Mandrel Mechanism and Oil Filling Method of Telescope Primary Mirror Based on Static Pressure Principle

A telescope and mandrel technology, applied to bearings, shafts and bearings, mechanical equipment, etc., can solve problems such as axial support and decoupling of the main mirror mandrel of the telescope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

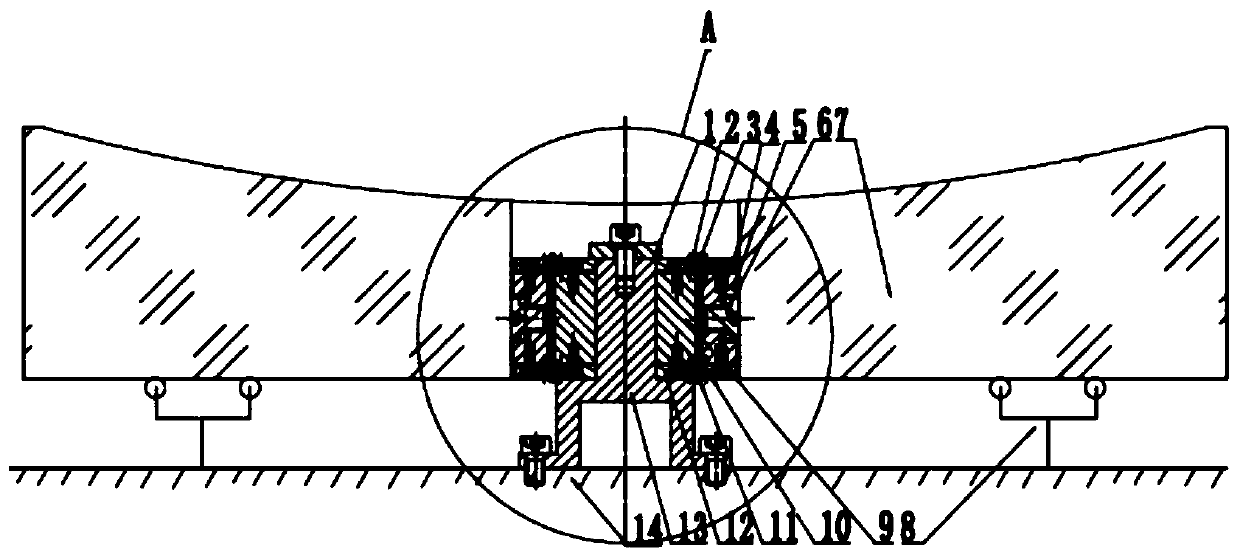

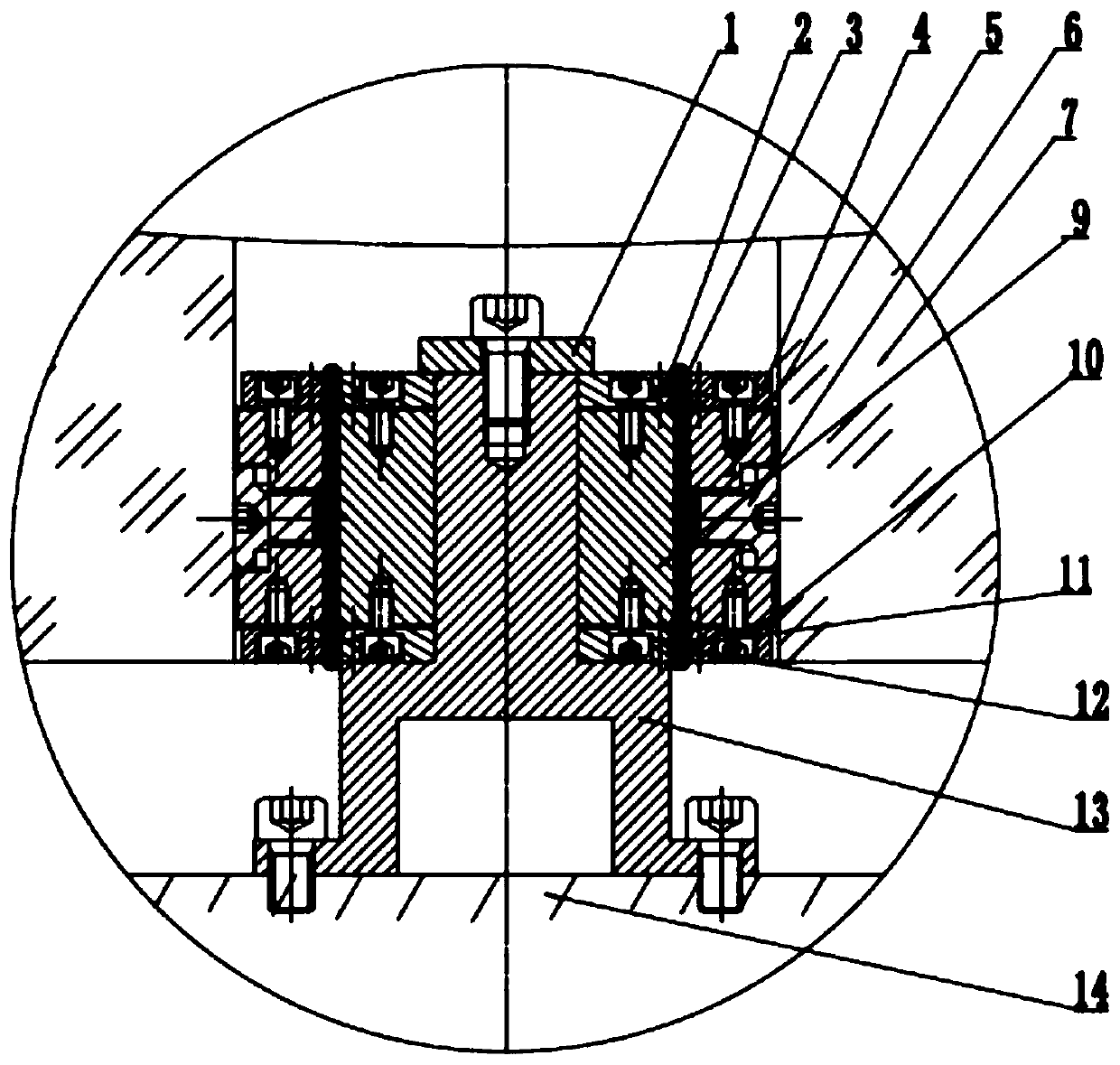

[0014] Specific implementation mode 1. Combination Figure 1 to Figure 4 Describe this embodiment, the main mirror mandrel mechanism of the telescope based on the principle of static pressure, including the mandrel pressure block 1, the inner pressure plate 2 of the upper film, the outer pressure plate 4 of the upper film, the outer ring of the mandrel 5, the inner hexagonal plunger 6, Mandrel inner ring 9, lower film outer pressure plate 10, rolling film 11, lower film inner pressure plate 12 and mandrel column 13. The mandrel assembly is mainly composed of a mandrel inner ring 9 , a mandrel outer ring 5 and a mandrel column 13 . Wherein the mandrel outer ring 5 is in contact with the middle hole of the primary mirror 1, and the two are bonded together by glue. The mandrel column 13 is mounted on the mirror chamber 14 by screws, and the mandrel inner ring 9 is fixed on the mandrel column 13 by the mandrel pressing block 1 . The mandrel inner ring 9 and the mandrel outer rin...

