Integrated device for in-situ static and dynamic force calibration

A static and dynamic, in-situ technology, applied in the direction of measuring devices, force/torque/power measuring instrument calibration/testing, instruments, etc., it can solve the problem that the direction and force point are difficult to keep consistent, the effective frequency band is narrow, and the force value of the excitation is small and other problems, to achieve the effect of compact structure, short falling edge time, and adjustable force value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

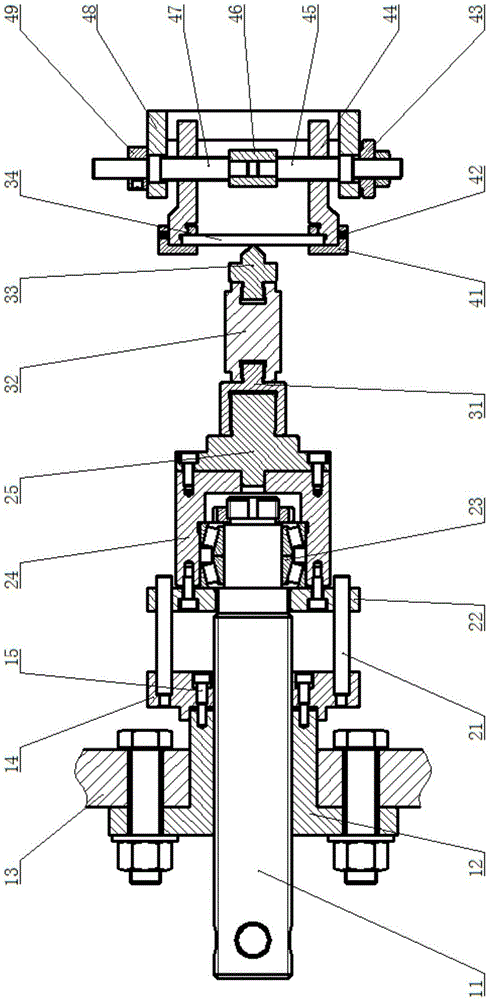

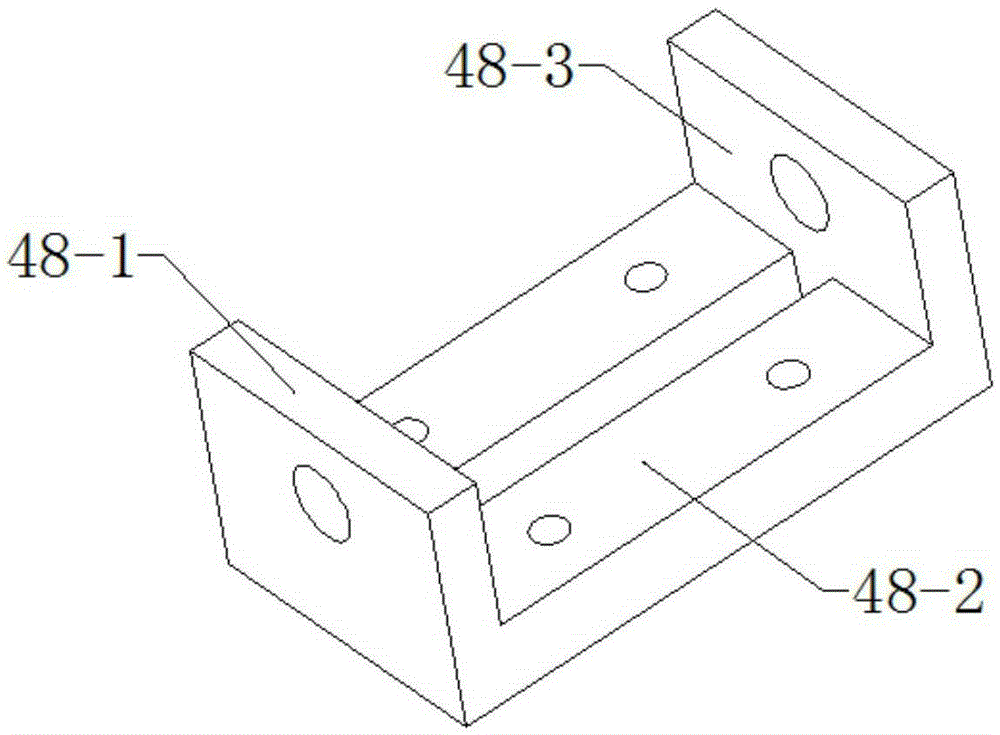

[0038] combine Figure 1~Figure 4 , the integrated device for in-situ static and dynamic calibration includes a loading mechanism, a direction control mechanism, a force source control mechanism and a centering clamping mechanism. One end of the direction control mechanism is fixedly connected with the loading mechanism, the other end is threadedly connected with one end of the force source control mechanism, and the centering clamping mechanism is connected with the other end of the force source control mechanism. The other end of the centering clamping mechanism is fixedly connected with the interface part of the system to be marked.

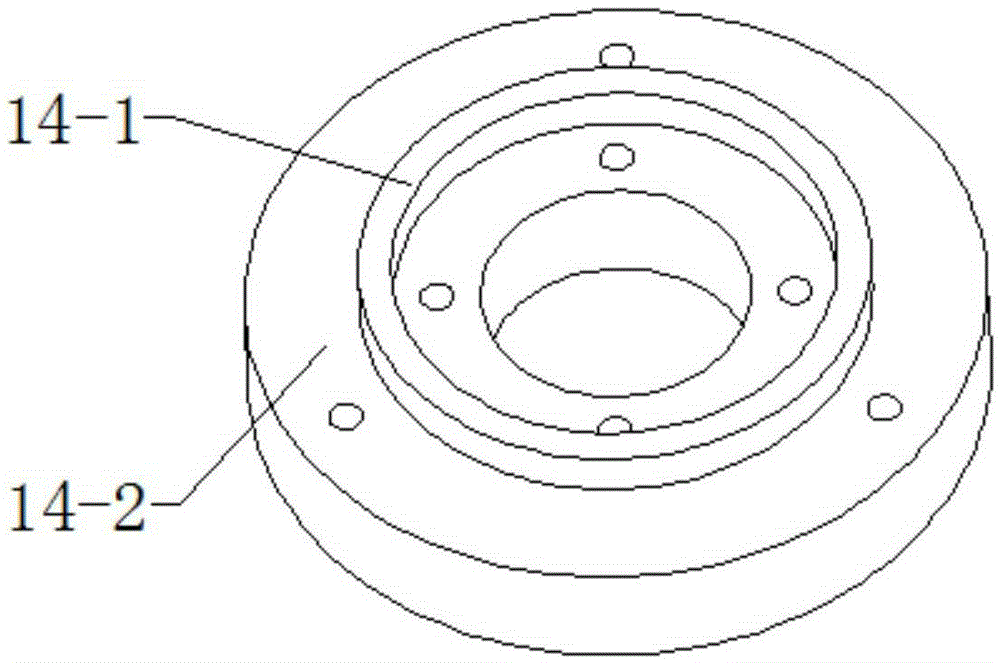

[0039] combine figure 1 and figure 2 , the loading mechanism 1 includes a lead screw 11 , a flange nut 12 , a mounting plate 13 , an anti-backlash nut 14 and an anti-backlash screw 15 . The center of the mounting plate 13 is provided with a first through hole through which the lead screw 11 passes and is connected with the direction contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com