Manufacturing method of roll mold and roll mold

A manufacturing method and roll mold technology, applied in the field of roll molds, can solve problems such as low production efficiency and achieve the effect of improving manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

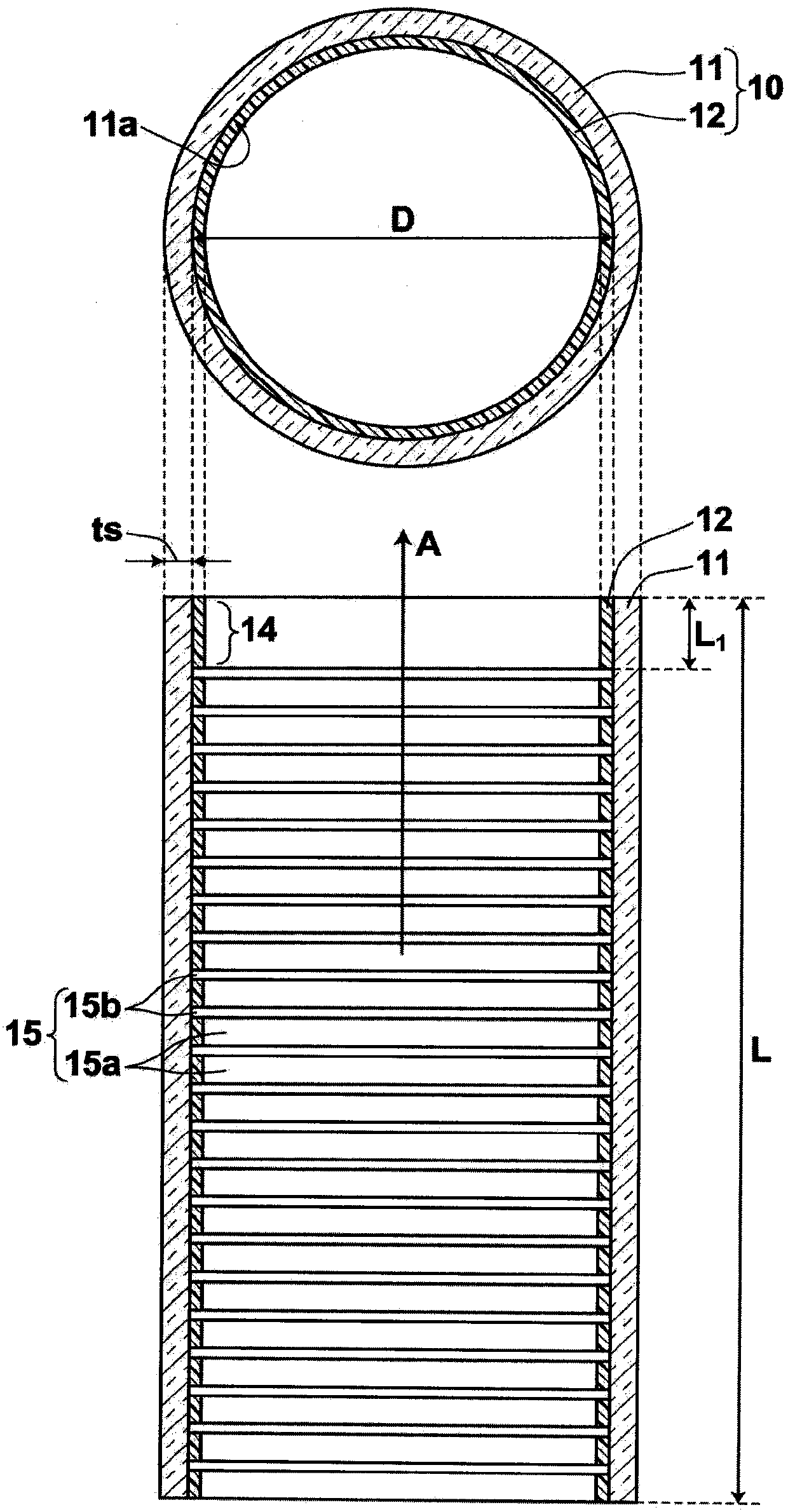

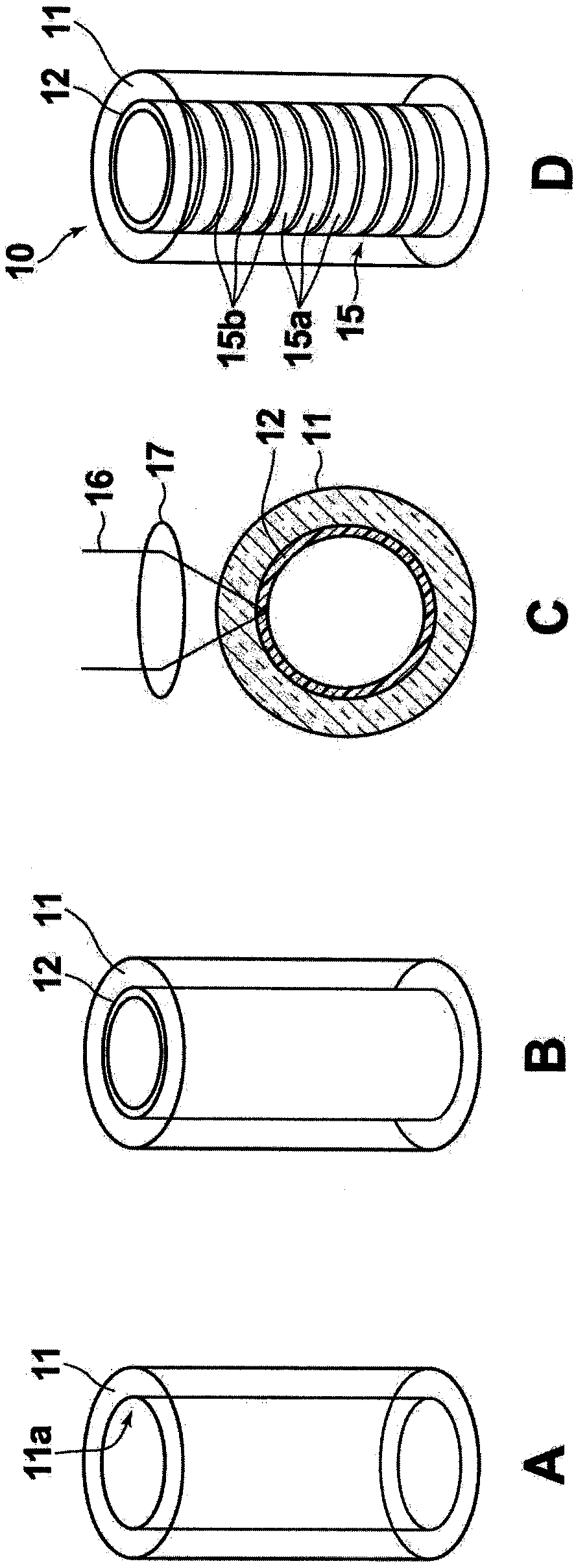

[0060] Hereinafter, embodiments of the present invention will be described using the drawings, but the present invention is not limited to these embodiments. In addition, in order to facilitate confirmation and understanding of the invention, the proportions and the like of each component in the drawings are different from the actual proportions.

