A column welding device

A welding device and column technology, applied in welding equipment, auxiliary equipment, auxiliary welding equipment, etc., can solve the problems of potential safety hazards, low efficiency, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

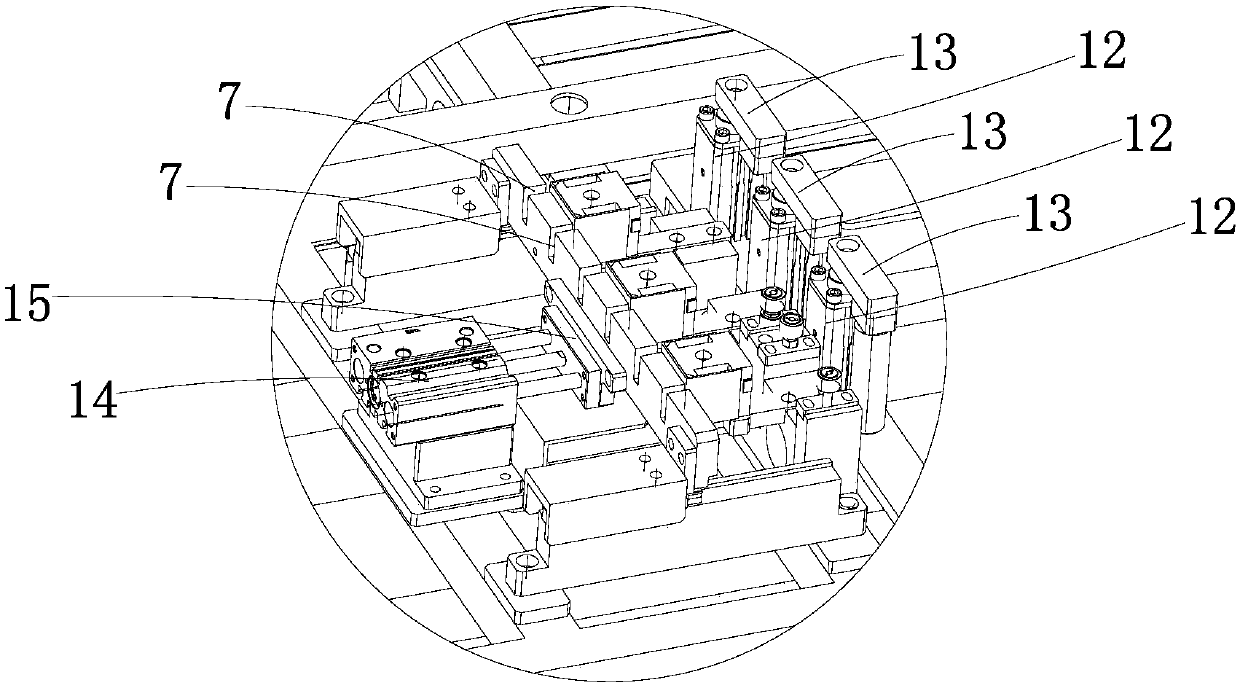

[0022] The substantive features of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

