A drying device with a selective drying rack

The technology of drying equipment and drying rack is applied in the directions of drying, drying machine, lighting and heating equipment, etc., which can solve the problems of troublesome operation, high cost, low drying efficiency, etc., and achieve the effect of reducing waiting time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Combine below Figure 1-5 The present invention will be described in detail.

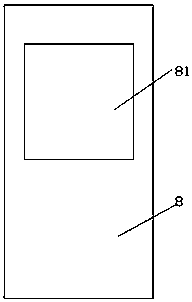

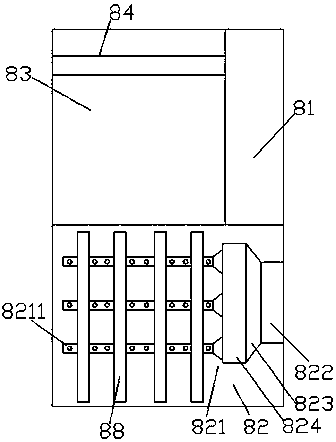

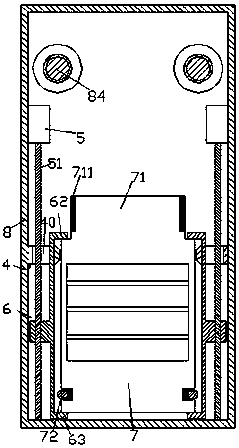

[0012] According to an embodiment of the present invention, a drying device with a selective drying rack includes a base body 8, wherein the inner space of the base body 8 includes a bottom for accommodating multiple drying rack assemblies 88 and drying equipment 821 The drying area 82 of the upper part, the operating area 81 for operating the selected drying rack on the upper front side, and the drying rack sliding path area 83 on the upper rear side, the drying rack sliding path area 83 is provided with front and rear direction The extended sliding drive assembly 84 is used to make the selected drying rack slide in the front and back direction; wherein, each of the plurality of drying rack assemblies 88 includes a drying rack mounting plate 7 and is located on the drying rack mounting plate 7. The lifting drive screw 51 on both sides of the plate 7 and the lifting frame 6 driven by the lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com