Constant-temperature fertilizer mixing tank

A technology for mixing tanks and fertilizers, applied in mixers, mixers with rotating stirring devices, dissolving, etc., can solve time-consuming and labor-intensive problems, achieve the effects of reducing labor intensity, increasing mixing speed, and saving time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

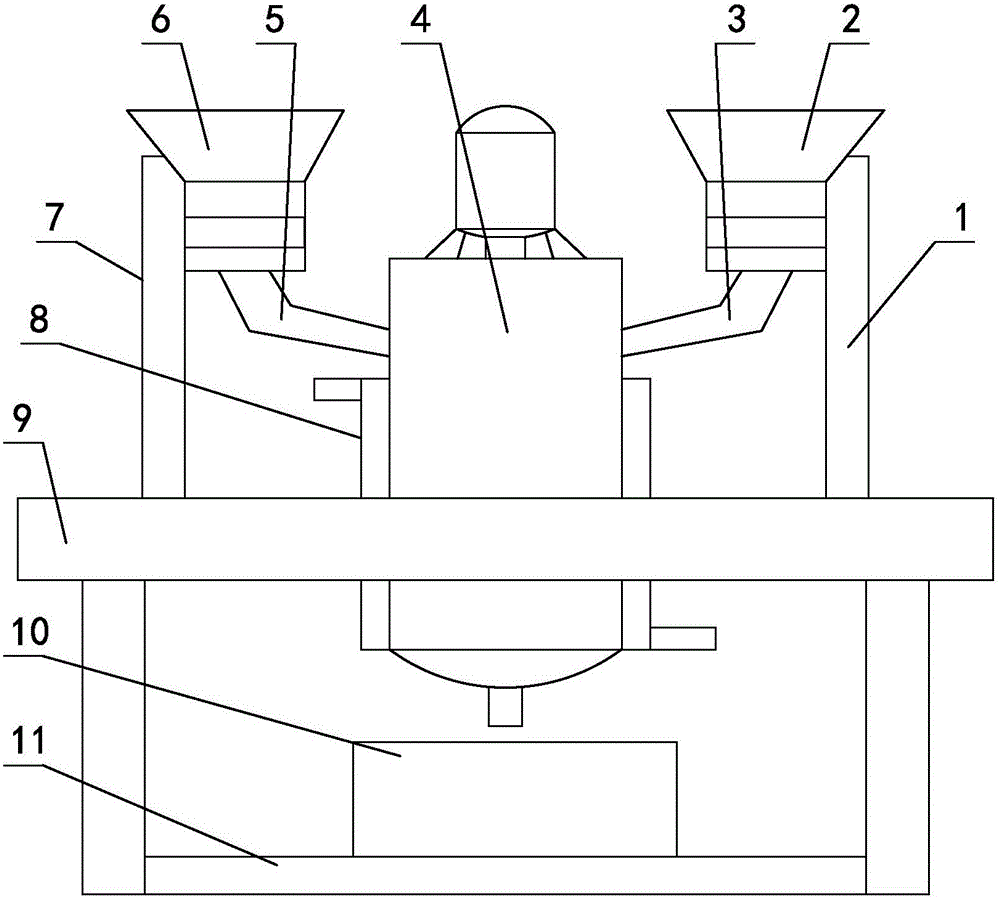

[0017] As shown in 1, the thermostatic fertilizer mixing tank includes a mixing tank 4 equipped with a stirrer and a workbench 9. The mixing tank 4 is vertically installed on the workbench 9, and the bottom of the mixing tank 4 is provided with a discharge port. A first support frame 1 and a second support frame 7 are vertically arranged on the workbenches 9 on the left and right sides of the tank 4, respectively. A first feeding trough 2 is installed on the first support frame 1, and the first feeding trough 2 passes through The first feed line 3 is connected to the top of the mixing tank 4, and a second feed tank 6 is installed on the second support frame 7, and the second feed tank 6 is connected to the top of the mixing tank 4 through the second feed line 5 , The product collection tank 10 is set directly below the discharge port at the bottom of the mixing tank 4, the product collection tank 10 is placed on the placing plate 11, the placing plate 11 is fixed at the lower pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com