Antiallergic skin-caring lotion and wet tissue and preparation methods of antiallergic skin-caring lotion and wet tissue

An anti-allergic and skin care milk technology, applied in the field of chemical daily necessities, can solve problems such as skin allergies, user experience discounts, and lack of skin care effects, and achieve the effect of less irritation and good anti-allergic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

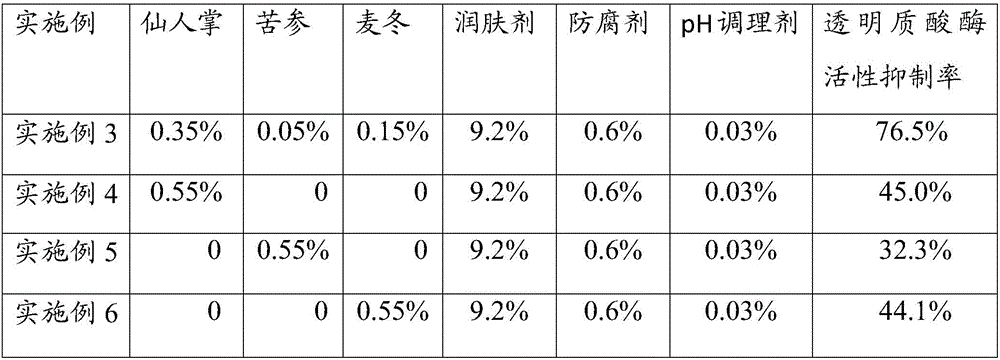

Examples

preparation example Construction

[0039] The preparation method of the above-mentioned plant extract can adopt the following steps: take the plant, coarsely crush it, add a 20-mesh sieve, dissolve it in deionized water according to a solid-liquid ratio of 1:2, heat it to 90°C, keep it warm and stir for extraction for 1 hour, and cool it to At room temperature, the extract was coarsely filtered through a 100-mesh filter, centrifuged at 5000r / min for 10 minutes, and the supernatant was fine-filtered on a cardboard with a pore size of 0.8um.

[0040] Moisturizing emollients can be selected from one or more combinations of water-soluble olive oil, water-soluble lanolin, isopropyl stearate, VE, glycerin, propylene glycol, allantoin, salicylic acid , hyaluronic acid, squalane, glyceryl stearate; wherein, the water-soluble olive oil is selected from olivem 300, olivem 400, olivem 900, olivem 1000 in one or more combinations.

[0041] Preservatives can be selected from the combination of one or more of the following g...

Embodiment 1

[0059] Step 1: add 9.2% by weight of the moisturizing emollient to an appropriate amount of water at 75°C and keep stirring, the stirring speed is 200-600rpm, and the stirring time is 10-30min; wherein, the composition of the moisturizing and emollient components and each group The weight percent of points is: Olivem300, 5%; water-soluble lanolin, 3%; VE, 1.2%.

[0060] Step 2: Add 0.55% by weight antisensitizer to the mixed solution in the previous step, stir slowly, the stirring speed is 100-500rpm, and the stirring time is 5-30min; wherein, the antisensitizer includes components and The weight percent of each component is: cactus extract, 0.35%; Sophora flavescens extract, 0.05%; Ophiopogon japonicus extract, 0.15%.

[0061] Step 3: cool down to normal temperature, add 0.05% by weight of preservative, stirring speed is 100-500rpm, and stirring time is 5-15min; wherein the preservative is phenoxyethanol.

[0062] Step 4: Add 0.03% by weight of a pH adjuster to adjust the pH...

Embodiment 2

[0065] Step 1: add 3.2% by weight of the moisturizing emollient to an appropriate amount of water at 75°C and keep stirring, the stirring speed is 200-600 rpm, and the stirring time is 10-30 min; wherein, the composition of the moisturizing and emollient components and each group The percentages by weight are: Olivem300, 1.5%; hyaluronic acid, 1%; propylene glycol, 0.7%.

[0066] Step 2: Add 1.1% by weight antisensitizer to the mixed liquid in the previous step, stir slowly, the stirring speed is 100-500rpm, and the stirring time is 5-30min; wherein, the antisensitizer includes components and The weight percentage of each component is: cactus extract, 0.7%; Sophora flavescens extract, 0.1%; Ophiopogon japonicus extract, 0.3%.

[0067] Step 3: cool down to normal temperature, add 0.5% by weight of preservative, stirring speed is 100-500rpm, and stirring time is 5-15min; wherein the preservative is cetylpyridinium chloride.

[0068] Step 4: Add 0.3% by weight of a pH adjuster t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com