A friction plate for a fluid-viscous clutch and a processing method thereof

A friction plate and clutch technology, applied in the field of fluid-viscous clutches, can solve the problems of reducing the difference between theoretical transmission torque and actual transmission torque, increasing torque, reducing oil film coverage, etc., and achieving an increase in effective area , the effect of increasing the transmitted torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

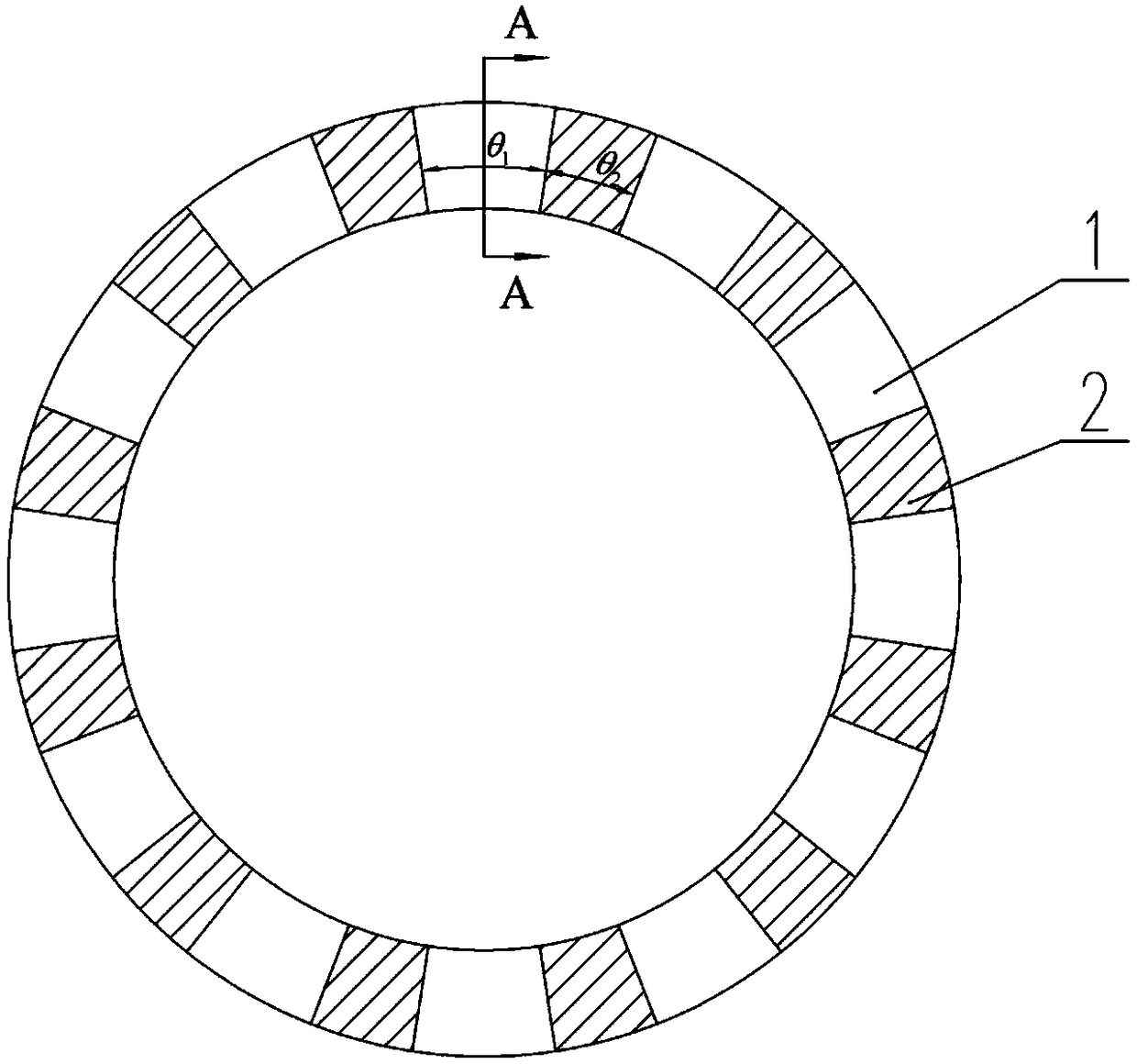

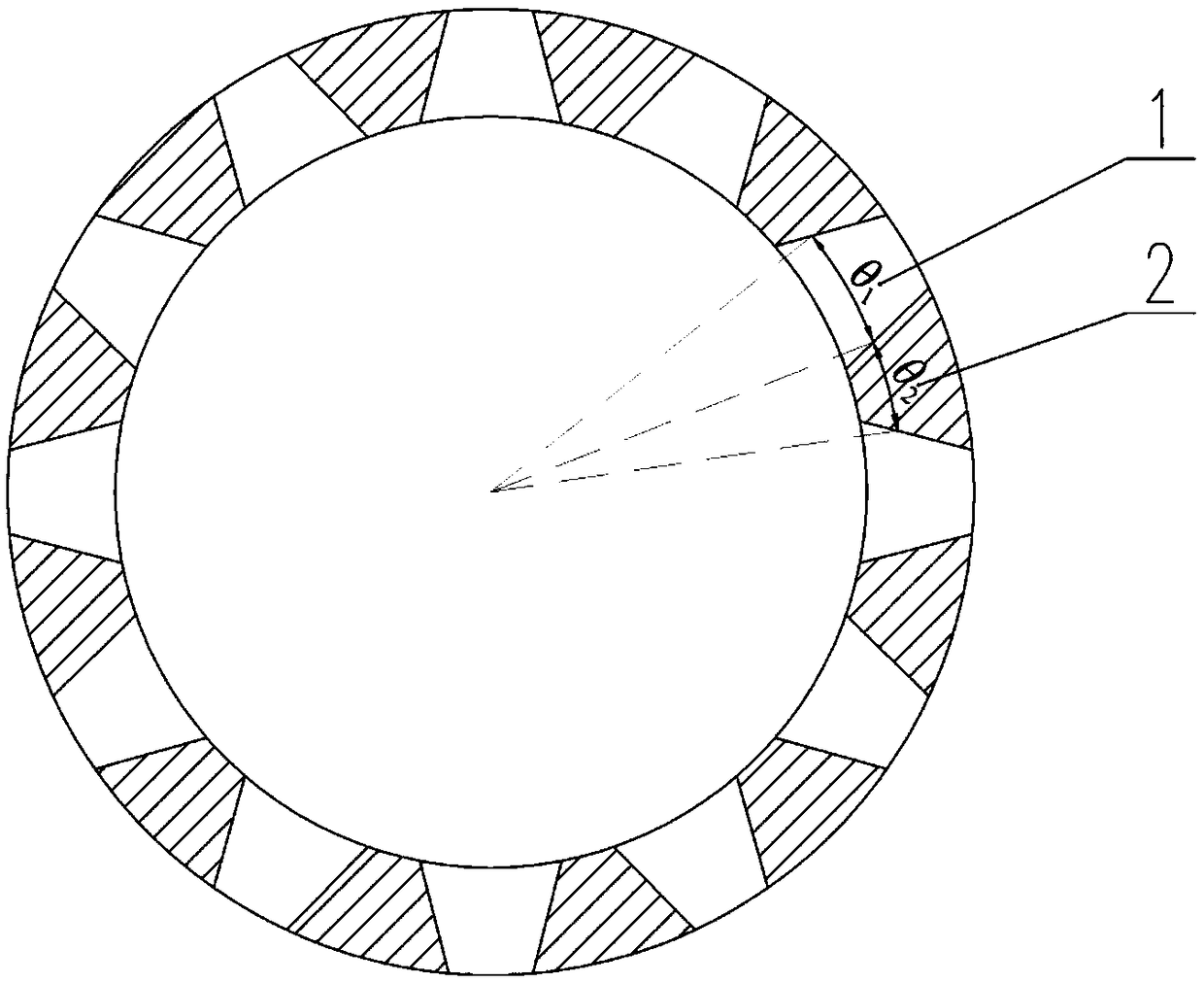

[0031] figure 2 Shown is a schematic diagram of changing the angle of the oil groove area. In the figure, the surface of the friction plate includes the changed oil groove area 1 and the non-oil groove area 2. One of the friction plate processing methods changes the oil passing capacity by changing the angle of the oil groove area. The angle of the oil groove area The bigger it is, the stronger the oil passing ability of the oil groove is, otherwise the weaker the oil passing ability is. During processing, the angle of the oil groove area decreases with the increase of the radius, that is, the angle of