Magnesium oxide board template feeding device and magnesium oxide board loading method

A technology of glass magnesium board and formwork, which is applied in the directions of transportation and packaging, unstacking of objects, conveyors, etc., can solve the problems of narrow application range and difficult thickness of glass magnesium board, and achieve continuous production, save production time, and operate Labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

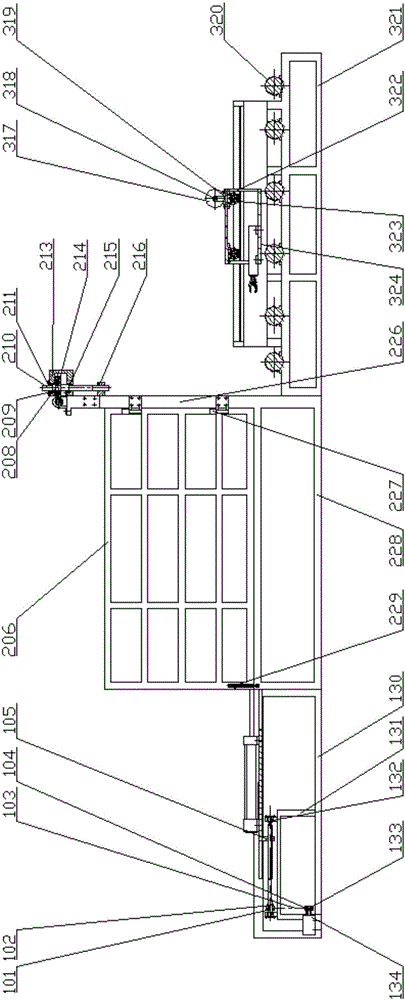

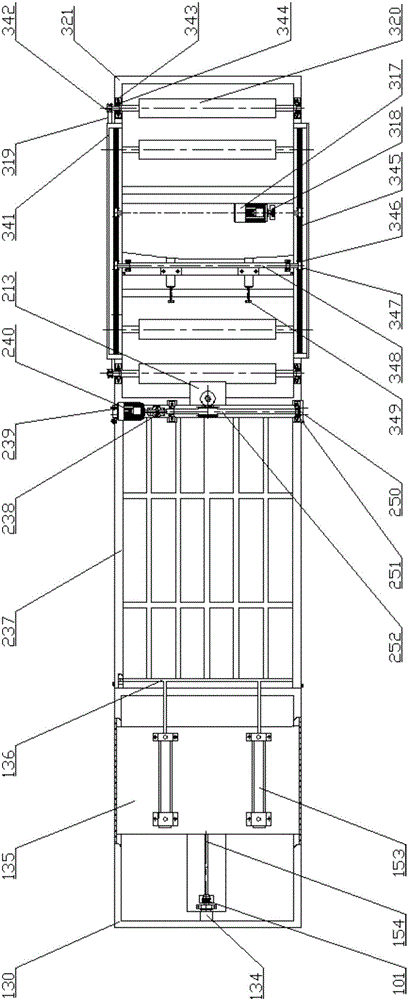

[0041] Such as figure 1 and figure 2 The shown formwork loading device includes a push plate module, a plate storage module and a plate pull module. The plate storage module neatly stacks the glass magnesium plate template, the push plate module pushes the bottom glass magnesium plate form neatly stacked in the plate storage module forward for a certain distance, and the pull plate module pushes the formwork pushed out by the push plate module from the storage The module is pulled out and placed on the glass magnesium board production line.

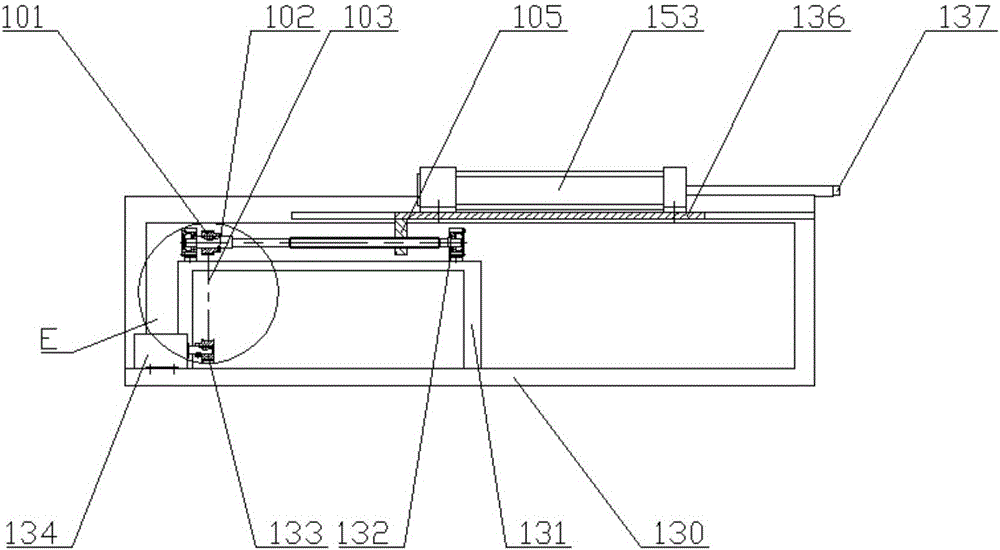

[0042] Such as image 3 , Figure 4 and Figure 5 As shown, the push pedal module includes a push pedal bracket 130 and a base 131 fixedly connected with the push pedal bracket, a push pedal sliding plate 136, two push pedal hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com