Environmental protection and energy saving light rear projection plate making and ironing machine

An environmental protection and energy saving, all-in-one technology, applied in the field of clothing equipment, can solve the problems of occupying a large space and area, prone to falling and stepping, prolonging the training time, etc., achieving convenient operation, convenient and quick access to iron, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, so as to understand the essence of the present invention more clearly and intuitively.

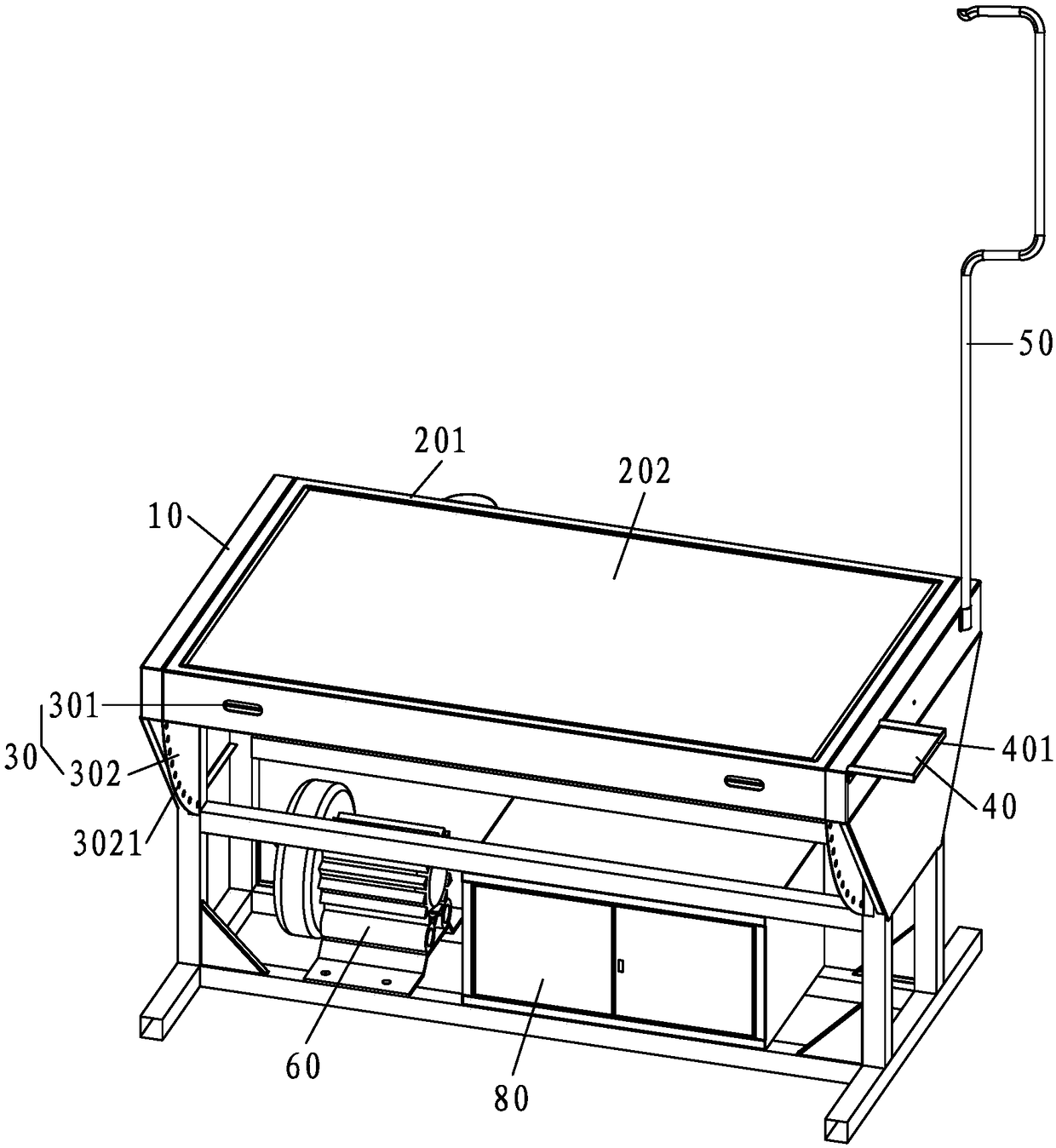

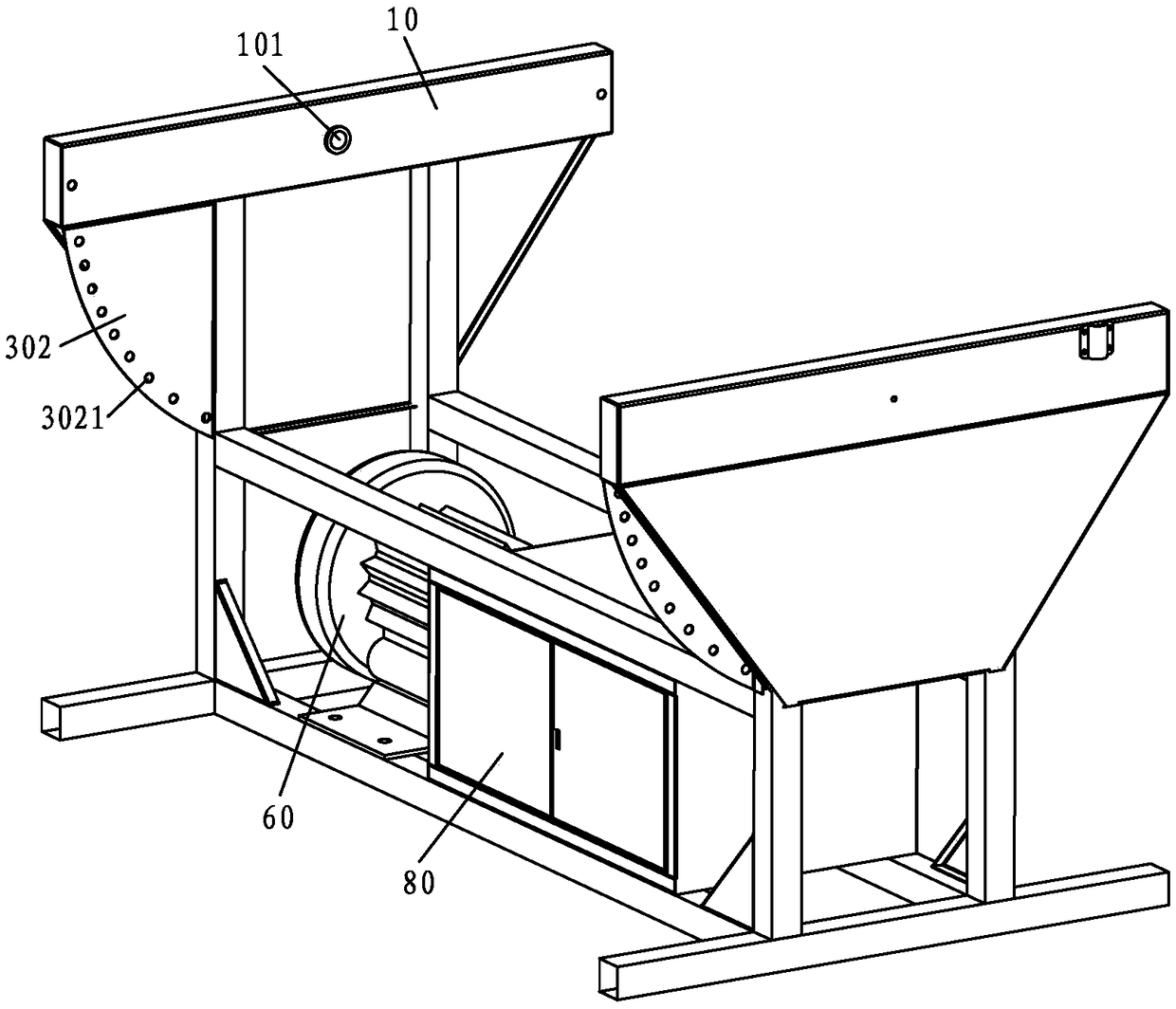

[0049] combine figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 shown;

[0050] An environment-friendly and energy-saving optical rear-projection plate-making and ironing integrated machine provided by the present invention includes a U-shaped frame 10 and a workbench 20; wherein,

