Nut tightening machine

A technology for fastening machines and nuts, applied in the direction of screwdrivers, motor tools, light motorized devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

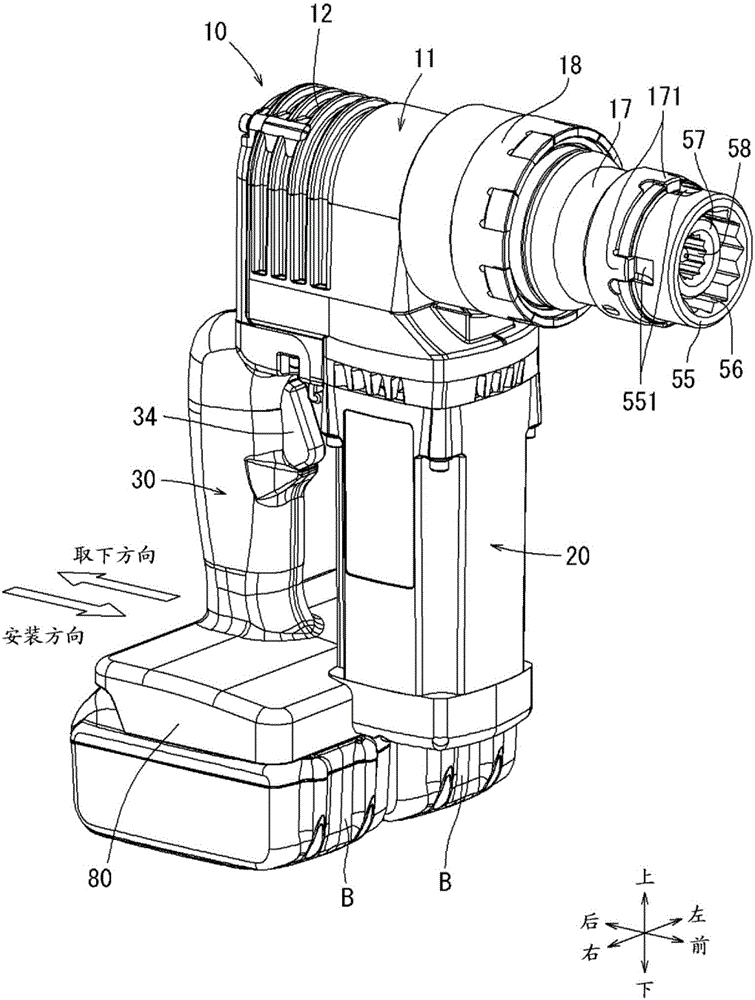

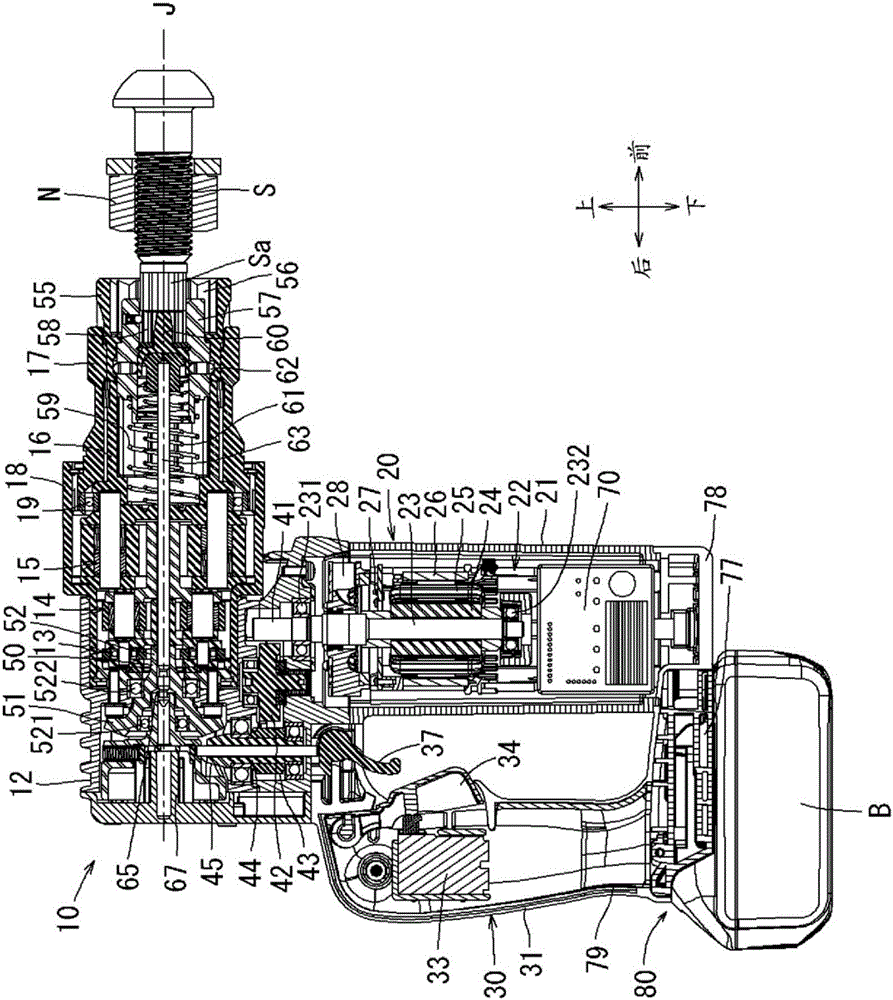

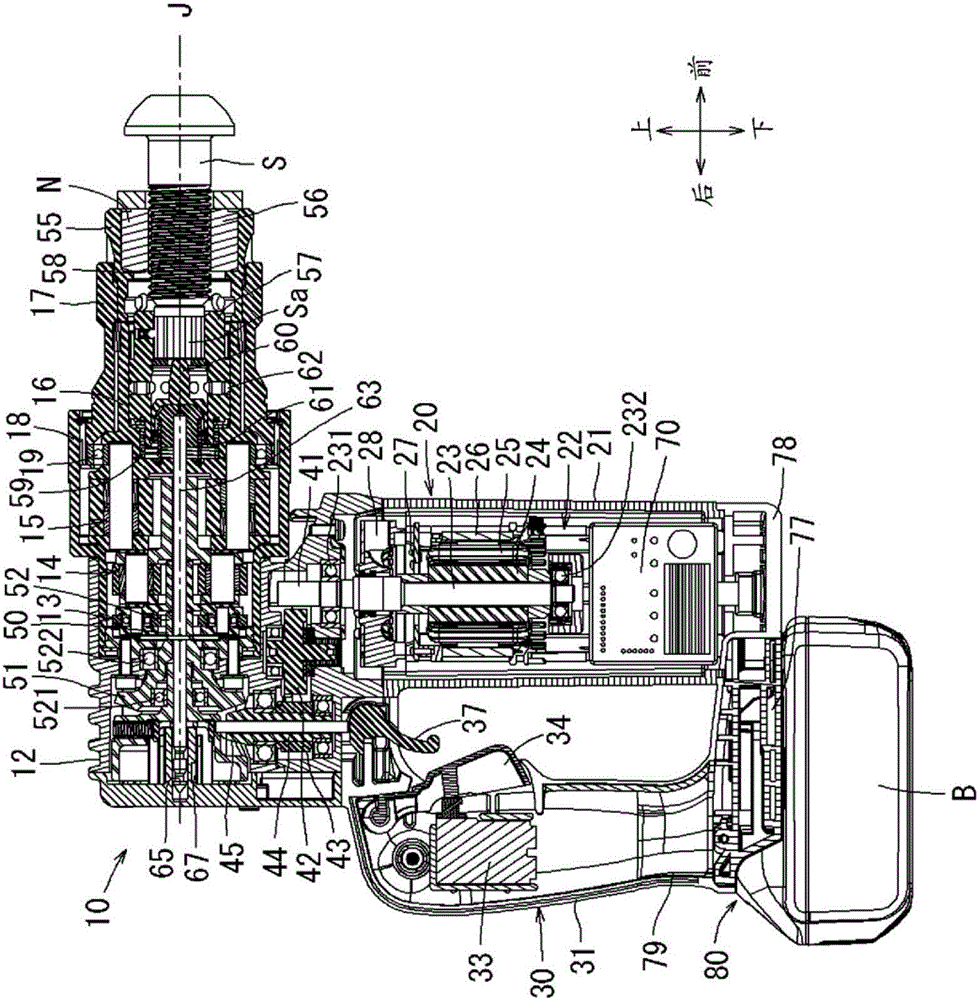

[0024] Hereinafter, an embodiment of a nut tightening machine for carrying out the present invention will be described. figure 1 The perspective view of is three-dimensionally shows the overall appearance of the nut tightening machine 10. figure 2 as well as image 3 The cross-sectional view of FIG. 1 shows the internal construction of the nut tightening machine 10 . also, figure 2 The state before the end portion Sa of the shear bolt S is inserted into the inner socket 57 is shown, image 3 The state where the tip part Sa of the shear bolt S is inserted into the inner socket 57 is shown.

[0025] In addition, when describing the nut tightening machine 10 below, it demonstrates based on the direction of front, back, up, down, left and right described in drawing. The illustrated nutrunner 10 is also a tool called a torsional shear wrench. This nut tightening machine 10 is used for screw-fastening a hexagonal nut N to a shear bolt S. As shown in FIG. In other words, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com