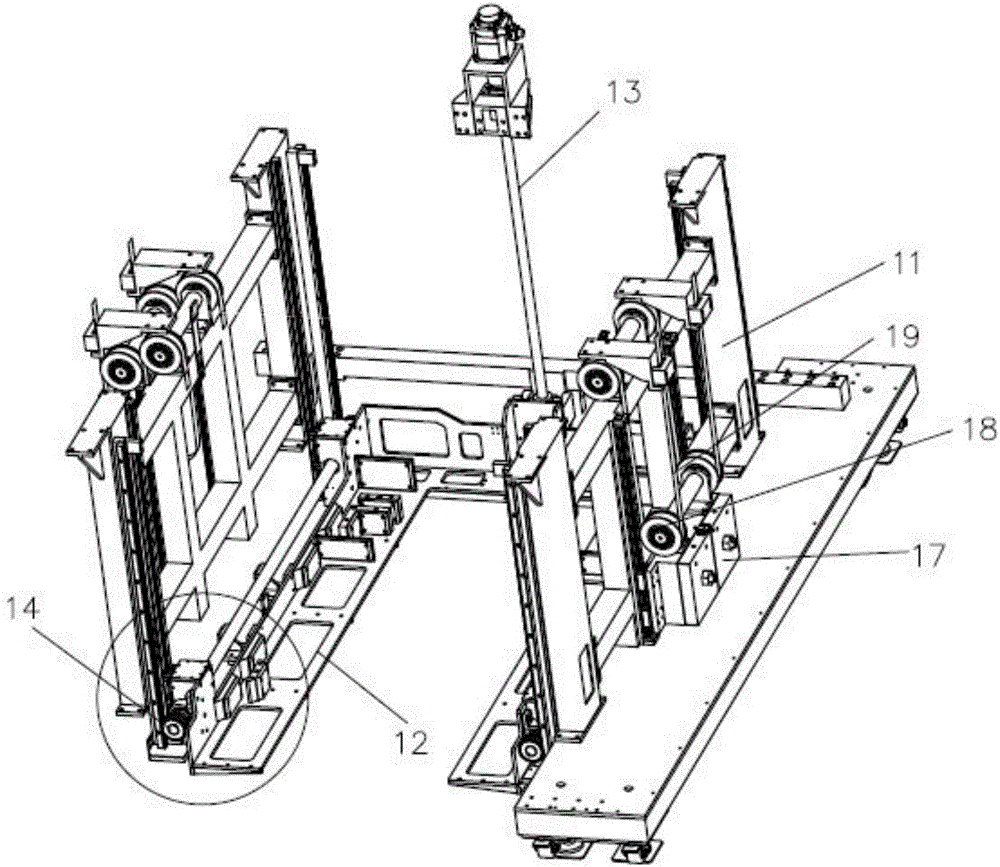

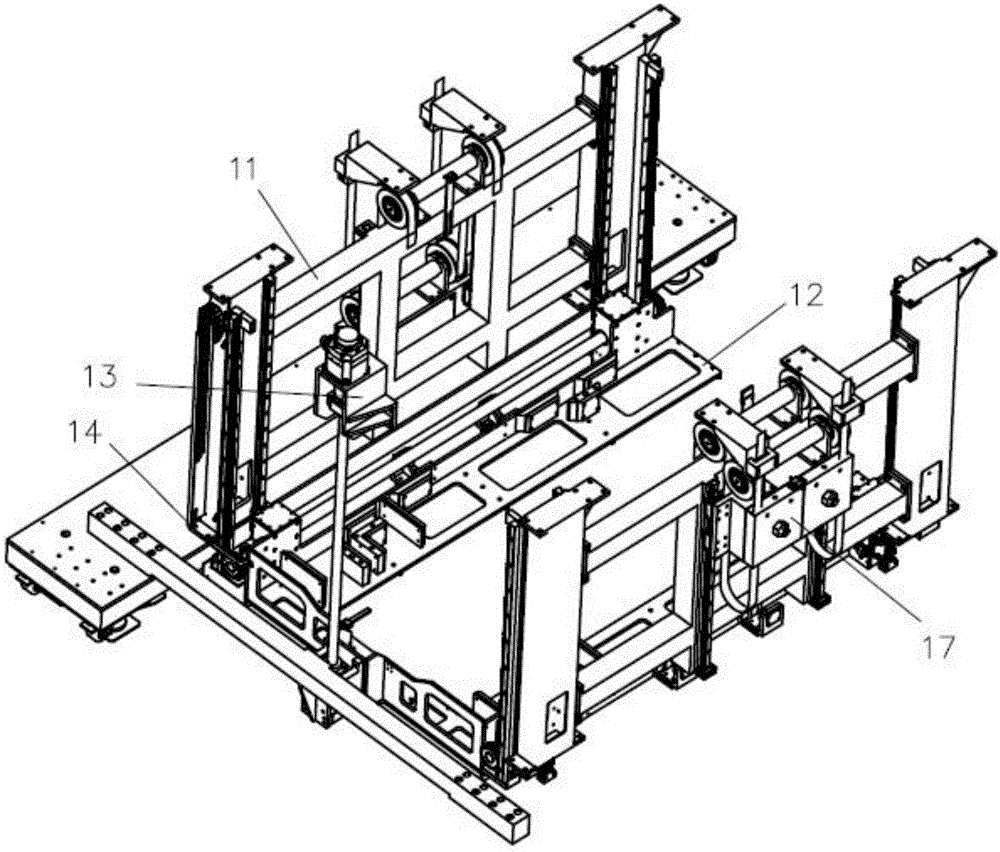

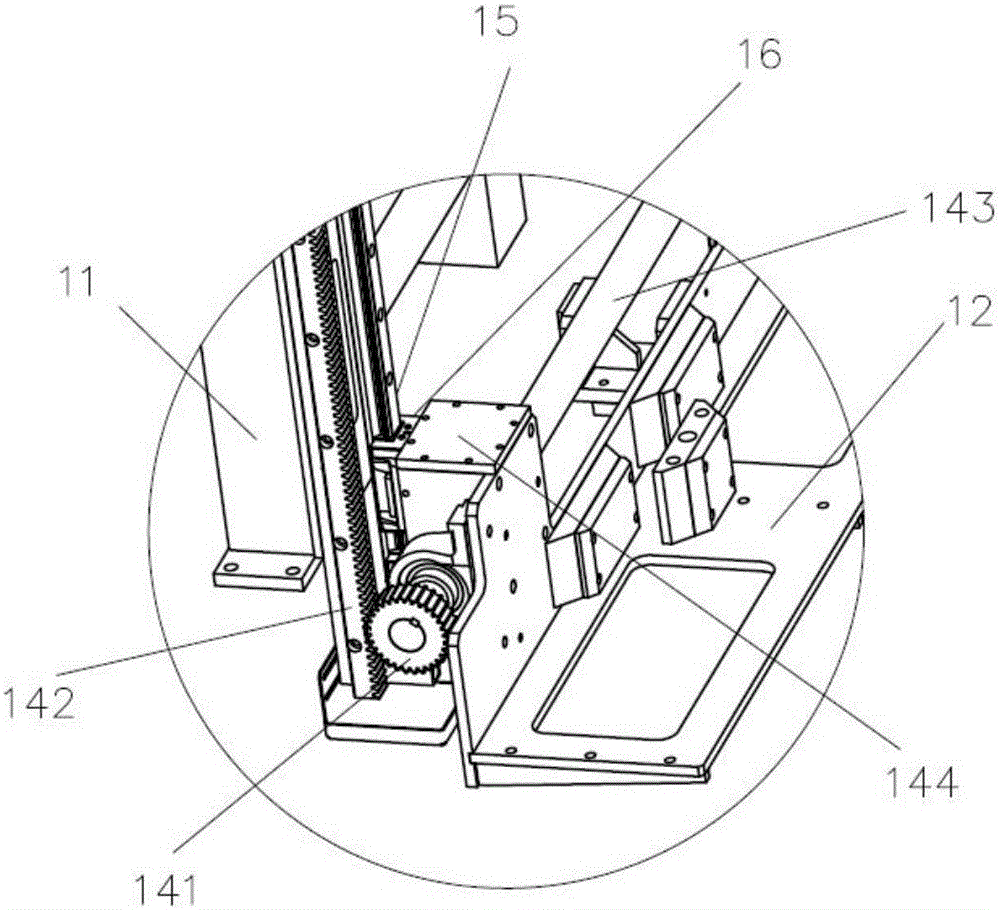

[0034] Please also see Figure 1 to Figure 5 , as shown in the figure, a synchronous lifting device is arranged at the input end of the conveying line 20. The synchronous lifting device 10 includes a frame 11, a lifting frame 12 for placing materials inside the frame 11, and a driving lifting frame 12. The driving mechanism 13 of material frame 12 vertical lifting; The relative both sides on the lifting material frame 12 are provided with linkage mechanism 14, and every group of linkage mechanism comprises two transmission parts that are arranged before and after and the transmission shaft that connects two transmission parts, by adopting transmission shaft will The front and rear two transmission parts are connected, so that the linkage between the transmission parts is realized, and the front and rear positions of one side of the lifting material frame are guaranteed to move at the same time.

[0035] In the present invention, the driving material frame is a rectangular stru...

Embodiment 2

[0047] All the other are the same as in Embodiment 1, the difference is that the lifting material frame 12 has four sides, the linkage mechanism 14 is three groups arranged on the three sides of the lifting material frame, and the output end of the driving mechanism 13 is connected to any side of any linkage mechanism. On one gear, this gear forms a driving gear, and the remaining gears are driven gears. Preferably, the joints of two adjacent groups of linkage mechanisms are in the form of gear meshing, and the gears at this place are 45-degree bevel gears. A transmission member is provided or a conveyor belt is wound around the two gears to transmit the rotation, and there is no specific limitation.

[0048] In addition, the driving mechanism can also be arranged in the middle of the side where no linkage mechanism is arranged, and the specific method is not limited.

Embodiment 3

[0050] All the other are the same as Embodiment 1, the difference is that the linkage mechanism 14 is four groups arranged around the lifting material frame 12, and the output end of the drive mechanism 13 is connected on any gear of any linkage mechanism 14, and the gear forms a driving mechanism. Gears, the rest of the gears are driven gears, preferably the joints of two adjacent groups of linkage mechanisms are in the form of gear meshing, and the gears at this place are 45-degree bevel gears. In other embodiments, a transmission member can also be provided between the two gears or a conveyor belt can be wound around the two gears to transmit the rotation, which is not specifically limited.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com