the oil groove at the smallest inner diameter is the largest, and the angle of the oil groove at the largest outer diameter is the smallest, so that the oil passing ability at the inner diameter is stronger and the oil passing ability at the outer diameter is weaker. , so as to forcibly increase the oil groove coverage of the outer ring.

Embodiment 2

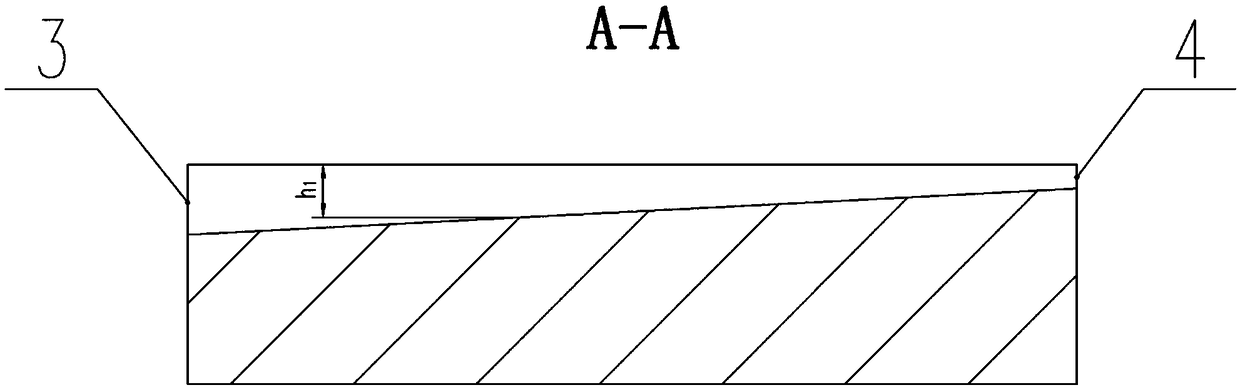

[0033] image 3 Shown is a radial cross-sectional view of changing the depth of the oil groove. In the figure, the depth of the oil inlet 3 and the oil outlet 4 are different. One of the friction plate processing methods changes the oil passing capacity by changing the depth of the oil groove. The greater the depth of the oil groove, the greater the The stronger the oil passing ability of the oil groove, the weaker the oil passing ability is vice versa. During processing, the depth of the oil groove decreases as the radius increases, that is, the depth of the oil groove at the smallest inner diameter is the largest, and the depth of the oil groove at the largest outer diameter is the smallest, so that the oil passing ability at the inner diameter is stronger and the oil passing ability at the outer diameter is weaker. Thus, the oil groove coverage of the outer ring is forcibly increased.

Embodiment 3

[0035] A method for processing the friction plate, changing the oil groove angle and oil groove depth at the same time to change the oil passing capacity, the larger the oil groove area angle, the stronger the oil passing capacity of the oil groove, and the larger the oil groove depth, the greater the oil passing capacity of the oil groove The stronger it is, on the contrary, the weaker the ability to pass oil. During processing, the angle of the oil groove area decreases with the increase of the radius, and the depth of the oil groove decreases with the increase of the radius, so that the oil passage capacity at the inner diameter is stronger and the oil passage capacity at the outer diameter is weaker, thereby compulsorily increasing Large outer ring oil groove coverage.

[0036] In the first embodiment, the second embodiment and the third embodiment, the oil passing capacity is changed by changing the parameters of the oil tank. In order to achieve 100% oil film coverage f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com