Milk replacer for eliminating allotriophagia of calves and producing white flesh of calves and preparation method thereof

A milk replacer, calf technology, applied in the application, animal feed, animal feed and other directions, can solve the problems of low product quality, low competitiveness, high feeding cost, reduce production performance, promote development and perfection, nutritional value high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

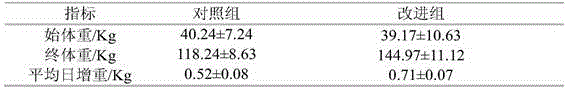

Embodiment 1

[0047] (1) The weight ratio of milk replacer is as follows (calculated by weight percentage):

[0048] Corn 35%, soybean meal 34%, flour 10%, vegetable oil 8%, milk powder 9%, salt 0.6%, soda 1%, calcium carbonate powder (50 mesh) 0.7%, amylase (2000u / g) 0.7%, premixed Material 1%.

[0049] Wherein, the component of premix comprises (by weight percentage):

[0050] Manganese Sulfate 4.00%, Sodium Selenite 0.50%, Yeast Selenium 2.50%, Chromium Picolinate 0.33%, Manganese Glycinate 6.05%, Zinc Glycinate 4.50%, Copper Glycinate 1.43%, Vitamin A 0.08%, Vitamin E 0.28% , vitamin D 3 0.02%, niacin 0.11%, rice husk powder (20 mesh) 40.00%, vitamin C 0.20%, chitosan 40.00%.

[0051] (2) Mix other main ingredients except vegetable oil and amylase with water, the mass ratio of the two is 1:8, stir evenly, add vegetable oil after soaking for 80 minutes. Steam heating is used for cooking. When the pressure of the steam heater reaches 4atm, start heating, stir while heating, stop stirr...

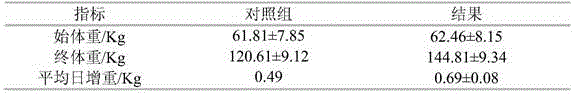

Embodiment 2

[0057] (1) The weight ratio of milk replacer is as follows (calculated by weight percentage):

[0058] Corn 45%, soybean meal 26%, flour 16%, vegetable oil 4%, milk powder 4%, salt 1.2%, soda 0.4%, calcium carbonate powder (50 mesh) 1.2%, amylase (3000u / g) 1.2%, premixed Material 1%.

[0059] Wherein, the component of premix comprises (by weight percentage):

[0060] Manganese Sulfate 3.22%, Sodium Selenite 0.30%, Yeast Selenium 2.10%, Chromium Picolinate 0.20%, Manganese Glycinate 4.30%, Zinc Glycinate 4.10%, Copper Glycinate 1.20%, Vitamin A 0.05%, Vitamin E 0.20% , vitamin D 3 0.03%, niacin 0.20%, rice husk powder (20 mesh) 37.00%, vitamin C 0.10%, chitosan 47.00%.

[0061] (2) Mix other main ingredients except vegetable oil and amylase with water, the mass ratio of the two is 1:8, stir evenly, add vegetable oil after soaking for 100min. Steam heating is used for cooking. When the pressure of the steam heater reaches 4atm, start heating, stir while heating, stop stirrin...

Embodiment 3

[0067] (1) The weight ratio of milk replacer is as follows (calculated by weight percentage):

[0068] Corn 40%, soybean meal 30%, flour 16%, vegetable oil 4.4%, milk powder 5%, salt 1%, soda 0.8%, calcium carbonate powder (50 mesh) 0.8%, amylase (4000u / g) 1%, premixed Material 1%.

[0069] Wherein, the component of premix comprises (by weight percentage):

[0070] Manganese Sulfate 3.61%, Sodium Selenite 0.40%, Yeast Selenium 2.30%, Chromium Picolinate 0.27%, Manganese Glycinate 5.18%, Zinc Glycinate 4.30%, Copper Glycinate 1.32%, Vitamin A 0.07%, Vitamin E 0.24% , vitamin D 3 0.03%, niacin 0.16%, rice husk powder (20 mesh) 38.50%, vitamin C 0.15%, chitosan 43.50%.

[0071] (2) Mix other main ingredients except vegetable oil and amylase with water, the mass ratio of the two is 1:6, stir evenly, soak for 120min, then add vegetable oil. Steam heating is used for cooking. When the pressure of the steam heater reaches 4 atm, start heating, stir while heating, stop stirring wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com