Grinding working device used for kerb cleaner

A working device and washing machine technology, applied in the direction of road cleaning, cleaning methods, construction, etc., can solve the problems of not being on the same plane, serious pollution, and unequal cement application, and achieve a good contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

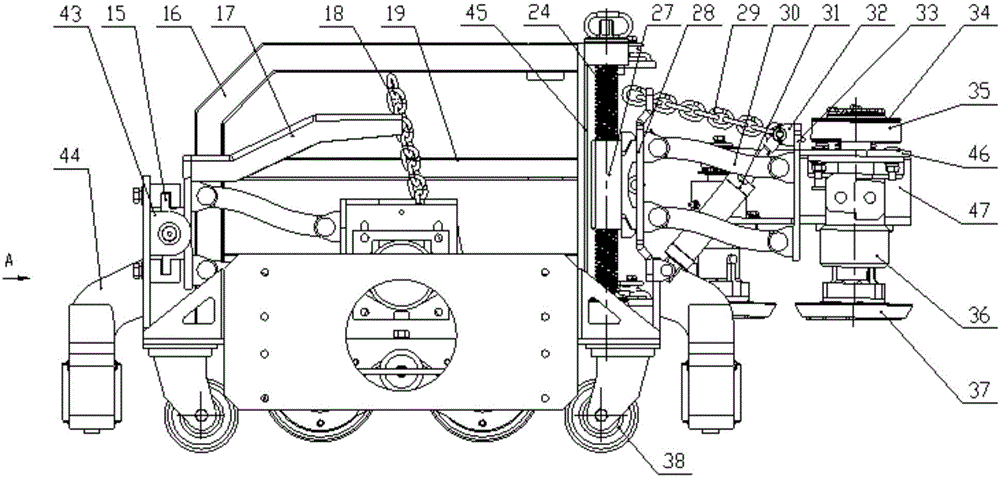

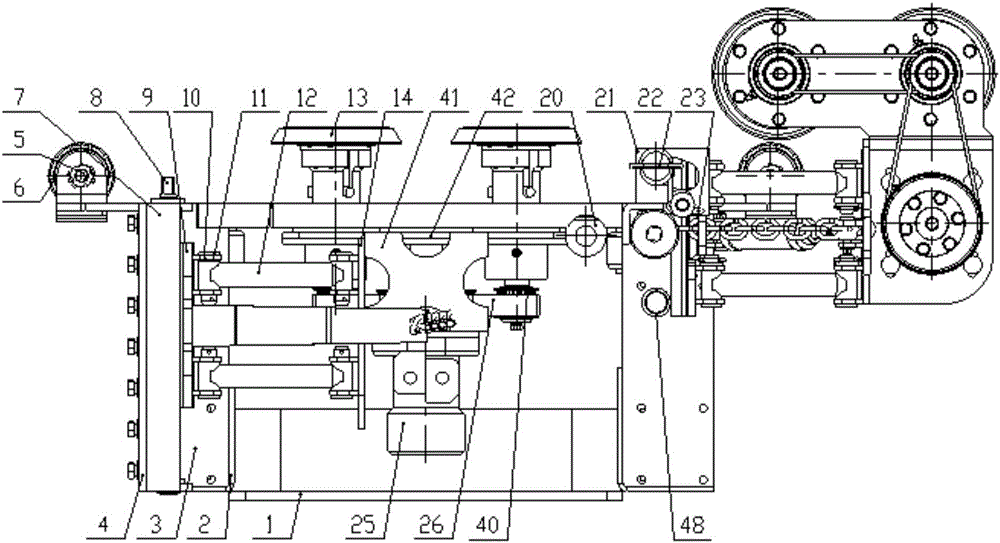

[0059] In order to further illustrate the technical solution of the present invention, in conjunction with the accompanying drawings, the specific implementation of the present invention is set forth as follows:

[0060] The invention discloses a grinding working device used on a roadside stone cleaning machine. ", and then connected with the curb stone cleaning machine to realize the process of cleaning and grinding while advancing. In order to polish and clean the horizontal surface and the side elevation of the curb stone, the grinding work The grinding connection bracket assembly of the device is equipped with two sets of grinding devices, the side elevation grinding and the horizontal surface grinding, which are independent of each other and can work at the same time. The device of the present invention better adapts to the abnormal working conditions of the ground slope and the horizontal surface and side elevation of the curb, so that the distance between the device of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com