Optical device for measuring wavelength and control method thereof

An optical device and wavelength technology, applied in the field of optical prisms, to achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

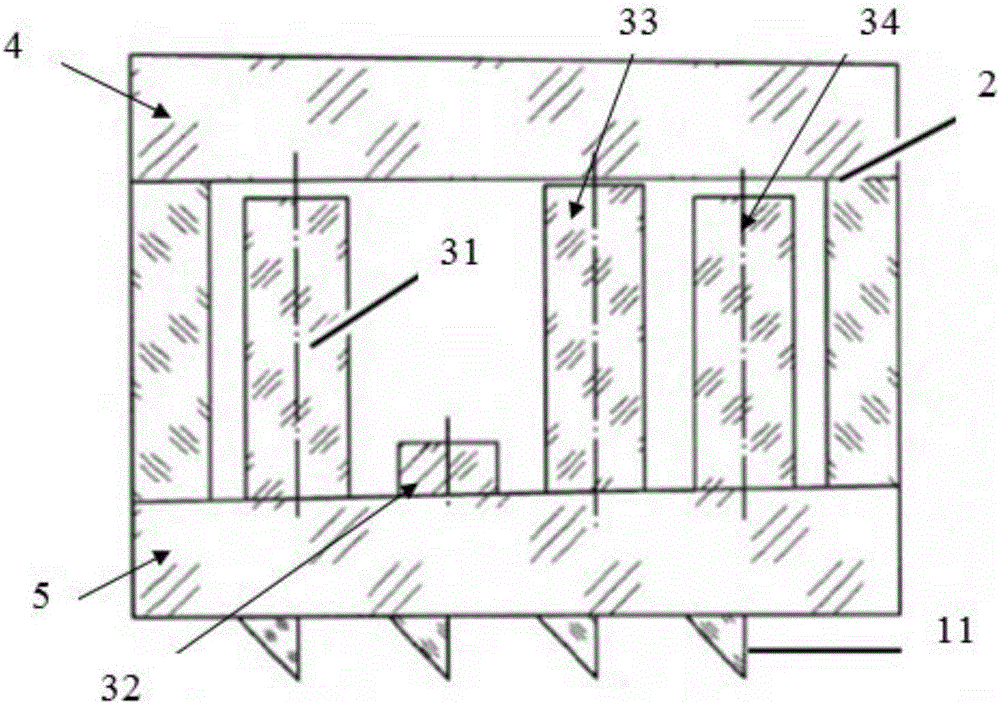

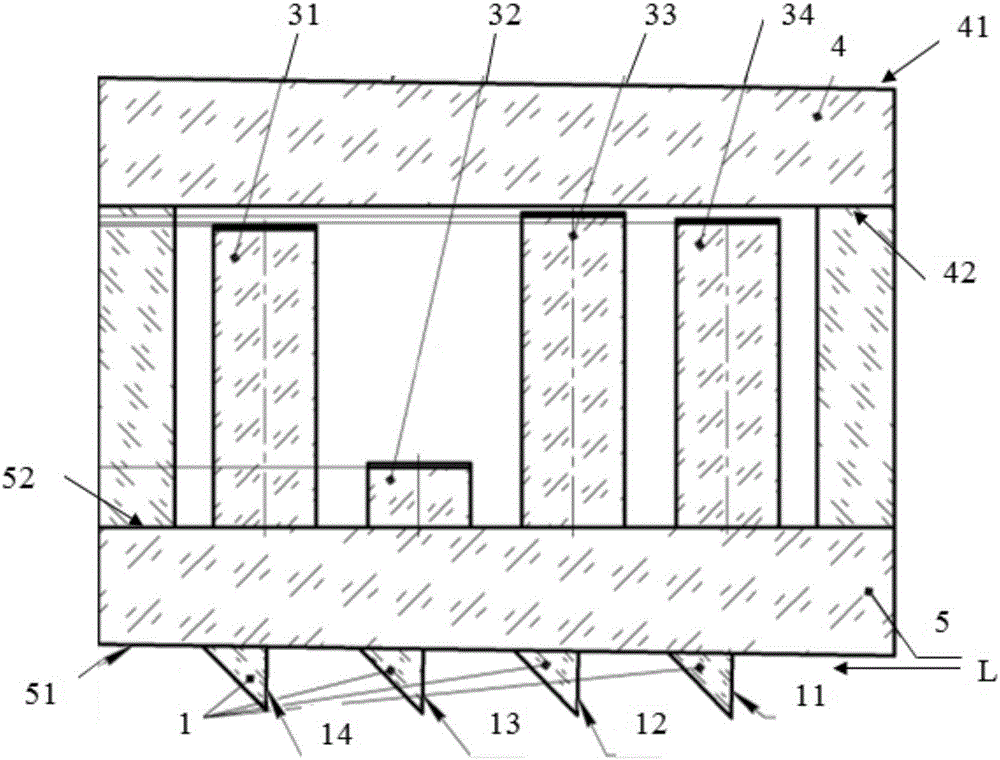

[0024] like figure 1 , figure 2 , Figure 5 , Image 6 A structural diagram of an optical device for measuring wavelengths is provided for an embodiment of the present invention, including a cavity provided with a peripheral wall 2, an upper cover 4 and a lower cover 5, and the lower cover of the cavity is arranged The four prism-shaped prisms 1 are respectively prism 11, prism 12, prism 13, and prism 14, and the prisms corresponding to the prisms arranged inside the cavity and on the inner surface 52 of the lower cover are respectively prism 31, prism 32, prism 33, prism 34. Make the light to be measured pass through the prism 1, the lower cover plate 5, the prism 3 and the upper cover plate 4 to form light rays with only different optical paths for measurement.

[0025] A right-angled surface of the prism 1 is the incident surface of the light L to be measured entering the glass from the air from right to left, and the inclined surface of the prism 1 is the exit surface ...

