Electric feeding combination equipment having high feeding rate

A combination of equipment and electric technology, applied in conveyors, transportation and packaging, etc., can solve the problems of materials stuck in the chain, easy slipping of the pulley, and affecting the operation of the chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

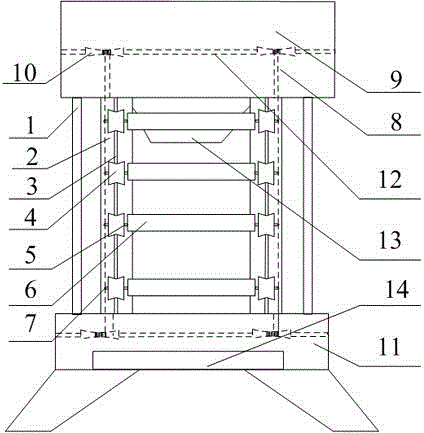

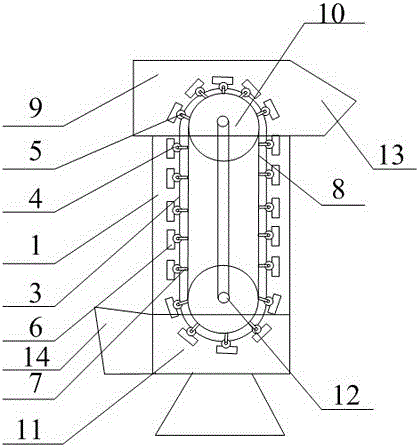

[0022] Such as figure 1 , figure 2 The shown a kind of electric feeding combination equipment with high feeding rate includes a frame 1, two chutes 2 are arranged in the middle of the frame 1, and each chute 2 is connected into an oval shape. 2 is provided with a guide rail 3 of the same length as the chute 2 and 10 pulleys 4, the circumference of the pulley 4 is provided with an annular groove matching the guide rail 3, and the pulley 4 is clamped on the guide rail 3 through the probation groove , The pulley 4 is an axisymmetric structure with respect to the annular groove; each pulley 4 is provided with a rotating shaft 5, one end of the rotating shaft 5 is connected to the hopper 6 located between the two chutes 2, and the other end is connected to the cylinder One end of the cylindrical traction shaft 7 is connected; the other end of the cylindrical traction shaft 7 is fixed with the traction rope 8; each chute 1 is provided with a circular hole matching the diameter of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com