Double sided ring spinning machine

A technology of ring spinning machine and spinning machine, which is applied in the direction of spinning machine, continuous winding spinning machine, textile and papermaking, etc., which can solve the problems of occupying space, reduce workload, improve heat loss, The effect of simplifying assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

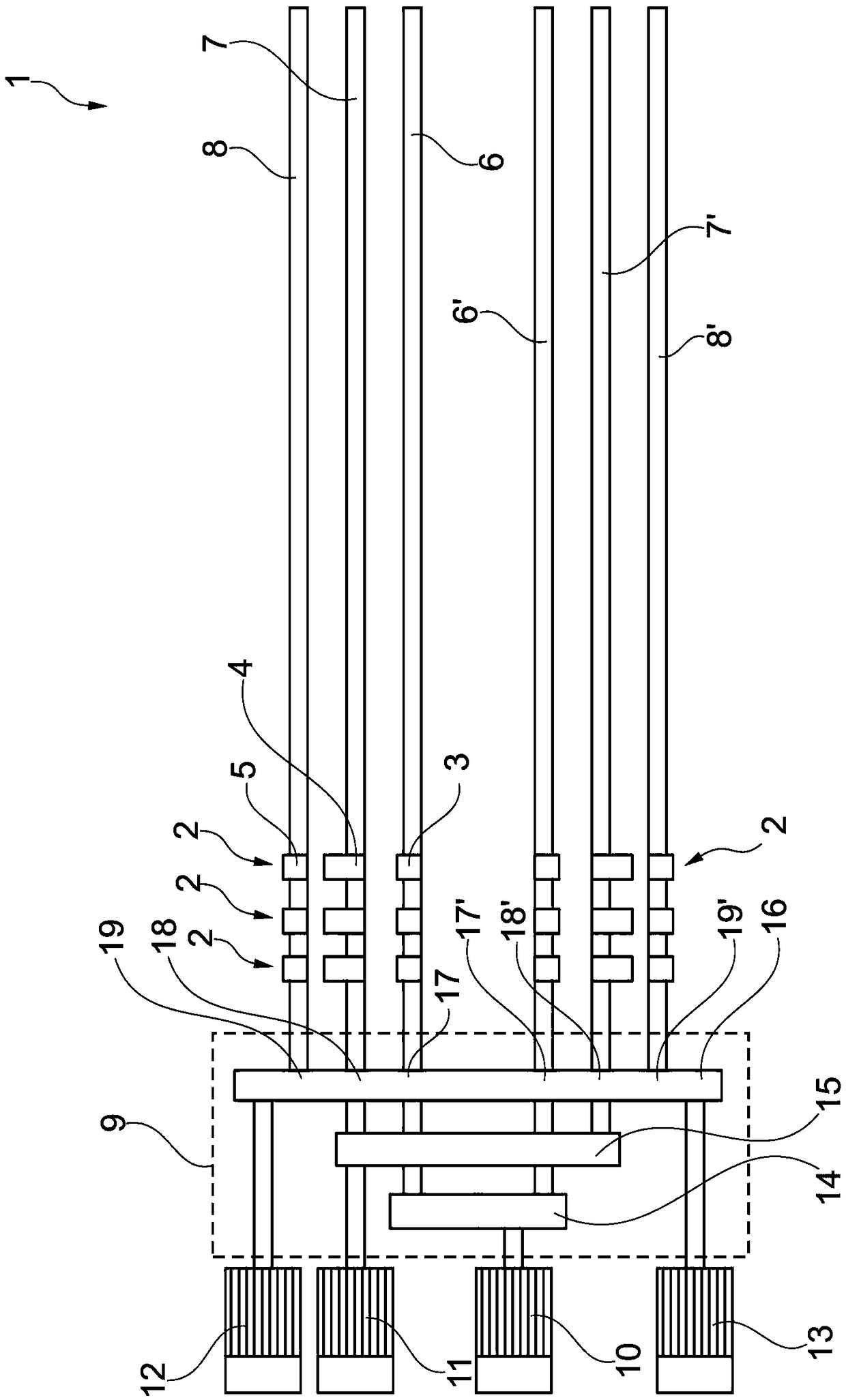

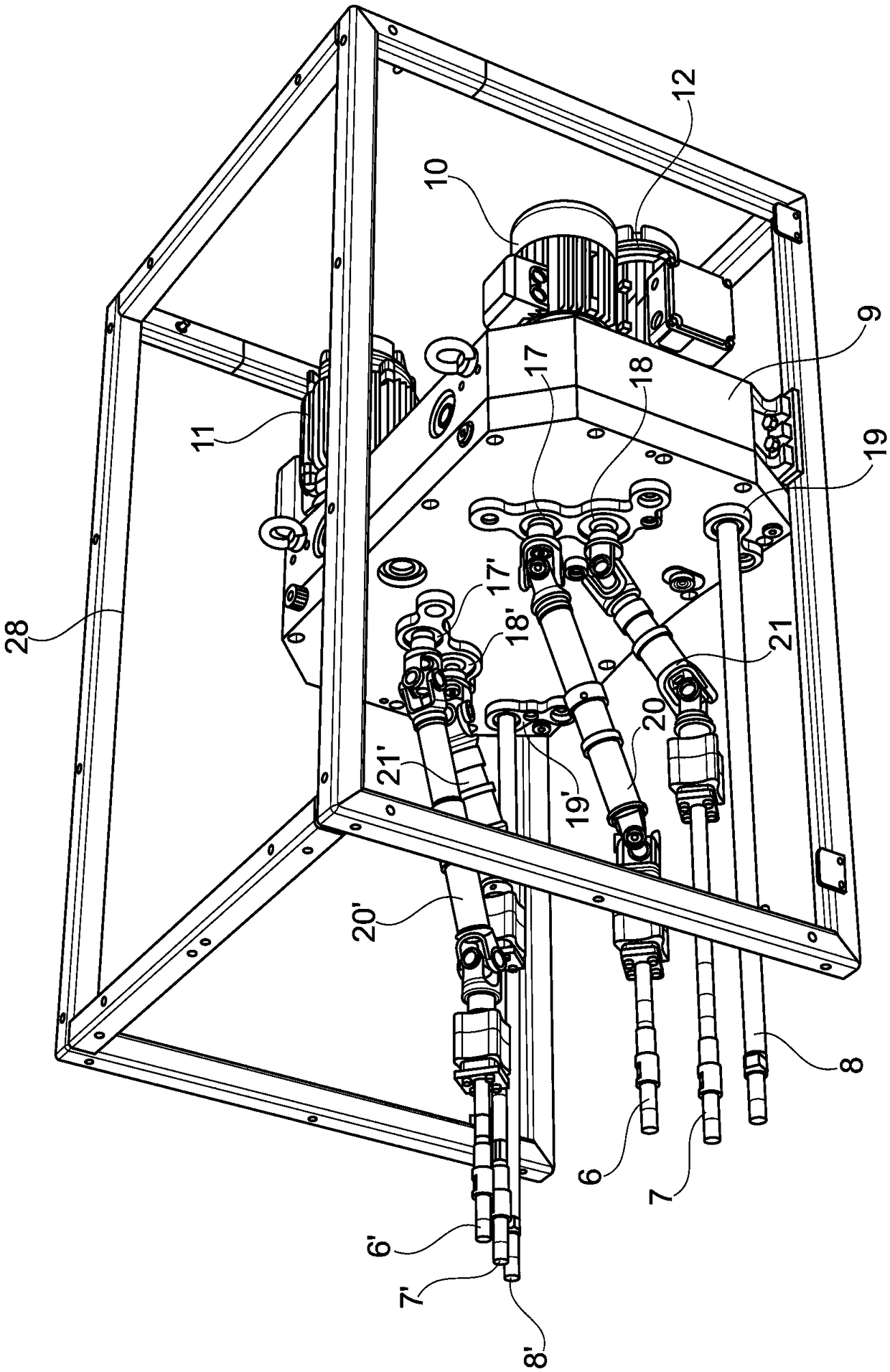

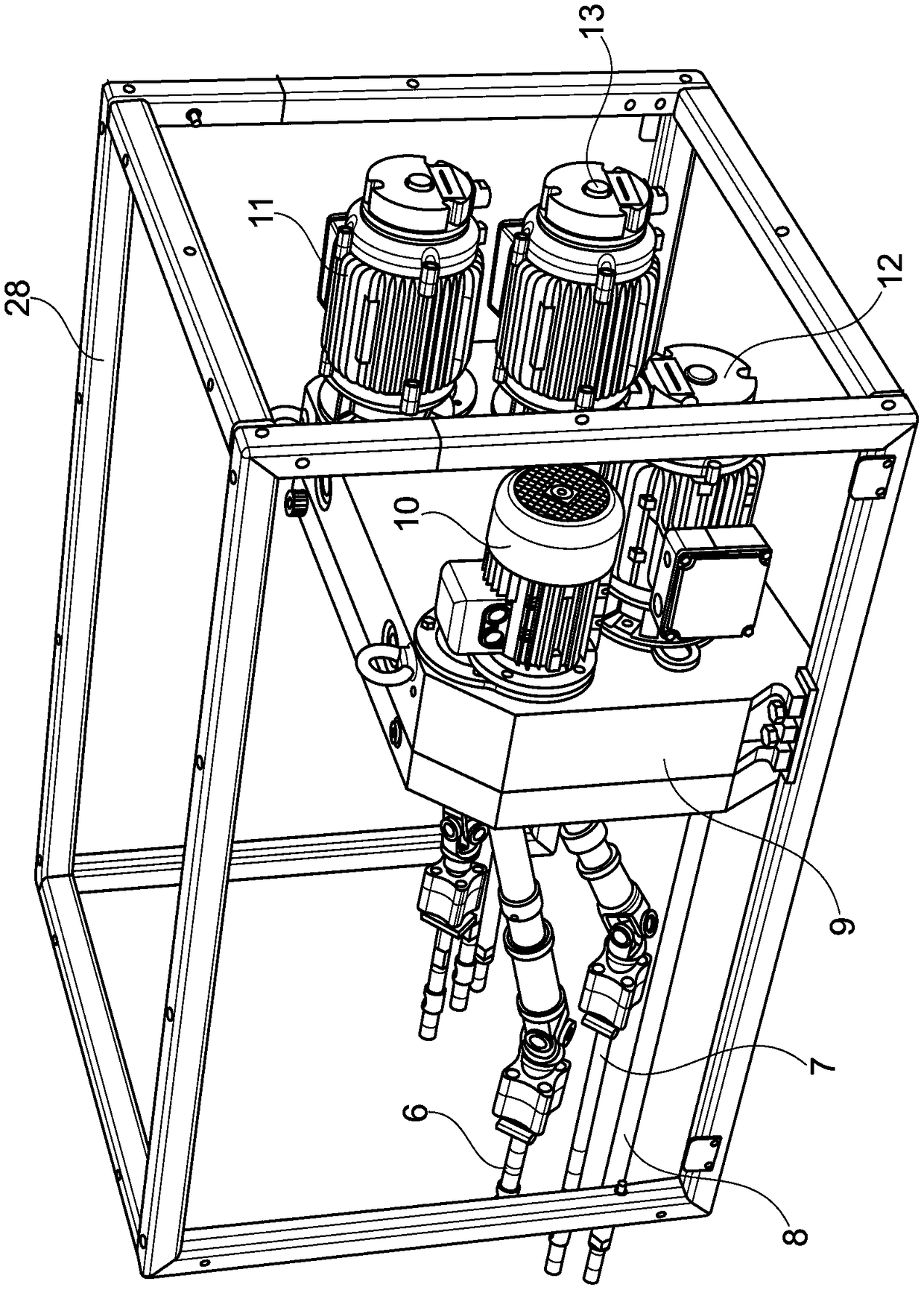

[0020] figure 1 A double-sided ring spinning machine 1 according to the invention is shown. As ring spinning machines are generally known, the drawings are limited to the necessary parts for explaining the invention. Each side of the ring spinning machine comprises a plurality of adjacently arranged drafting devices 2, only three of which are shown here. Only the feed roller 3, the lower intermediate roller 4 and the lower output roller 5 of the drafting device 2 are shown. The lower feed roller 3, the lower middle roller 4 and the lower output roller 5 on one side are arranged adjacent to each other on the shaft respectively and form the feed roller zipper 6,6', the middle roller zipper 7,7' and the output roller zipper 8,8 '. The lower feed roller 3, the lower intermediate roller 4 and the lower output roller 5 all have independent drives with independent transmissions and one or more independent motors. The lower feed roller 3 is driven by the shafts of the lower feed r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com