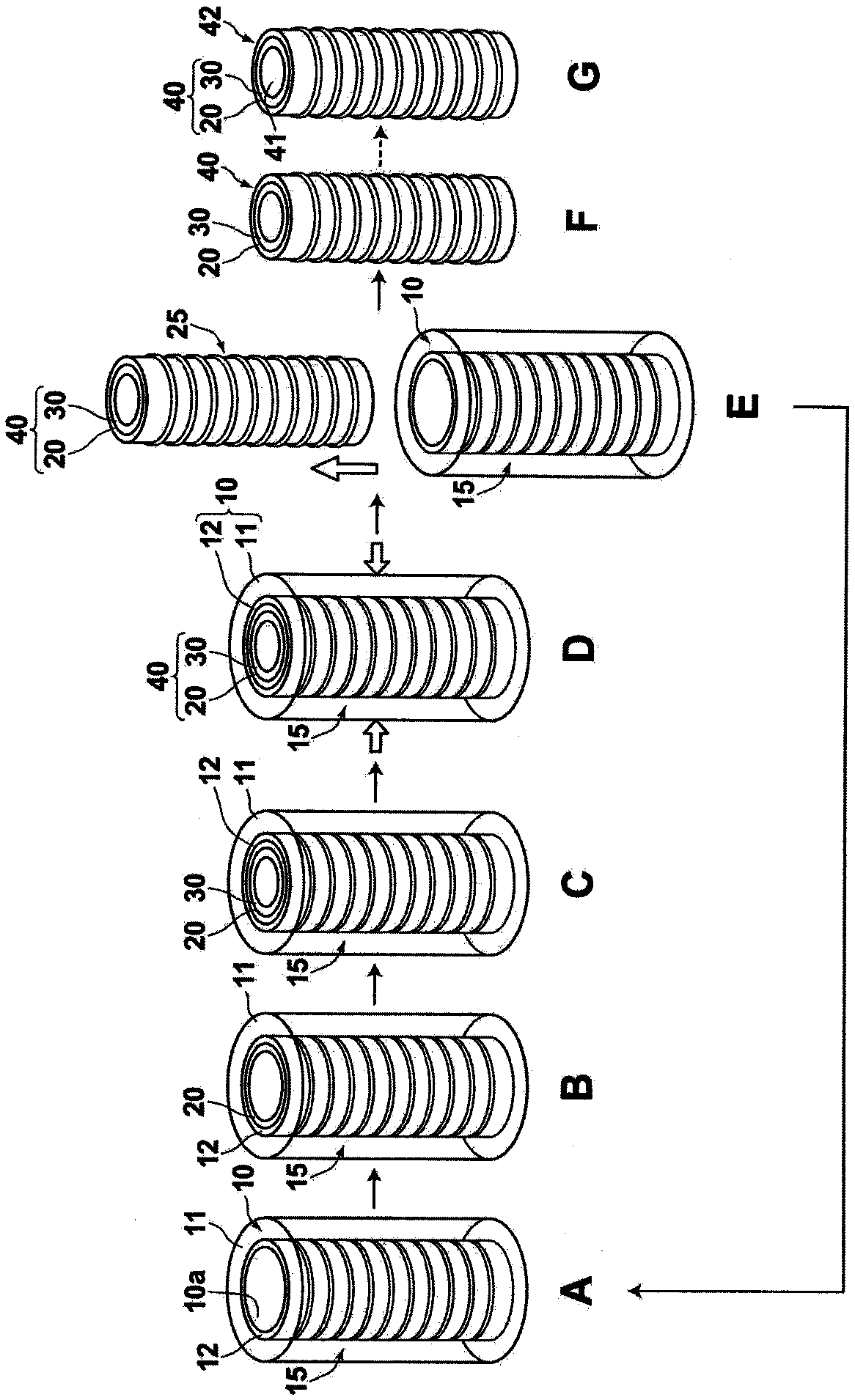

[0061] figure 1 It is a figure which schematically shows the manufacturing method of the roll mold of this embodiment.

[0062] The manufacturing method of the roller mold of the present embodiment is as figure 1 As shown, the method is as follows: prepare a roll original plate 10 formed with a concave-convex pattern 15 transferred to an inner wall surface 10a, wherein the inner wall surface 10a forms a cylindrical hollow part (step A); form a metal layer 20 on the inner wall surface 10a ( Step B); forming a peeling auxiliary layer 30 having a thermal expansion coefficient larger than that of the metal layer 20 on the surface of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com