Pickup and inkjet printer for circular product

A technology for inkjet printers and products, applied in manipulators, typewriters, printing and other directions, can solve the problems of inconvenient replacement of product specifications, low printing accuracy, and unstable coding, so as to achieve strong adaptability to products and high coding accuracy. , picking and coding stable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

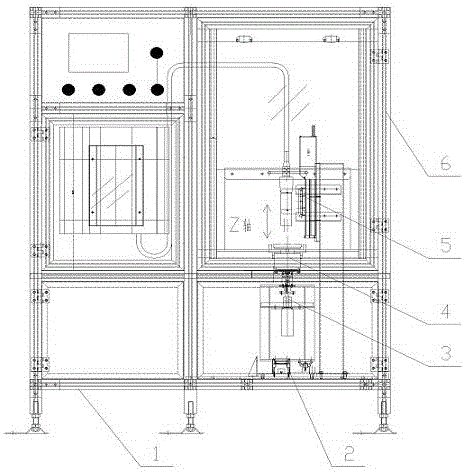

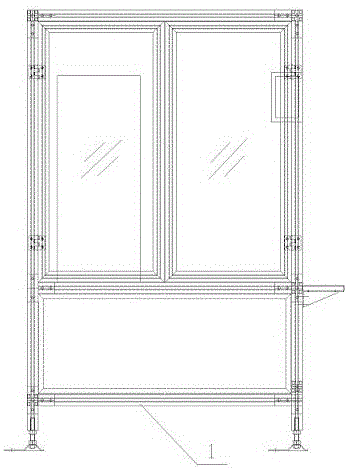

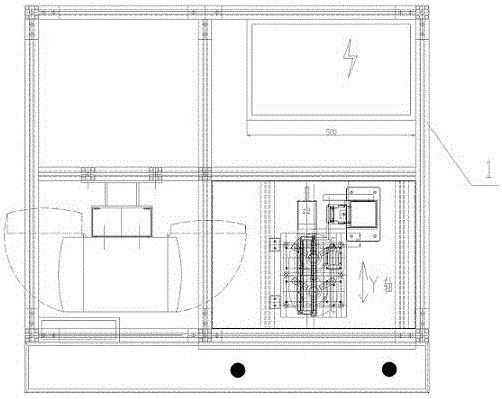

[0030] Such as Figure 1 to Figure 15As shown, the circular product pick-up inkjet printer includes a frame body mechanism 1, a horizontal movement positioning mechanism 2, a rotation positioning mechanism 3, a grabbing mechanism 4, and a vertical lift coding positioning mechanism 5, a horizontal movement positioning mechanism 2, and a rotation positioning mechanism 3. The grabbing mechanism 4 and the vertical lifting and coding positioning mechanism 5 are respectively installed on the frame mechanism 1, the rotary positioning mechanism 3 is set on the upper part of the horizontal movement positioning mechanism 2, and the grabbing mechanism 4 is set on the upper part of the rotary positioning mechanism 3, and vertically lifts The coding positioning mechanism 5 is arranged on the upper part of the grasping mechanism 4 to realize automatic positioning, automatic clamping, automatic coding and manual picking of circular objects. The frame mechanism 1 includes aluminum profiles 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com