Draw gear component and railway vehicle provided with draw gear component

A rail vehicle and coupler technology, which is applied in the field of rail vehicles, can solve problems such as damage to upper equipment, limited energy absorption, and narrow space at the front end of the car, achieving the effect of improving passive safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

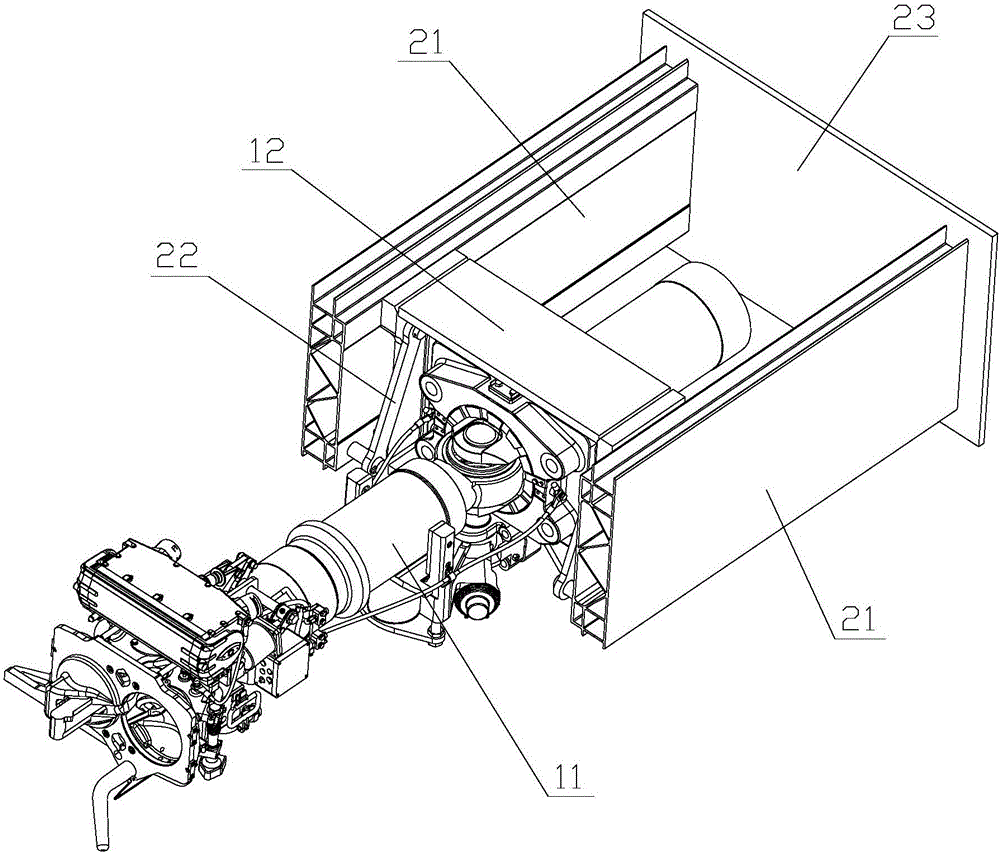

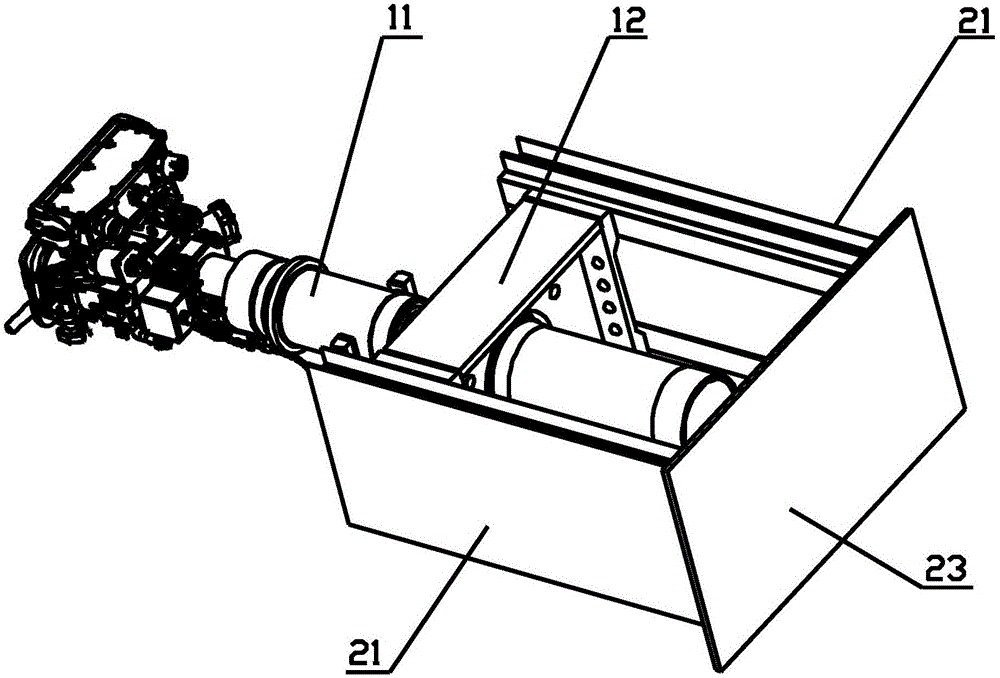

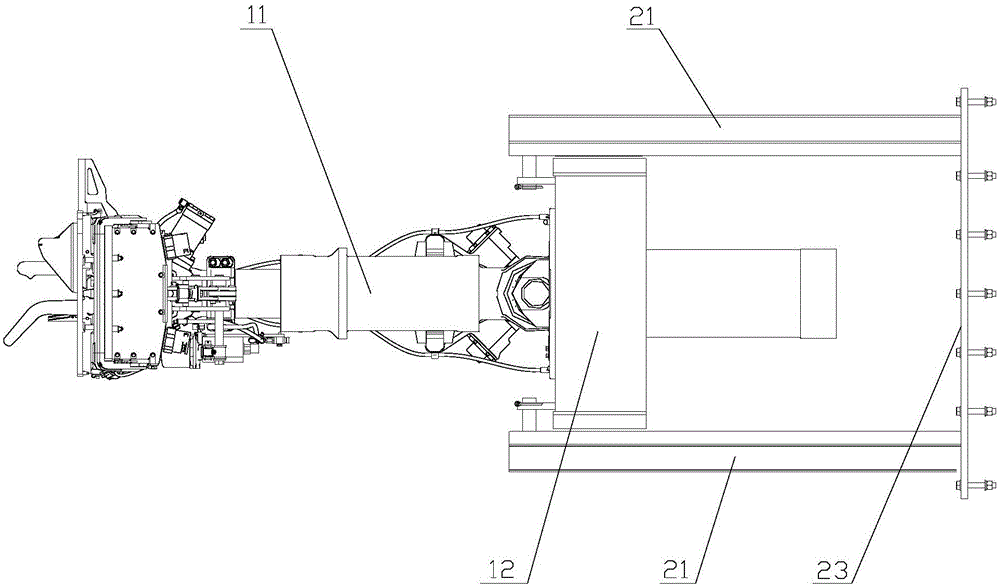

[0033] The core of the present invention is to provide a coupler assembly and a rail vehicle having the coupler assembly. The structural design of the coupler assembly can not only ensure the connecting function of the coupler during normal operation of the vehicle, but also avoid the retreat process of the coupler when the collision occurs. Intrusion into the upper part of the middle to damage the upper equipment or to fall on the track increases the risk of derailment, which can improve the passive safety of rail vehicle collisions.

[0034] In order to make those skilled in the art better understand the solution of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

[0035] Please refer to Figure 1 to Figure 4 ,in, figure 1 A schematic structural diagram of a specific embodiment of the coupler assembly provided by the present invention; figure 2 for figure 1 Schema...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com