Method for preparing near-zero thermal expansion ZrO2/ZrW2O8 composite material

A composite material, near-zero expansion technology, applied in the direction of manufacturing tools, auxiliary molding equipment, ceramic molding machines, etc., can solve the problems of uneven product performance, long composite material cycle, low efficiency, etc., to shorten the preparation cycle, sample Effects of performance improvement and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

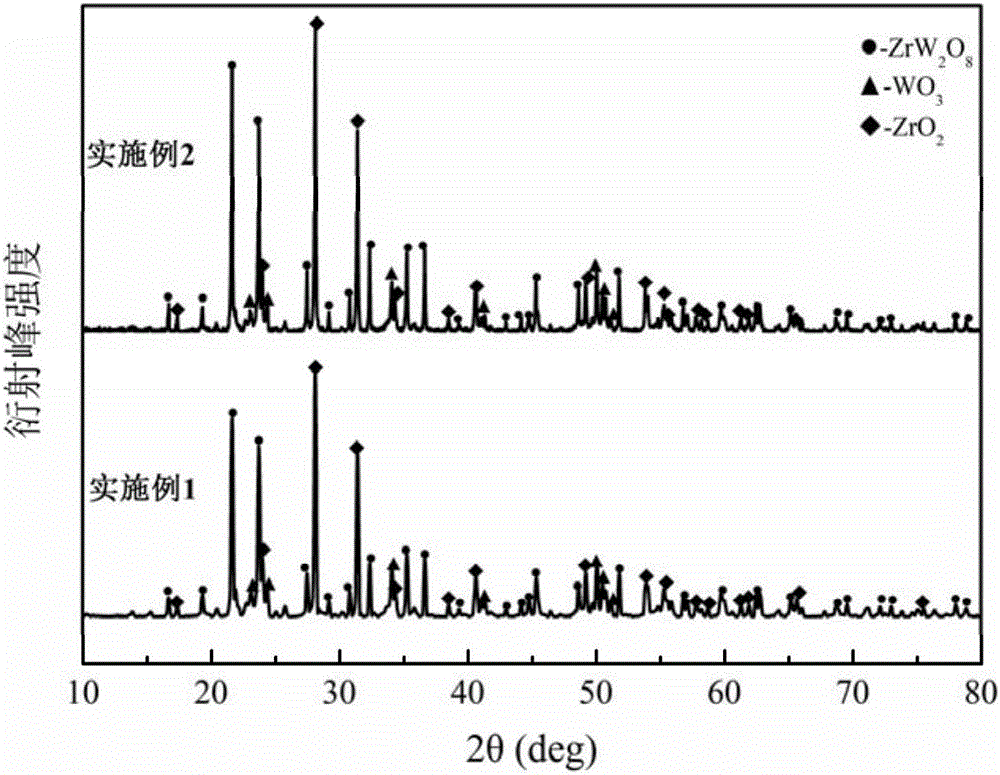

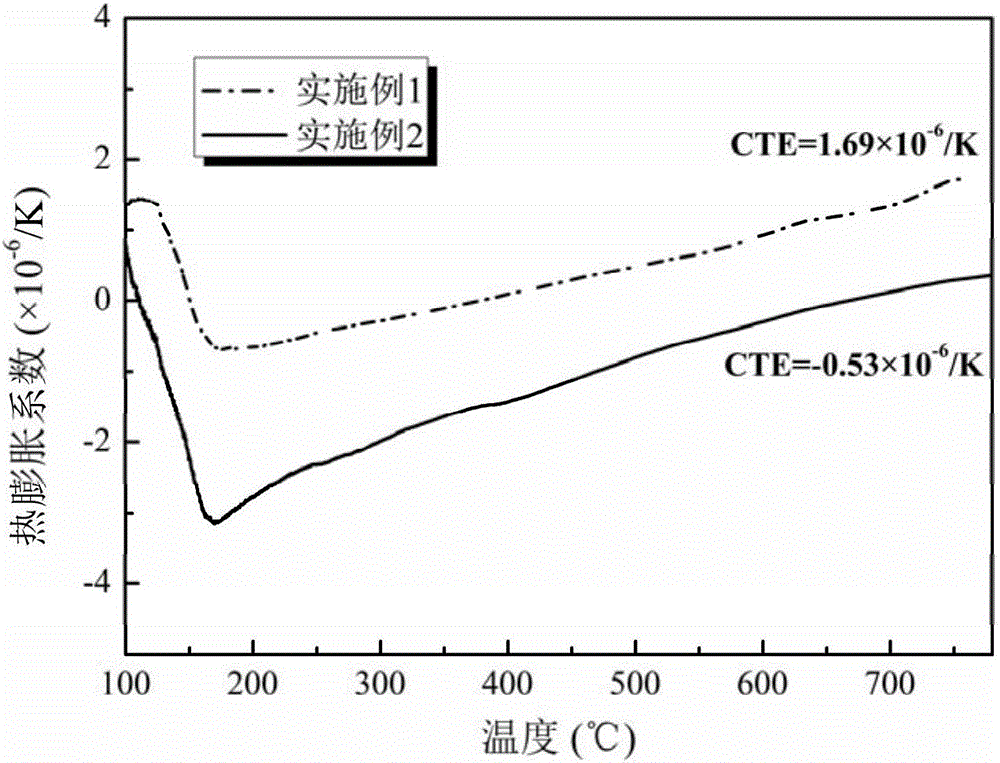

Embodiment 1

[0040] A preparation of near-zero expansion ZrO 2 / ZrW 2 o 8 The composite material method is carried out in the following steps:

