A jig for bending and forming notebook antennas

A bending forming and notebook technology, which is applied in the field of electronic equipment processing, can solve the problems of difficult to grasp the camber, dimensional accuracy and uniformity of antenna bending, insufficient bending forming quality, low work efficiency, etc., and achieves wide application range and bending operation Convenience and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

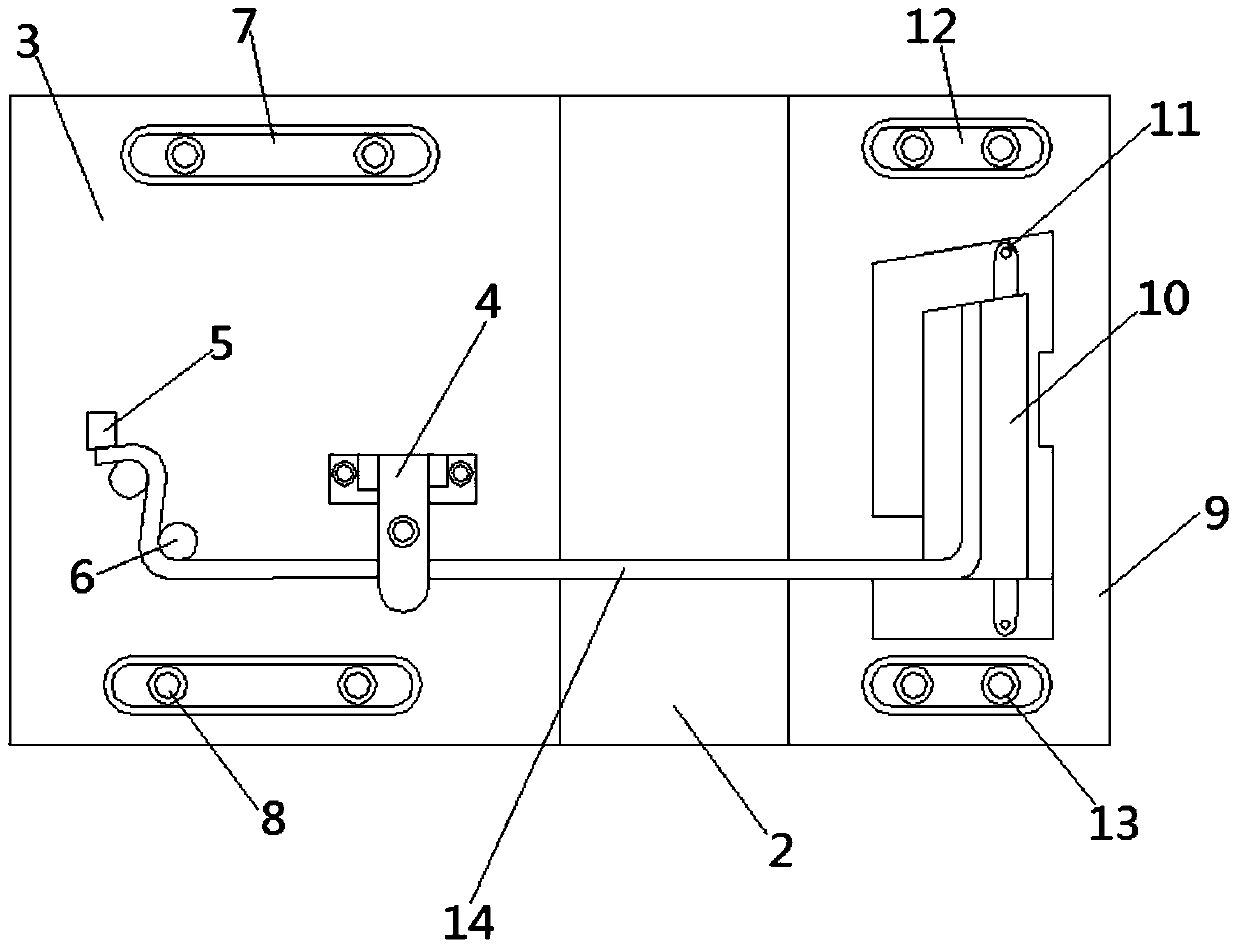

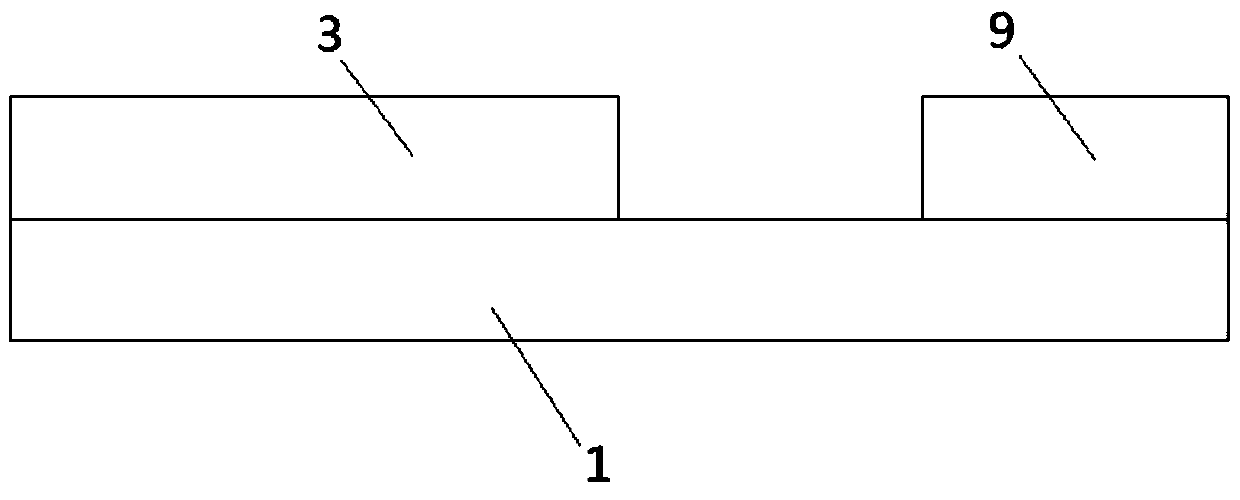

[0026] Such as Figure 1-2 As shown, a fixture for notebook antenna bending and forming, the fixture includes a fixture body 1, a bending size control module and an antenna workpiece fixing module arranged on the fixture body 1, and the bending size control module is fixed to the antenna workpiece The modules are arranged facing each other, and are respectively slidably arranged on the jig body 1 through slide rails. An antenna workpiece pick-up area 2 is provided between the bending size control module and the antenna workpiece fixing module. In the working state, according to the length of the antenna workpiece 14 Adjust the relative distance between the bending size control module and the antenna workpiece fixing module, one end of the antenna workpiece 14 is fixed on the antenna workpiece fixing module, and the other end is bent and formed by the bending size control module.

[0027] Wherein, the bending size control module includes a size control block 3 slidably arranged...

Embodiment 2

[0032] In this embodiment, the bending angle of the antenna workpiece 14 at the positioning post 6 is 75°, and the diameter of the positioning post 6 is 30 mm. All the other are with embodiment 1.

Embodiment 3

[0034] In this embodiment, there are four positioning columns 6 in the positioning column unit, and the bending angle of the antenna workpiece 14 at the positioning columns 6 is 78°. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com