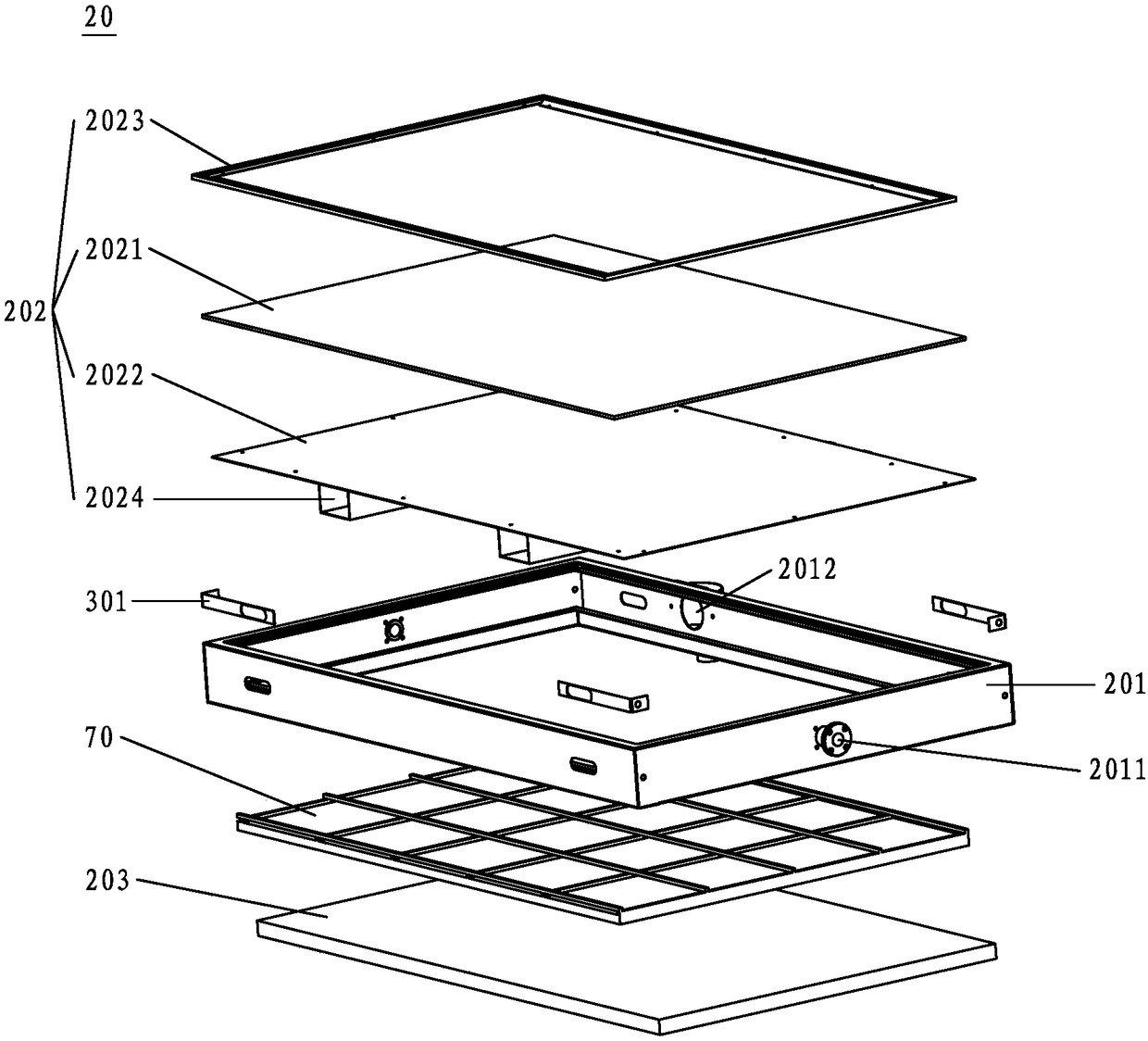

[0051]The workbench 20 includes a fixed frame 201, an ironing table 202 arranged on the upper end surface of the fixed frame 201, and a plate-making table 203 arranged on the lower end surface of the fixed frame 201; A rotating member 2011 is respectively fixed, and the two rotating members 2011 are correspondingly connected to the inner walls of the two upper ends of the U-shaped frame 10 for rotation;

[0052] When the two rotating part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com