[0041] 1. Ingredients: weigh nano-ZrO respectively 2 Powder 9g, high purity ZrW 2 o 8 Powder 6g, mixed together;

[0042] 2. Wet ball milling: Add the mixed powder in step 1 together with 60g of zirconia grinding media and 10.5g of distilled water into the ball mill tank, and use a fast ball mill to mill for 50 minutes until the average particle size of the mixed powder slurry is D 50 ≤0.9μm, then add 1.2g of polyvinyl alcohol binder with a concentration of 5%, and take out the slurry after ball milling for 5 minutes;

[0043] 3. Manual granulation: sieve and dry the slurry taken out in step 2, crush it in a mortar, spray and add 0.3g of water to humidify the powder, then pass through a 60-mesh standard sieve three times, and package and stale for 2 days;

[0044] 4. Dry pressing molding: put the sample obtained in step 3 into a Φ8×20 (unit...

Embodiment 2

[0051] A preparation of near-zero expansion ZrO 2 / ZrW 2 o 8 The composite material method is carried out in the following steps:

[0052] 1. Ingredients: weigh nano-ZrO respectively 2 Powder 8.48g, high purity ZrW 2 o 8 Powder 6.52g, mixed together;

[0053] 2. Wet ball milling: Add the mixed powder in step 1 together with 60g of zirconia grinding media and 10.5g of distilled water into the ball mill tank, and use a fast ball mill to mill for 50 minutes until the average particle size of the mixed powder slurry is D 50 ≤0.9μm, then add 1.2g of polyvinyl alcohol binder with a concentration of 5%, and take out the slurry after ball milling for 5 minutes;

[0054] 3. Manual granulation: sieve and dry the slurry taken out in step 2, crush it in a mortar, spray and add 0.3g of water to humidify the powder, then pass through a 60-mesh standard sieve three times, and package and stale for 2 days;

[0055] 4. Dry pressing molding: put the sample obtained in step 3 into a Φ8×20...

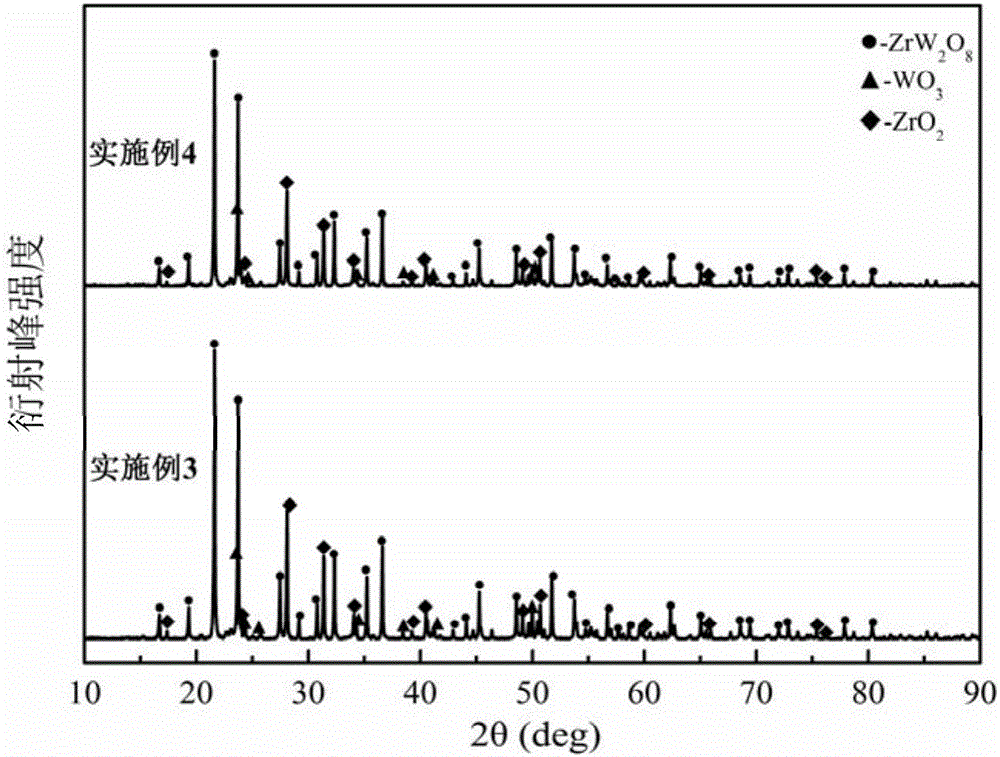

Embodiment 3

[0062] A preparation of near-zero expansion ZrO 2 / ZrW 2 o 8 The composite material method is carried out in the following steps:

[0063] 1. Ingredients: weigh nano-ZrO respectively 2 Powder 7.23g, high purity WO 3 Powder 7.77g, mixed together;

[0064] 2. Wet ball milling: Add the mixed powder in step 1 together with 60g of zirconia grinding media and 11g of distilled water into the ball mill tank, and use a fast ball mill to mill for 50 minutes until the average particle size of the mixed powder slurry is D 50 ≤0.9μm, then add 1.2g of polyvinyl alcohol binder with a concentration of 5%, and take out the slurry after ball milling for 5 minutes;

[0065] 3. Manual granulation: sieve and dry the slurry taken out in step 2, spray and add 0.3g of water to humidify the powder after crushing in a mortar, then sieve (60 mesh standard sieve) three times, and package and stale for 2 days;

[0066] 4. Dry pressing molding: put the sample obtained in step 3 into a Φ8×20 mold, pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com