High-performance cargo oil tank sluice valve

A high-performance technology for cargo oil tanks, applied in sliding valves, valve details, valve devices, etc., can solve problems such as valve leakage, easy scratches, and large operating torque, so as to improve service life, reliability, and operation The effect of small torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

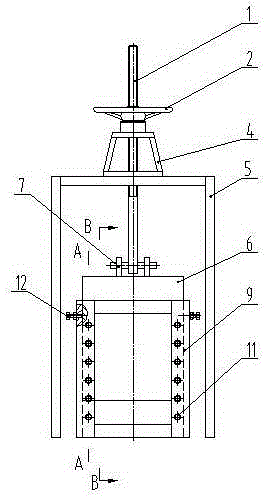

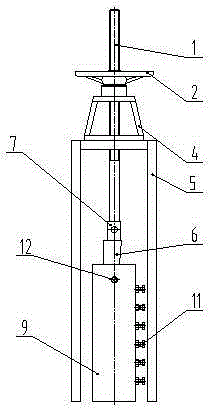

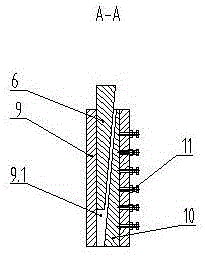

[0019] The high-performance cargo oil tank gate valve shown in the accompanying drawings includes an adjusting screw 1, a hand wheel 2, a support seat 4, a frame 5, a gate plate 6, a lifting lug 7, a gate seat 9, and a wedge 10; the support seat 4 is fixedly connected to the frame 5 on the upper beam; the lifting lug 7 is fixedly connected to the upper end of the gate plate 6; the adjusting screw 1 is vertically placed, runs through the support seat 4, and the beam above the frame 5, the upper end is threaded with the handwheel 2, and the lower end is hinged with the lifting lug 7; Both the plate 6 and the gate seat 9 are placed in the frame 5; the gate plate 6 is placed vertically, inserted into the vertical guide rail groove 9.1 of the gate seat 9 from top to bottom, and fits with the guide rail groove 9.1, and can be moved up and down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com