A self-adjusting glass bracket

An automatic adjustment and glass technology, which is applied in escalators, transportation and packaging, etc., can solve the problems of low adjustment efficiency and inability to automatically adjust the thickness of the clamp groove, and achieve the effect of improving automatic control, reducing manual installation errors, and adjusting stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

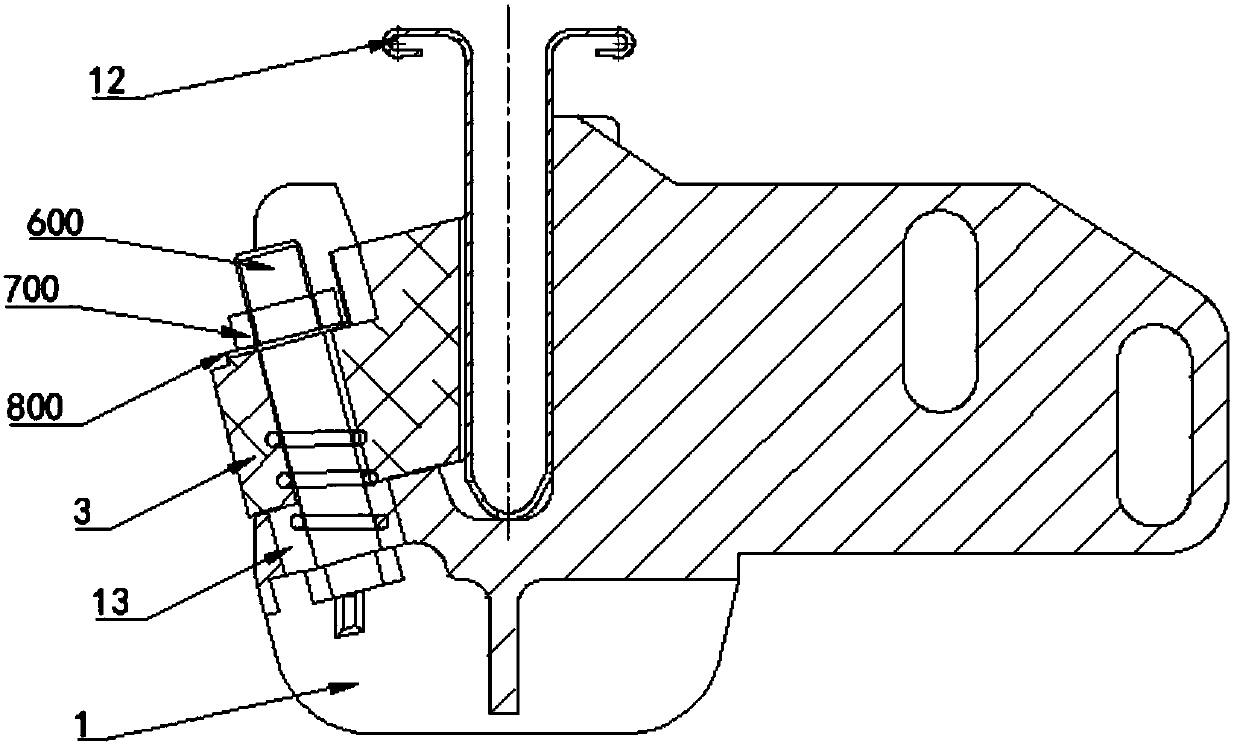

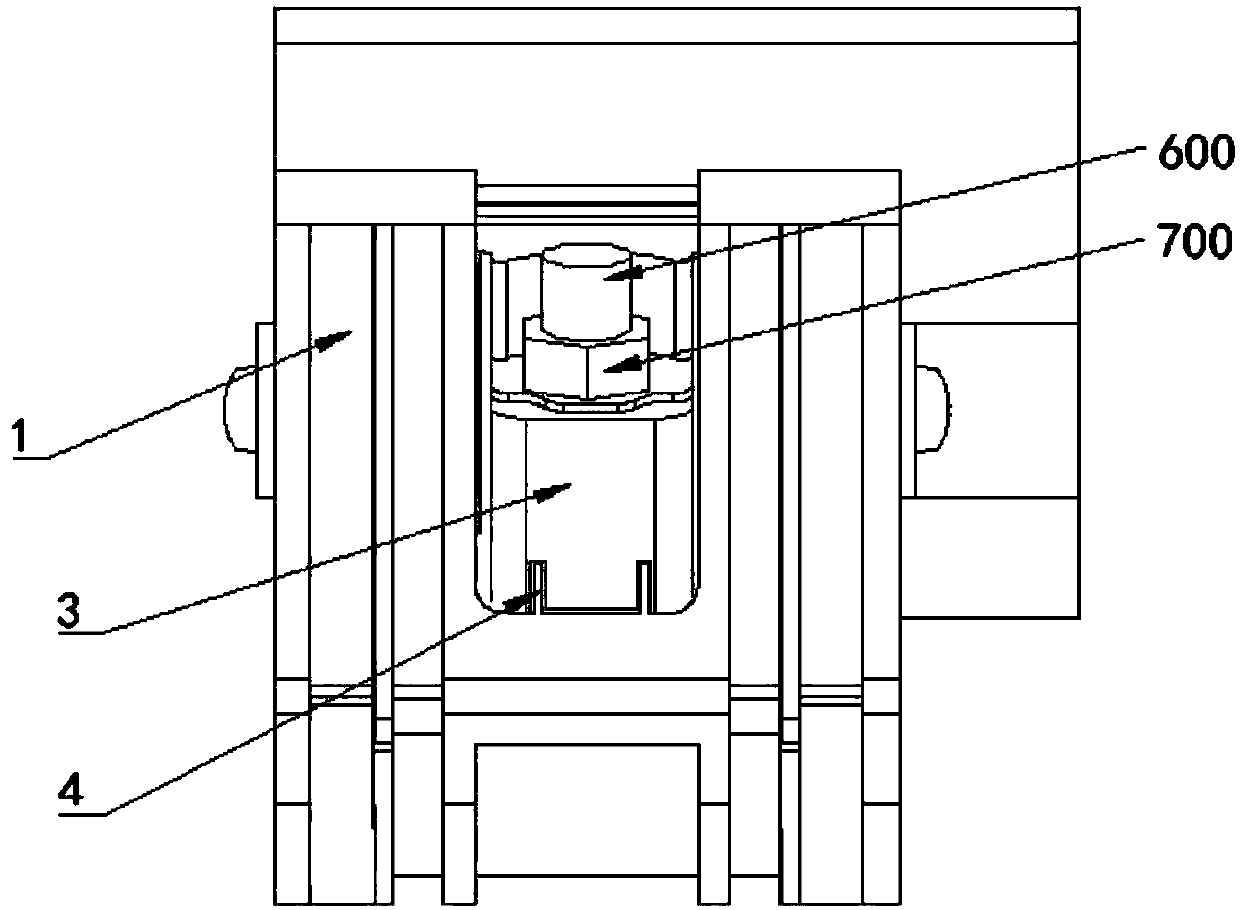

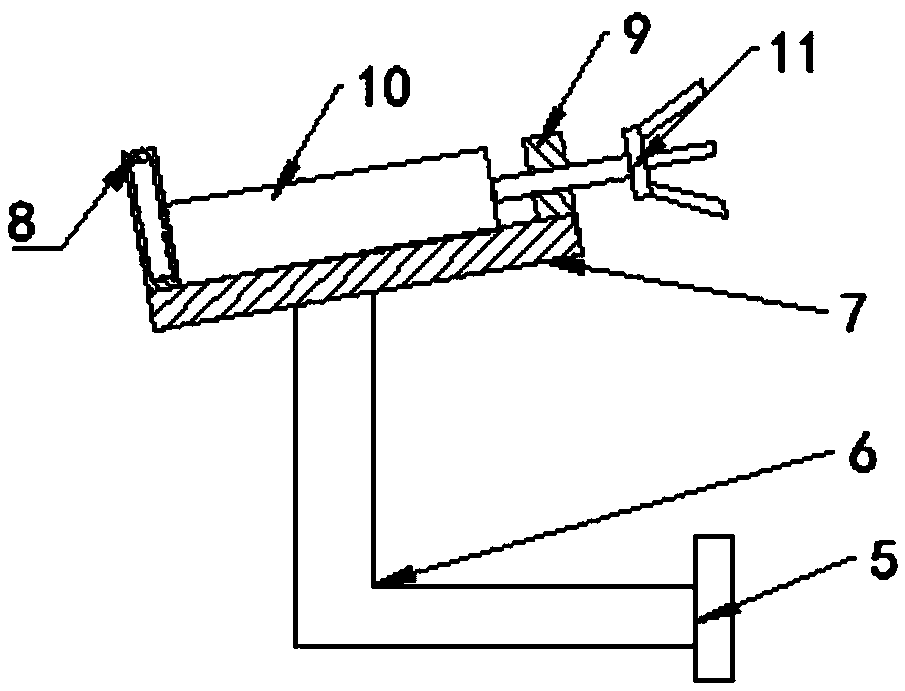

[0027] This embodiment discloses an automatic adjustment glass bracket, such as figure 1 As shown, the self-adjusting glass bracket includes a glass bracket body 1, and the glass bracket body 1 is provided with a wedge-shaped notch and a clamping handle, and the clamping handle is arranged at the rightmost end of the glass bracket body 1 for connecting with the truss. The wedge-shaped notch is divided into a hypotenuse and a vertical side, and a glass clip 12 is placed in the notch; a top pressure piece is also provided on the glass support, and the top pressure piece is located at the hypotenuse of the wedge-shaped notch; the top pressure piece includes a wedge 3. Bolts 600, nuts 700 and was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com