90-degree overturning airflow pneumatic conveying line

A technology of air flow and air delivery, which is applied in the field of 90° reverse air flow and air delivery line, which can solve the problems of large friction at the bottom of the tank, long production period, and high cost, and achieve the effects of short production period, low cost and reduced friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0018] The preferred embodiment of the 90° overturned air flow air delivery line of the present invention is:

[0019] It includes a blowing board, a U-shaped box and a fan. The U-shaped box is a cavity with an open upper end and a sealed lower end. There is a wind shield in the middle of the U-shaped box. The opening of the U-shaped box faces upwards. The blowing plate is installed at the opening of the U-shaped box so that the U-shaped box forms a pressurized cavity, the pressurized cavity is connected with the fan, and the surface of the blowing plate is opened along the conveying direction. There are a plurality of directional blowing ports, and the multiple directional blowing ports form an air channel flowing in the conveying direction, and the wind source provided by the fan creates pressure in the pressurized cavity to make the airflow flow out from the directional blowing ports in the conveying direction.

[0020] The U-shaped box includes an upper bellows U-shaped bo...

specific Embodiment

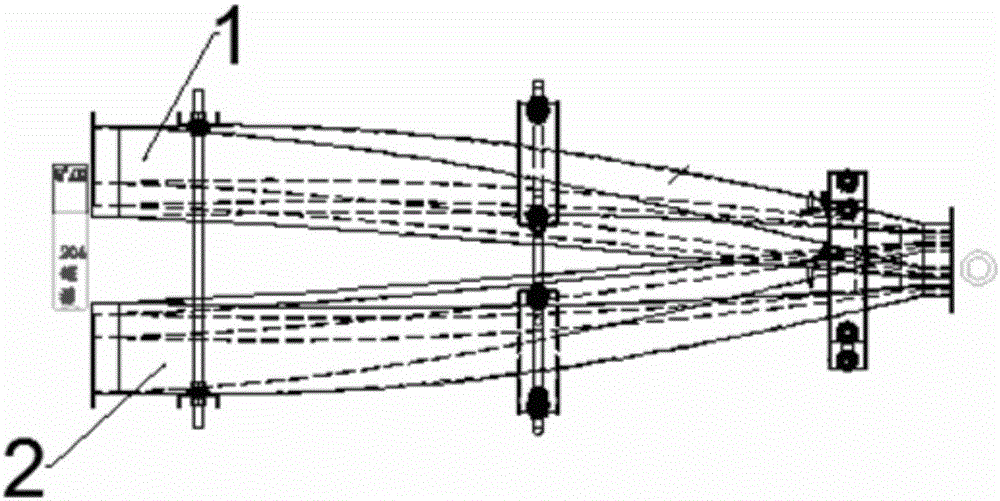

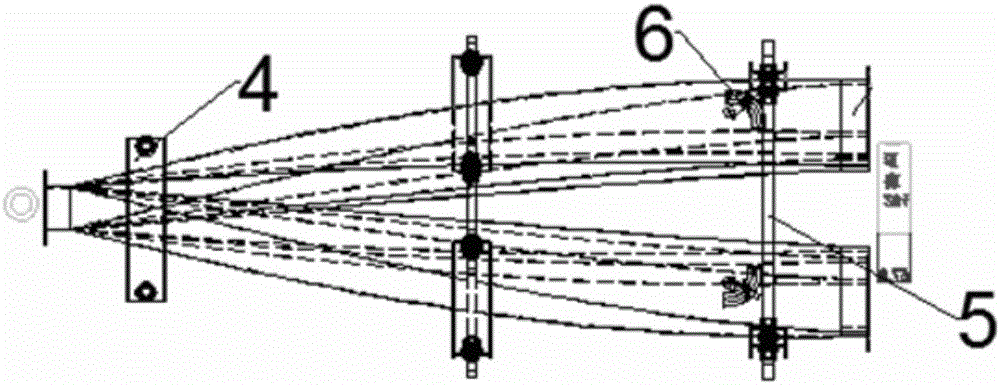

[0026] Such as Figure 1 to Figure 7 As shown, it includes upper and lower bellows. The air blowing plate is 304 mirror stainless steel. The stainless steel retaining strip and polymer wear-resistant strip are used as the guide rails of the cans to quickly transport the cans to the corresponding equipment inlets. The upper and lower bellows and wind plates rotate 90°; The side polymer wear-resistant strips can be interchanged according to the different outer diameter tanks produced, and the 90° flip air blower is a shaped product, which can be adjusted slightly (±5mm). The air blowing plate is made of 304 mirror stainless steel, and the directional blowing port is Disconnected on three sides. The ventilation fan is used as the air source to reach a certain pressure value range, and then flows in the same direction through the special directional blower port, thereby driving the cans between the upper bellows box and the lower bellows box to run and transport, achieving the pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com