Insulated and pressure-preserved sample sampling device

A sampling device, the original technology, applied in the direction of sampling device, sampling, measuring device, etc., can solve the problems of increasing the oxygen content of the medium, changing the composition of the medium, corrosion mechanism, corrosion morphology, reducing the pH value of the medium, etc., to ensure accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

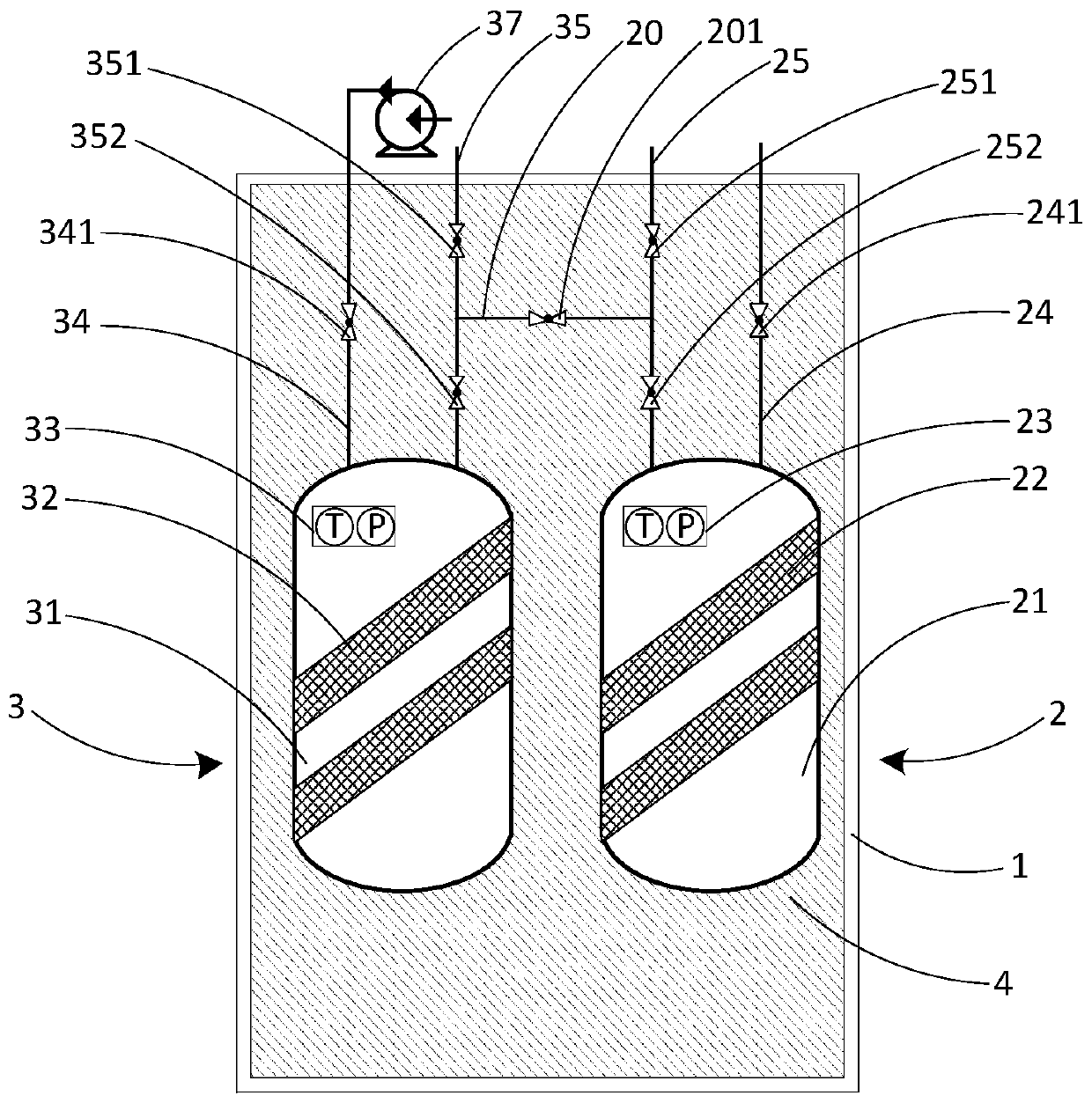

[0022] Such as figure 1 As shown, it is a heat preservation and pressure maintaining sample sampling device of the present invention, which includes a box body 1, a raw liquid assembly 2 and a raw gas assembly 3 arranged in the box body 1, and an insulating layer 4 filled in the box body 1, and the stock solution assembly 2 and the original gas assembly 3 are wrapped by the insulation layer 4. The raw liquid component 2 can realize the collection of liquid samples and keep the internal pressure and temperature the same as the sampling environment; the raw gas component 3 can realize the collection of gas samples and keep the internal pressure and temperature the same as the sampling environment.