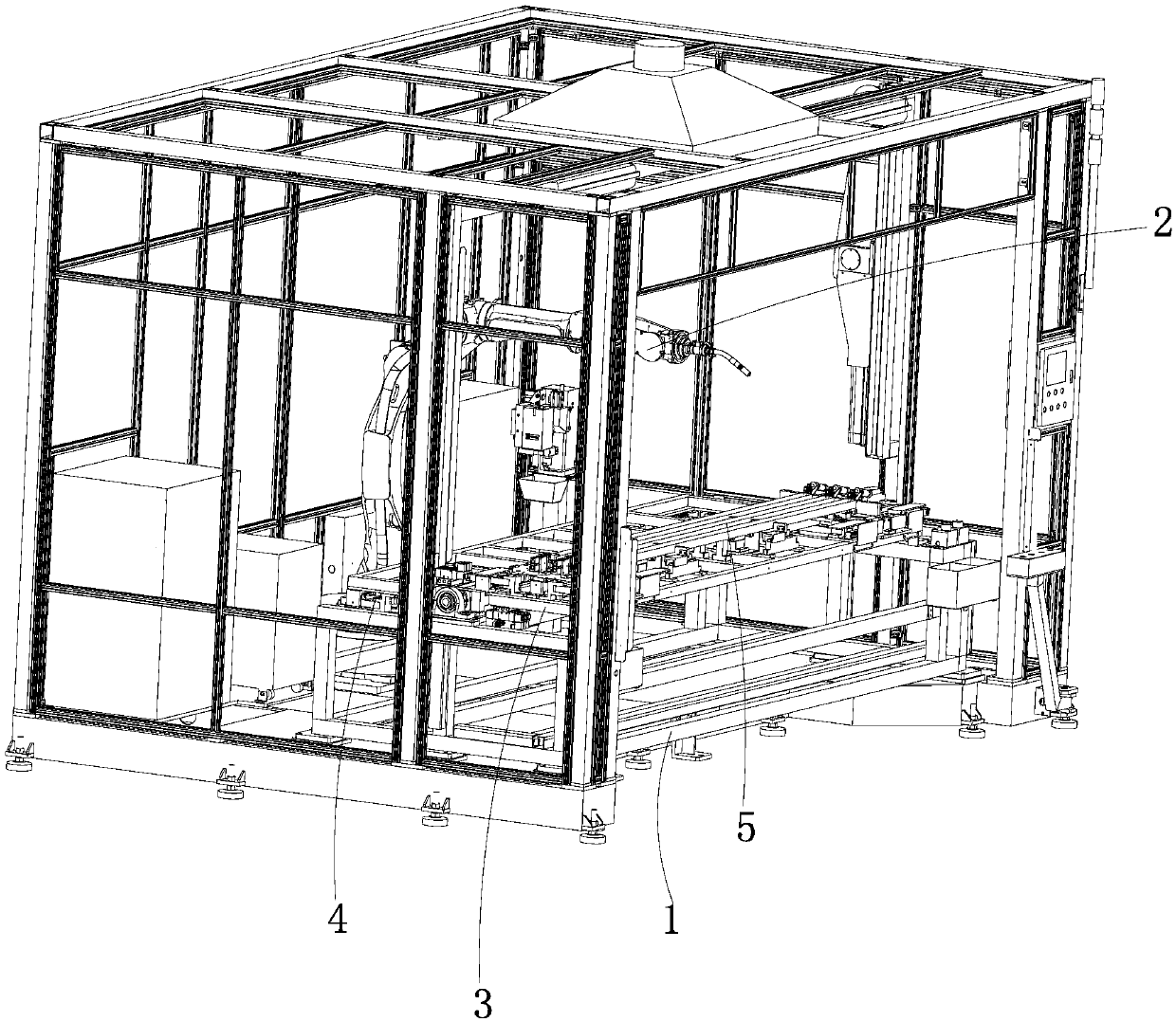

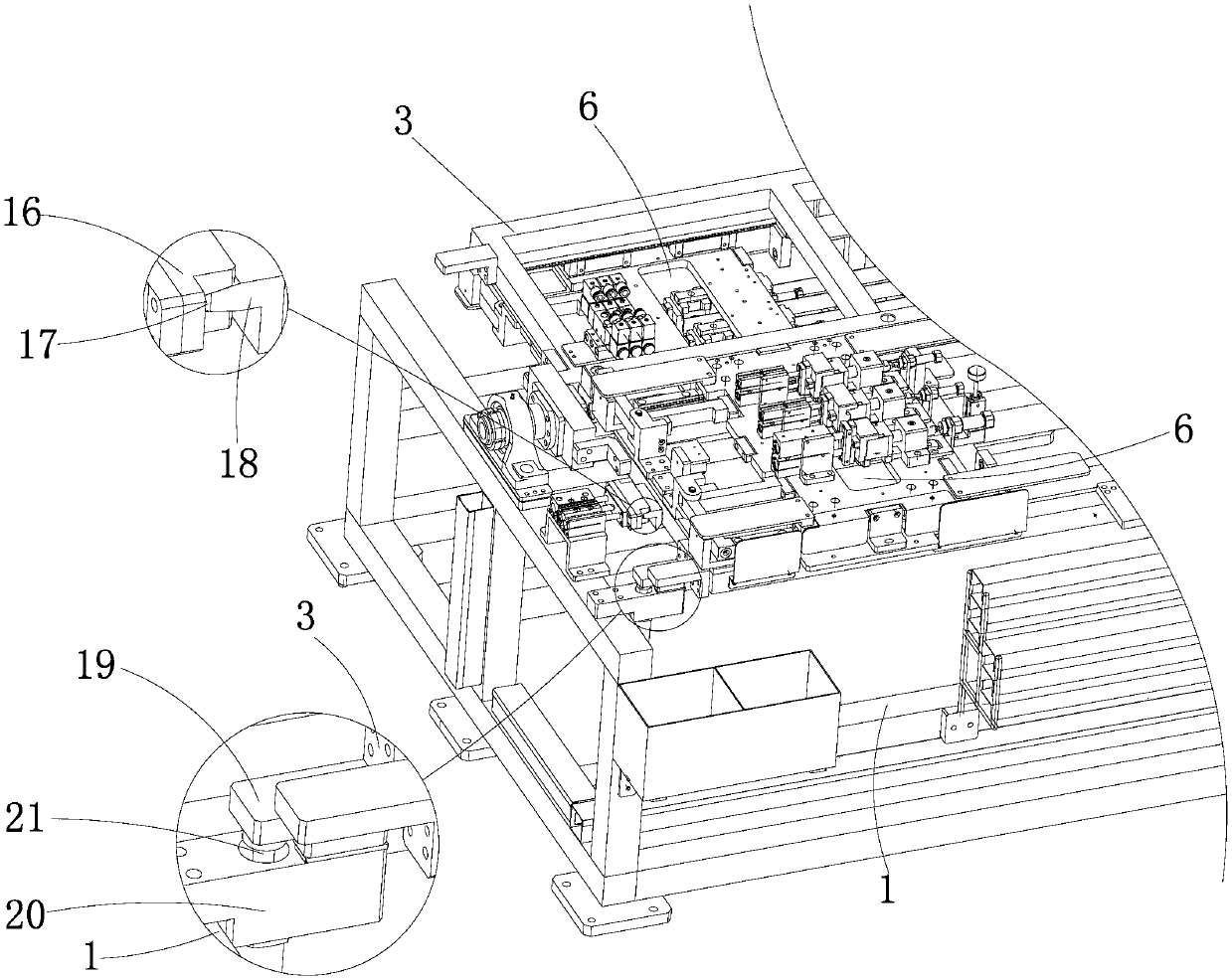

[0023] Such as figure 1 A column welding device shown is composed of a frame 1 and an operating arm 2 arranged on one side of the frame 1 for welding. The top of the frame 1 is rotatably connected to a turning frame 3, and on the turning frame 3 There are two sets of clamping structures arranged symmetrically with the rotation axis of the overturning frame 3, and the reciprocating rotation of the overturning frame 3 makes the two sets of clamping structures in the welding station 4 that cooperates with the operating arm 2 and the material replacement station of the opening and closing clamping structure. 5 switch between.

[0024] Two sets of clamping structures are arranged in an axisymmetric manner on the reciprocating turning frame 3, so that when one set of clamping structures is welded with the operation arm 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com