Embodiment 2

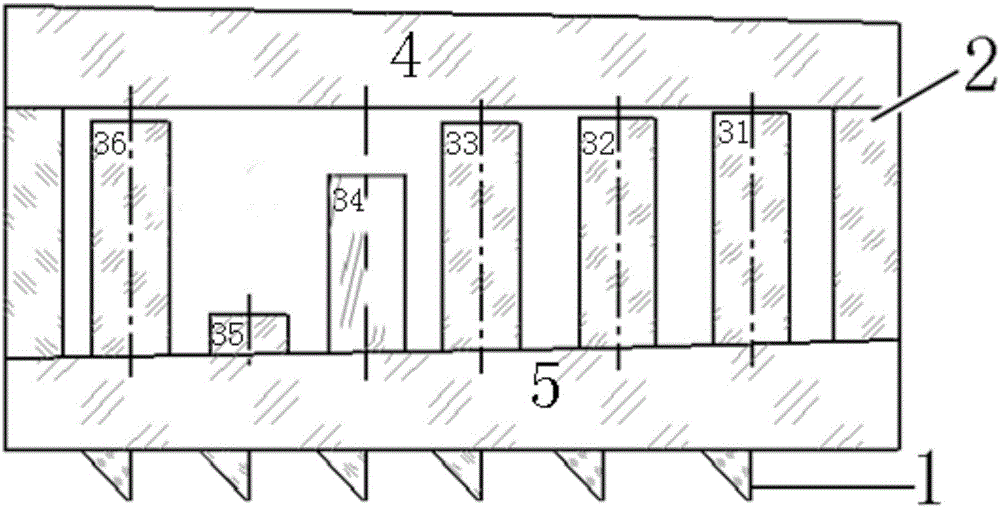

[0033] like image 3 , Figure 4 , Figure 5 A structural schematic diagram of an optical device for measuring wavelengths is provided for an embodiment of the present invention, including a cavity provided with a peripheral wall 2, an upper cover 4 and a lower cover 5, and the lower cover of the cavity is provided with Six prism-shaped prisms 1, respectively prism 11, prism 12, prism 13, prism 14, prism 15, and prism 16, are arranged inside the cavity and on the inner surface 52 of the lower cover corresponding to the prisms. The prisms are respectively prism 31, prism 32, prism 33, prism 34, prism 35, and prism 36, so that the light to be measured is formed after passing through prism 1, lower cover plate 5, prism 3 and the upper cover plate 4. light path for measurement.

[0034] A right-angled surface of the prism 1 is the incident surface of the light L to be measured entering the glass from the air from right to left, and the inclined surface of the prism 1 is the exi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com