Flexible Prestressing Fixtures for Shot Peening of Large Wall Panel Workpieces

A technology for shot peening and large-scale wall panels, which is applied in the direction of manufacturing tools, metal processing equipment, storage devices, etc., can solve the problems of uncollected data, no description or report found, etc., and achieves convenient and labor-saving clamping and pre-bending. Apply uniform and controllable, easy to operate and labor-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

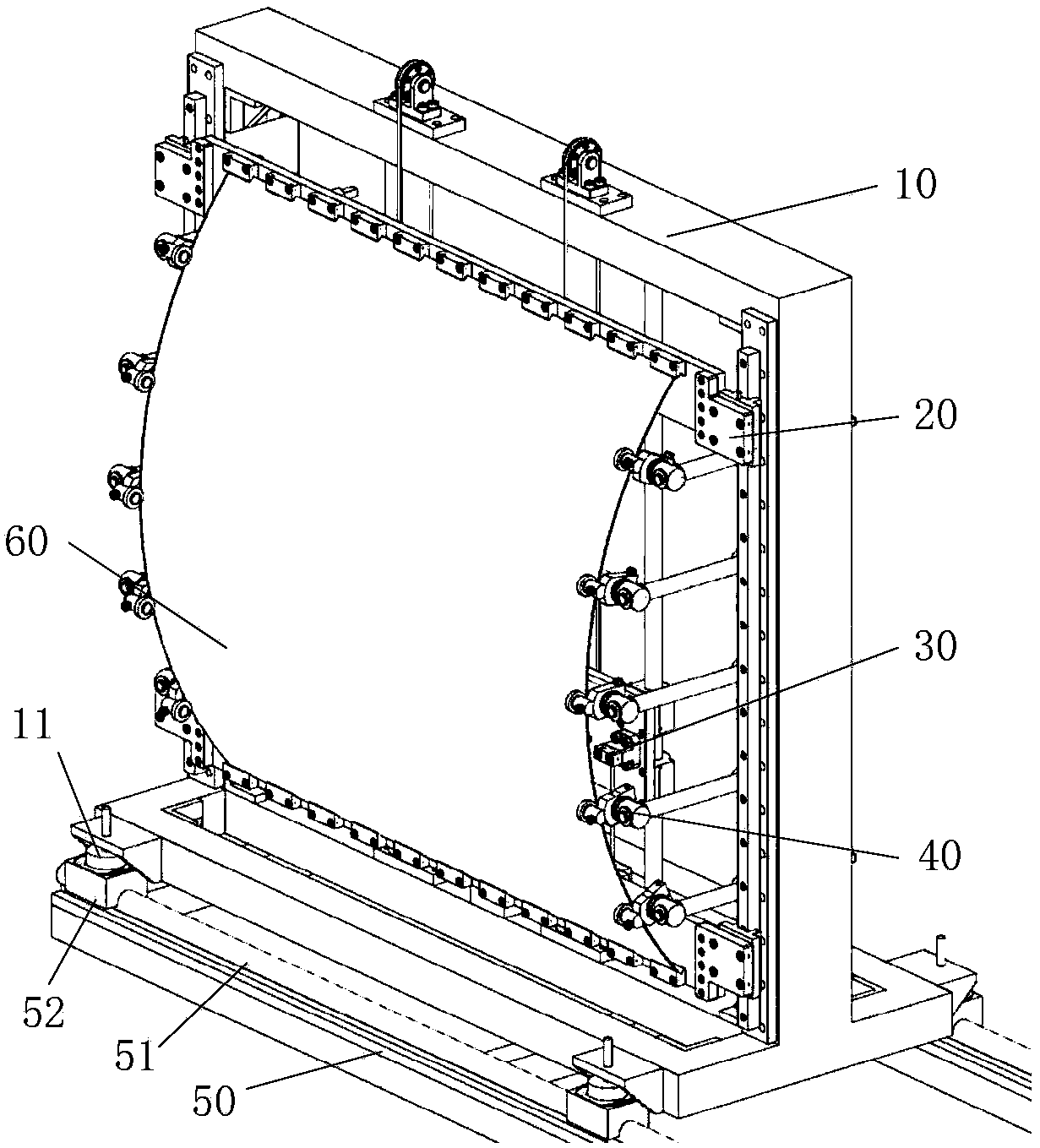

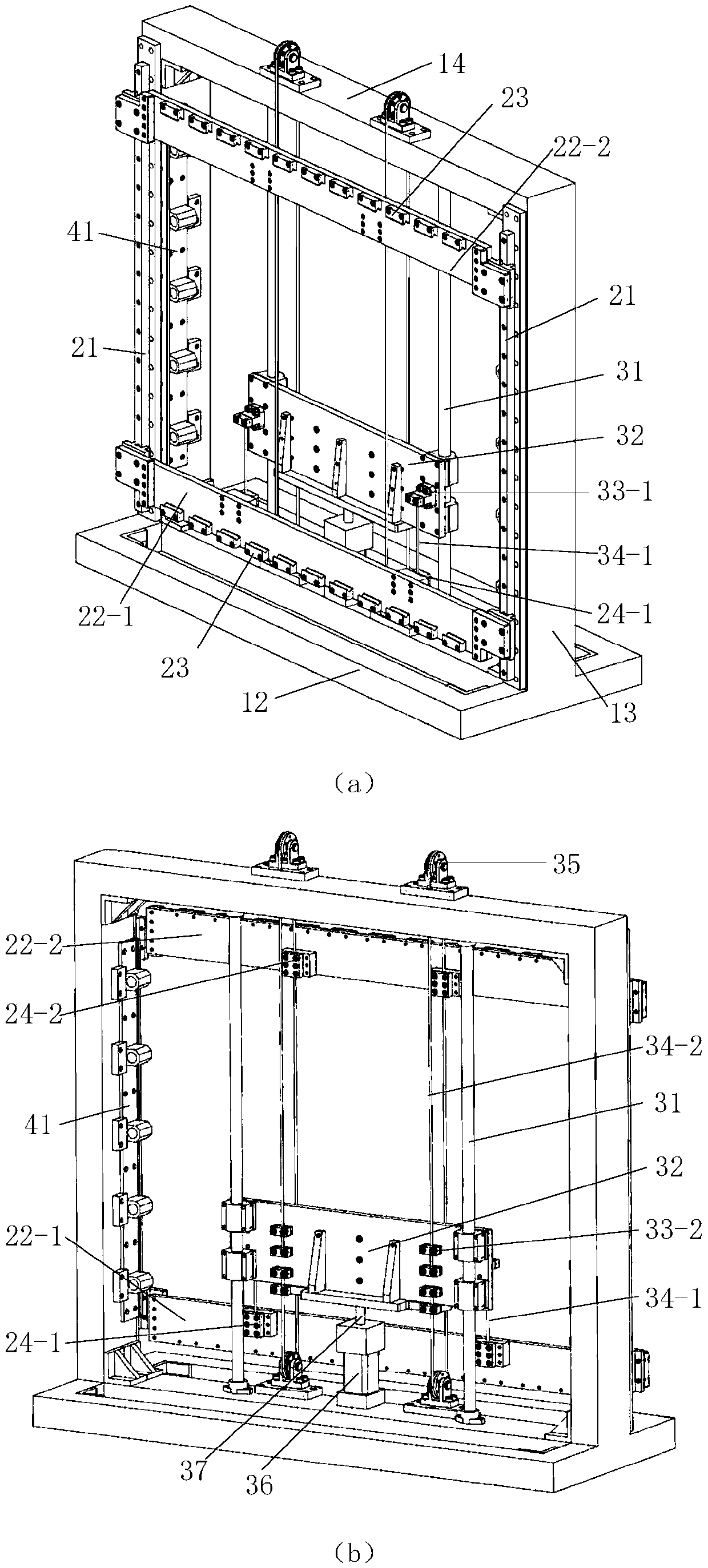

[0036] This embodiment provides a flexible prestressed fixture for shot peening of large wallboard workpieces, which has a rigid frame for support, and the rigid frame is equipped with upper and lower extrusion modules for bending wallboard