Flexible Strip Winder

A winding machine and strip technology, applied in the direction of winding strips, thin material processing, transportation and packaging, etc., can solve the problems of automatic withdrawal, increased transportation costs, increased labor costs, etc., to achieve rich profit returns, structure Compact, money-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

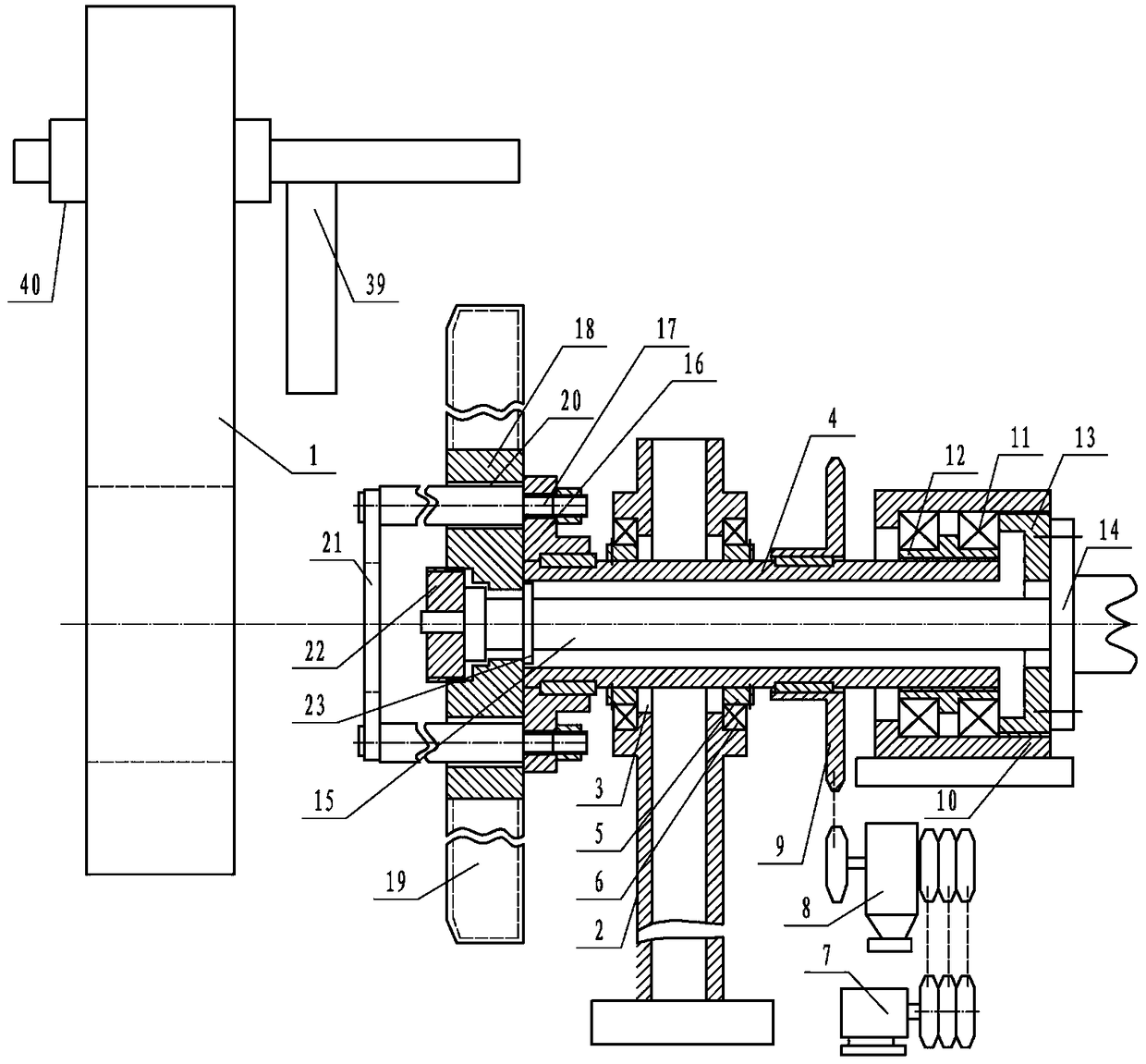

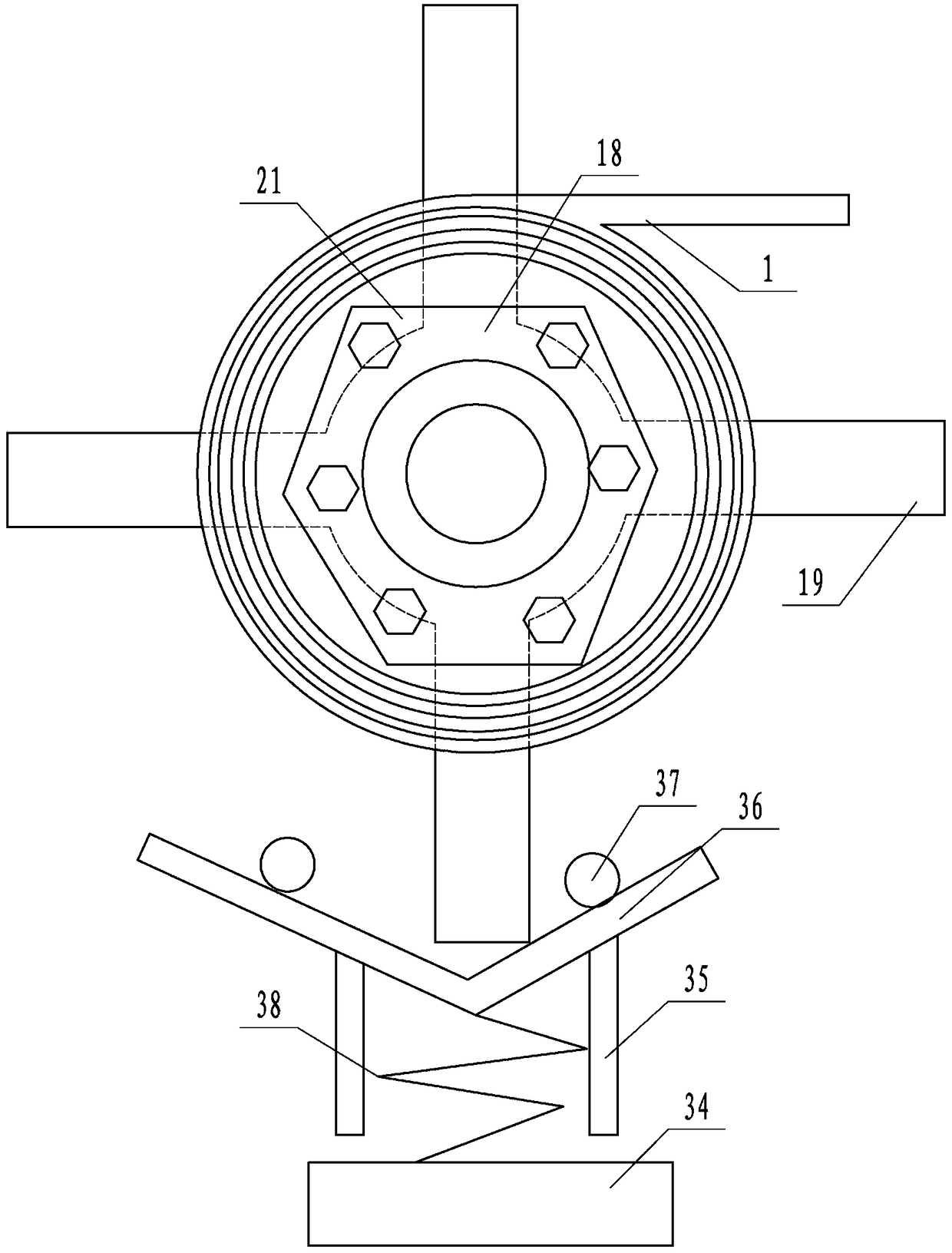

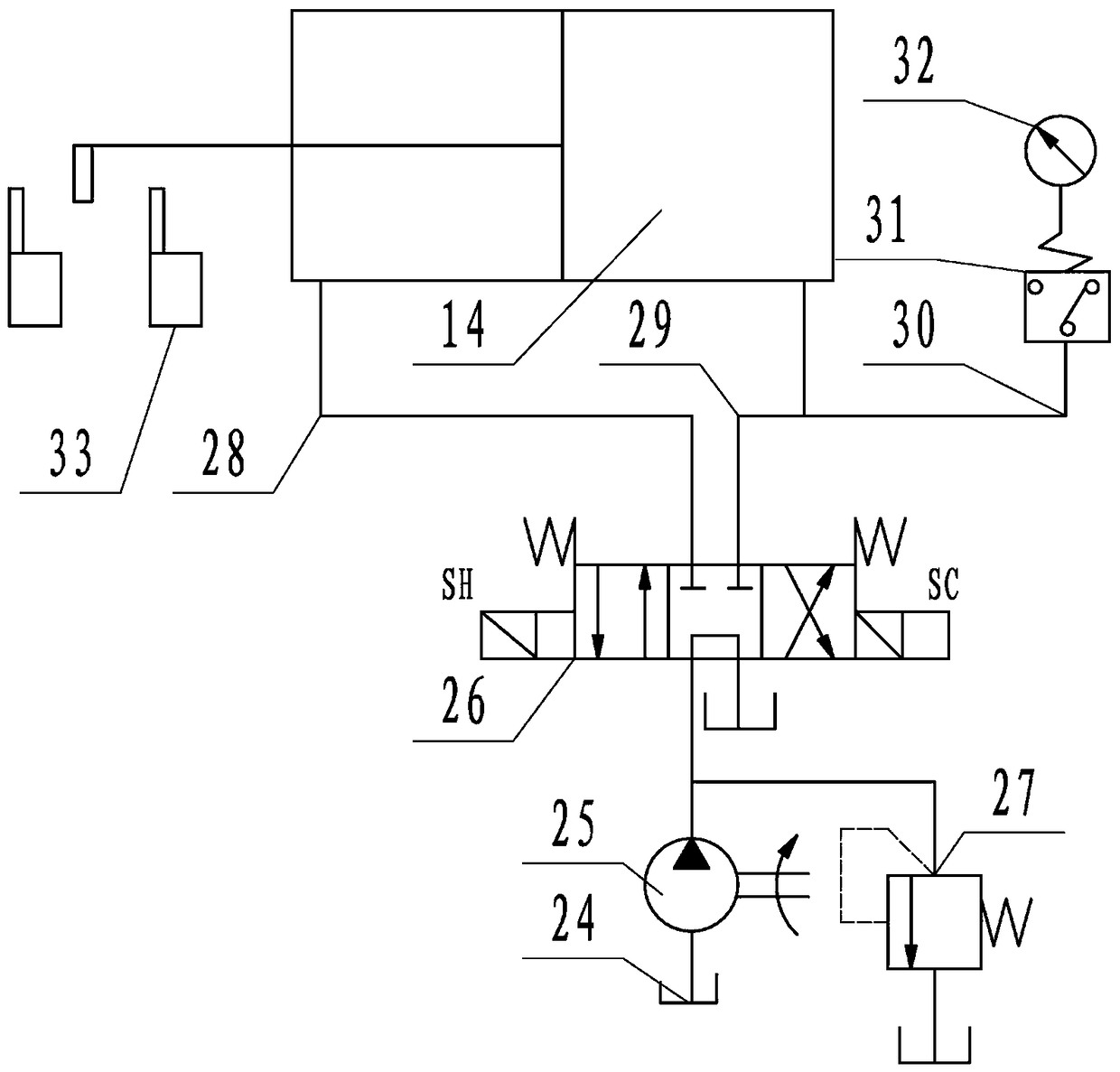

[0028] like Figure 1-4 As shown, the flexible strip winding machine of this embodiment includes a support frame 2, a mandrel rotating device arranged on the support frame 2, and a core removal device arranged on the support frame 2;

[0029] Along the direction of the mandrel, the stripping unit pushes the rubber / plastic strip roll 1 reeled on the mandrel of the mandrel turning unit out of the mandrel or the stripping unit pushes the mandrel of the mandrel turning unit from the rubber / plastic strip Pull out the core from the inner hole of volume 1. This application can be applied to other similar strip windings.

[0030] The mandrel is a cylindrical structure, a conical structure, a pyramidal structure, a prismatic structure or is composed of at least two rods or is provided between the mandrel and the inner hole of the rubber / plastic strip roll 1 for passing through the bundled rubber / plastic strip roll 1 Gap in the rope. This facilitates threading.

[0031] Specifically...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com