[0023] In this embodiment, the stock solution assembly 2 includes: a stock solution tank 21 for holding liquid samples; a stock solution heating element 22 for heating the stock solution tank 21 to ensure that the temperature in the stock solution tank 21 is always the same as the te...

Embodiment 2

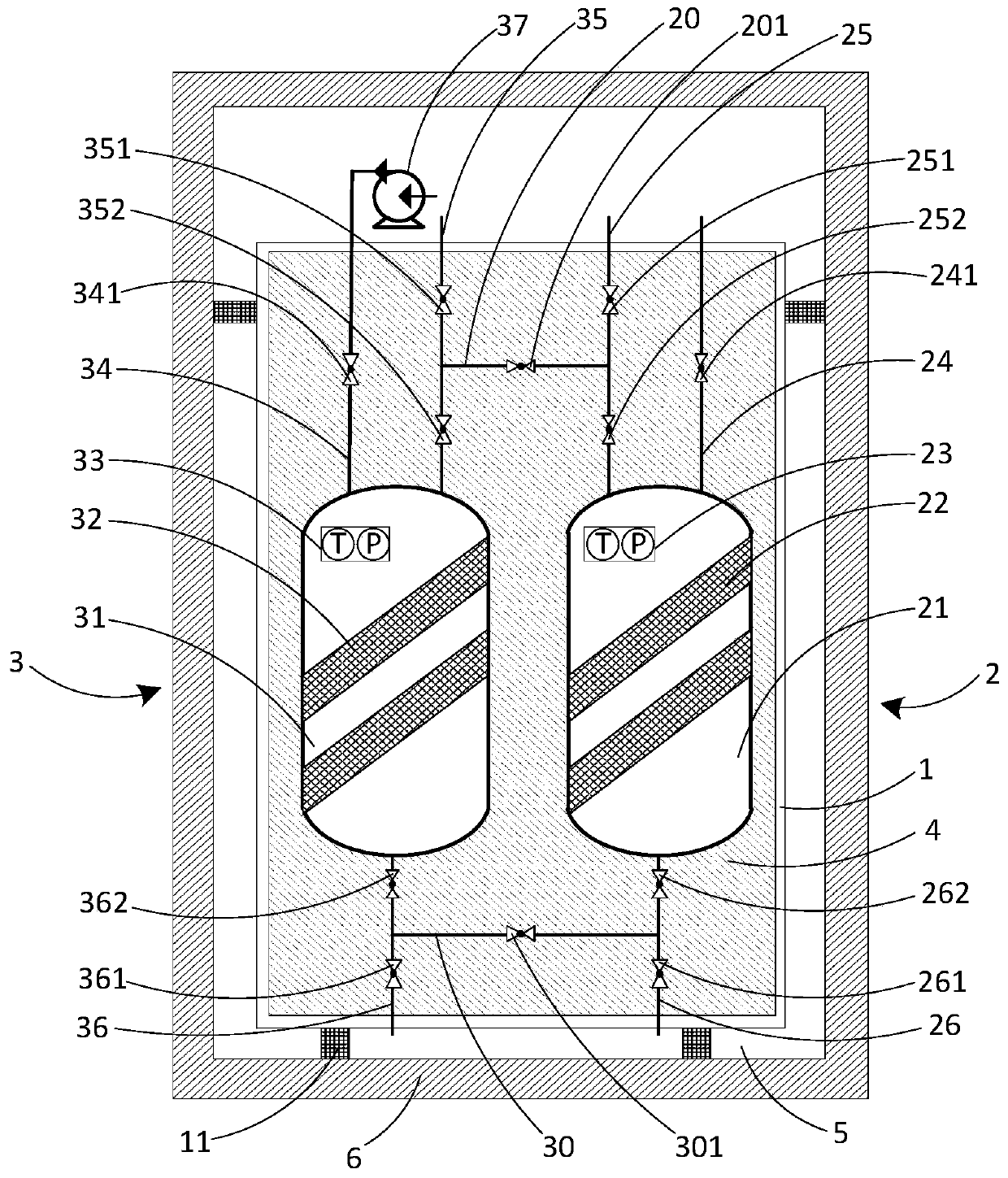

[0039] Such as figure 2 As shown, different from Example 1, the heat preservation and pressure keeping sample sampling device in this embodiment also includes an inner shell 5 and an outer shell 6, and the box body 1 is accommodated in the inner shell 5, and the side wall of the inner shell 5 is recessed The fixing groove, the casing 1 is provided with a fixing column 11 matching the fixing groove, the inner casing 5 is accommodated in the outer casing 6, and the inner casing 5 is used to fix the casing 1, and the outer casing 6 is in contact with the outside, and mainly plays a protective role.

[0040] In this embodiment, the raw liquid assembly 2 further includes a third raw liquid pipe 26, one end of the third raw liquid pipe 26 communicates with the raw liquid tank 21, and the other end extends to the outside of the box body 1, and the third raw liquid pipe 26 is provided with a first liquid outlet valve 261; the raw gas assembly 3 also includes a third raw gas pipe 36, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com