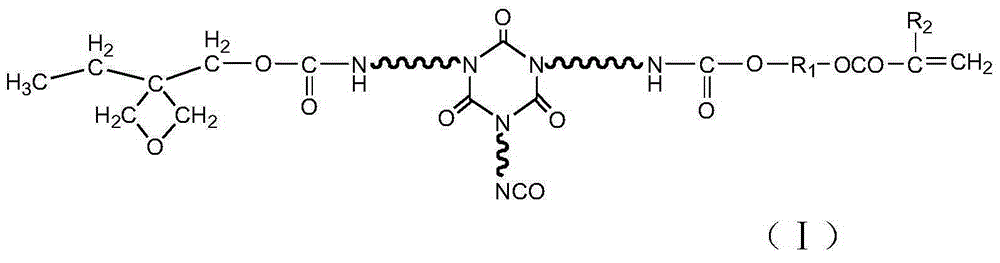

Multi-cured optical resin and synthesizing method thereof

A multi-curing, optical resin technology, used in organic chemistry, non-polymer organic compound adhesives, adhesives, etc., can solve the problems of LOCA not curing, incomplete curing, and unable to absorb UV light, and achieve good application value , The effect of low production cost and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

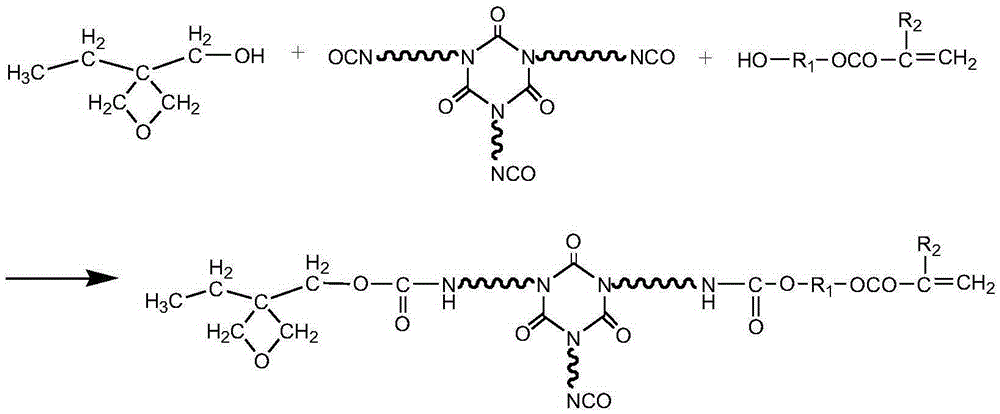

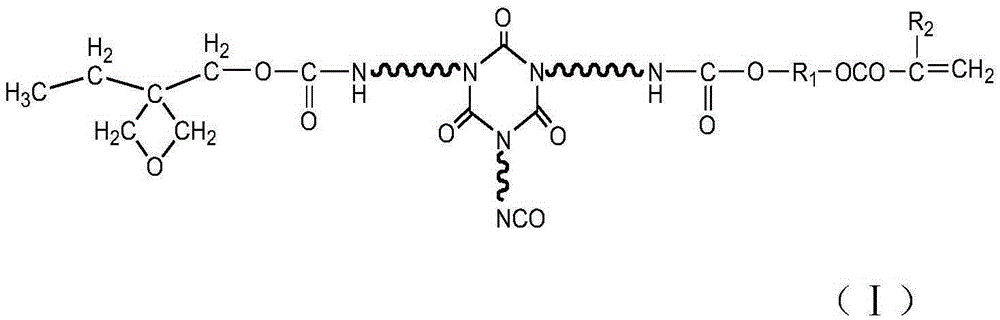

Method used

Image

Examples

Embodiment 1

[0027] HDI trimer (Bayer company, desmodur N3300) 80g, 3-ethyl-3-oxetanemethanol 10g, hydroxyethyl acrylate 4g, polymerization inhibitor p-hydroxyanisole 0.1g, catalyst dilauric acid di Add 0.01 g of butyltin into a three-necked flask with a thermometer, raise the temperature to 65 degrees, control the temperature at 75 degrees, and react for 2 hours. The NCO group is analyzed by an infrared spectrometer, and when the NCO peak does not change, the heating reaction is stopped to obtain a multi-curable optical resin.

Embodiment 2

[0029] HDI trimer (Bayer company, desmodur N3300) 110g, 3-ethyl-3-oxetanemethanol 5g, hydroxyethyl methacrylate 10g, polymerization inhibitor p-hydroxyanisole 0.1g, catalyst dilaurel Add 0.01 g of dibutyltin dibutyltin into a three-necked flask with a thermometer, raise the temperature to 65 degrees, control the temperature at 70 degrees, and react for 3 hours. The NCO group is analyzed by an infrared spectrometer, and when the NCO peak does not change, the heating reaction is stopped to obtain a multi-curable optical resin.

Embodiment 3

[0031] HDI trimer (Bayer, desmodur N3300) 100g, 3-ethyl-3-oxetanemethanol 8g, hydroxypropyl acrylate 6g, polymerization inhibitor p-hydroxyanisole 0.1g, catalyst dilauric acid di Add 0.01 g of butyltin into a three-necked flask with a thermometer, raise the temperature to 65 degrees, control the temperature at 73 degrees, and react for 2 hours. The NCO group is analyzed by an infrared spectrometer, and when the NCO peak does not change, the heating reaction is stopped to obtain a multi-curable optical resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com