workpieces, The lifting control module used to control the upper and lower extrusion modules and the elastic pre-bending module used to control the bending shape of the workpiece, the rigid frame is arranged on the horizontal guide rail and can move along the horizontal guide rail.

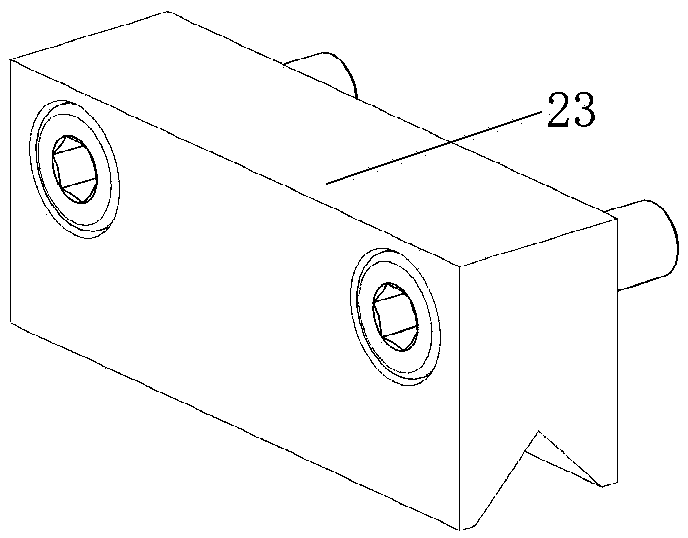

[0037] Further, the rigid frame has a rigidly connected base, a left column, a right column and an upper beam, and is installed on the horizontal guide rail through adjustable horizontal legs. The outer sides of the left column and the right column are respectively provided with connection structures, which are used to realize the splicing of two or more flexible prestressed clamps in the length direction.

[0038] Further, the upper and lower extrusion modules...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com