specific Embodiment approach 2

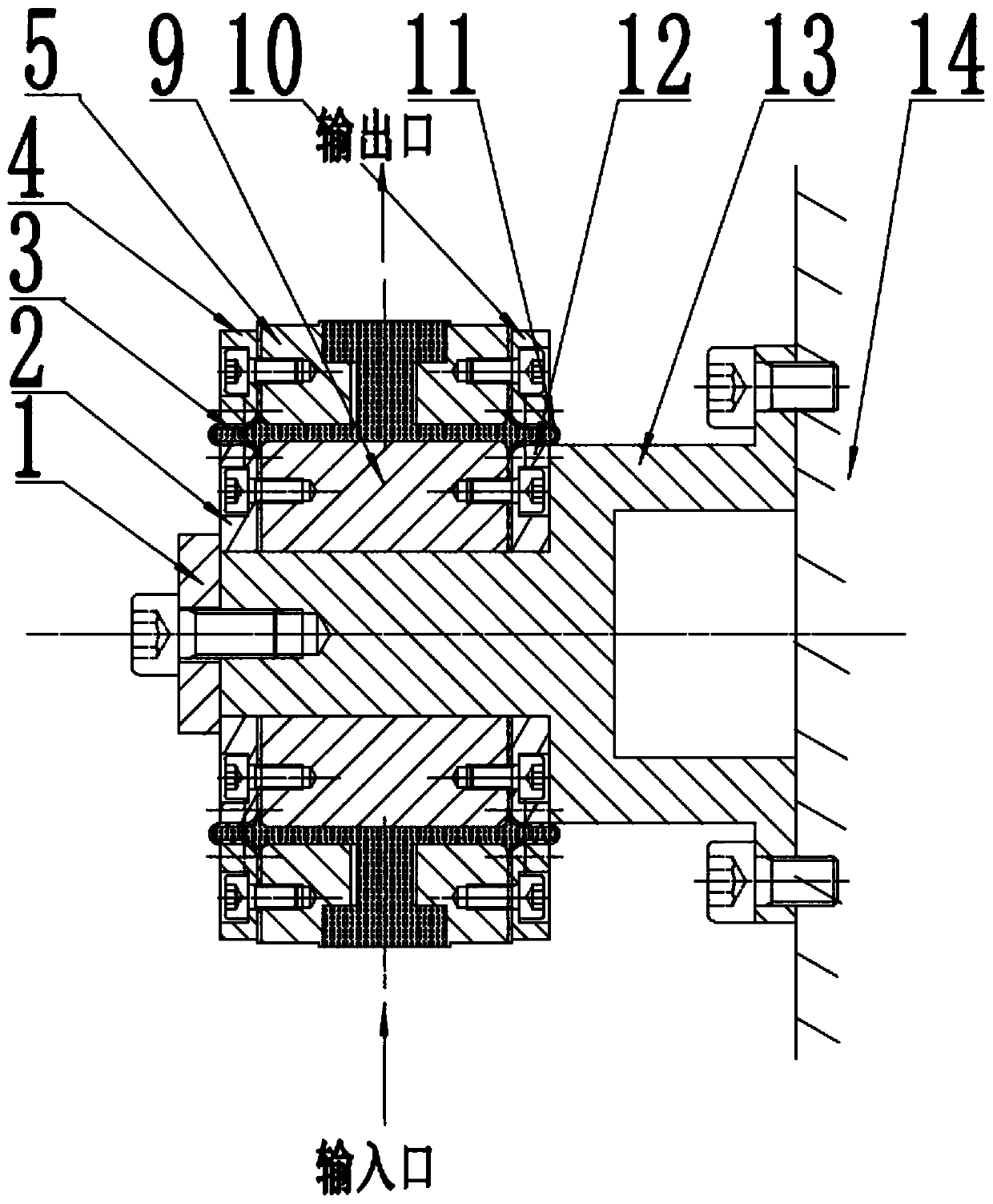

[0016] Specific embodiment two, combine image 3 and Figure 4 Illustrate this embodiment, this embodiment is the oiling method of the telescope main mirror mandrel mechanism based on static pressure principle described in specific embodiment one, this method realizes through the following process:

[0017] First place the mandrel mechanism horizontally, remove the inner hexagonal plunger 6, and then pass image 3 Fill oil at the oil injection input port given in , the low temperature hydraulic oil flows upward gradually through the lowest point, and finally flows out from the oil injection output port. After filling up, at first the hexagonal plunger 6 of the oil injection output port is screwed into the mandrel outer ring 5, and the oil injection output port is sealed.

[0018] Then the mandrel mechanism is rotated and the original oil injection inlet is placed upwards. After standing for a period of time (generally about seven days), the oil injection inlet is also sealed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com