A single-cell factory for efficiently synthesizing α-aminobutyric acid and its construction and application

An aminobutyric acid, single-cell technology, applied in the field of microorganisms, can solve the problems of high cost, increased production cost of α-aminobutyric acid, cumbersome process and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

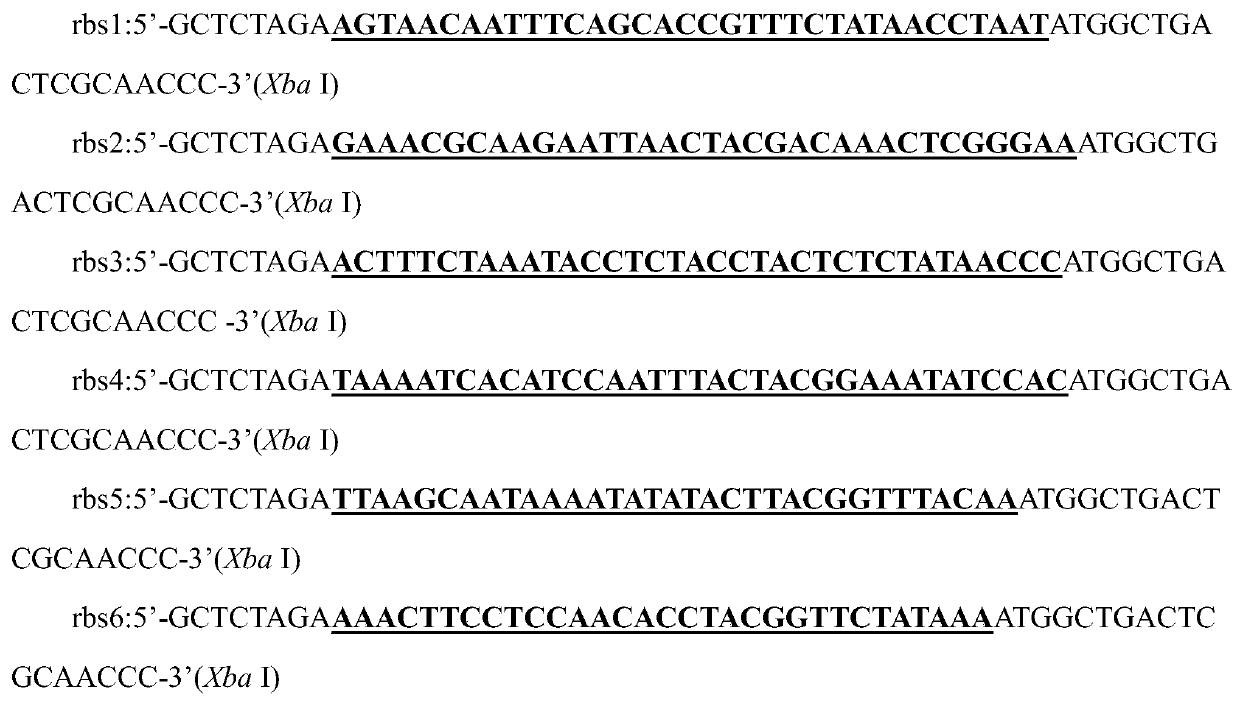

[0038] Example 1: The rbs sequence optimization of L-threonine deaminase and the construction of recombinant L-threonine deaminase Escherichia coli

[0039] [1] Combining the L-threonine deaminase gene ltd sequence from Escherichia coli with the T7 promoter, we designed rbs sequences with different expression intensities according to its expression in Escherichia coli, and then sent them to Shanghai Sangon Biotech for gene expression synthesis. PCR primers include primers rbs1, rbs2, rbs3, rbs4, rbs5, rbs6 and L-threonine containing rbs sequences with different expression intensities (indicated in bold with underline, and the sequences are shown in SEQ ID NO: 1 to SEQ ID NO: 6) The terminal primer ltdR of the acid deaminase gene (sequences such as SEQ ID NO: 7 to SEQ ID NO: 13).

[0040]

[0041] ltdR: 5'-CGGGATCCTTAACCCGCCAAAAAGAACCTG-3' (BamH I)

[0042] [2] Use primers containing rbs sequences with different expression intensities and terminal primer ltdR to form a pri...

Embodiment 2

[0047] Example 2: Construction of recombinant plasmids and recombinant bacteria co-expressing L-threonine deaminase and L-amino acid dehydrogenase

[0048] [1] Genomic DNA of Bacillus cereus, Rhodococcus, Bacillus subtilis and Streptomyces coelicolor were used as templates.

[0049] [2] Design L-amino acid dehydrogenase gene primers according to the restriction site of L-amino acid dehydrogenase gene sequence and pET-28a plasmid, including the L-leucine dehydrogenase gene Bcldh of Bacillus cereus ( Primers are PBcldhF, PBcldhR), Rhodococcus L-phenylalanine dehydrogenase gene Rjpdh (primers are PRjpdhF, PRjpdhR), Bacillus subtilis L-alanine dehydrogenase gene Bsadh (primers are PBsadhF, PBsadhR) , the valine dehydrogenase gene Scvdh of Streptomyces coelicolor (primers are PScvdhF, PScvdhR). The primer sequences are as follows (such as SEQ ID NO: 14 to SEQ ID NO: 21):

[0050] PBcldhF: 5'-CGGGATCCAAGGAGATATACATGACATTAGAAATCTTCG-3'(BamH I)

[0051] PBcldhR: 5'-CGAGCTCTTAGCGACG...

Embodiment 3

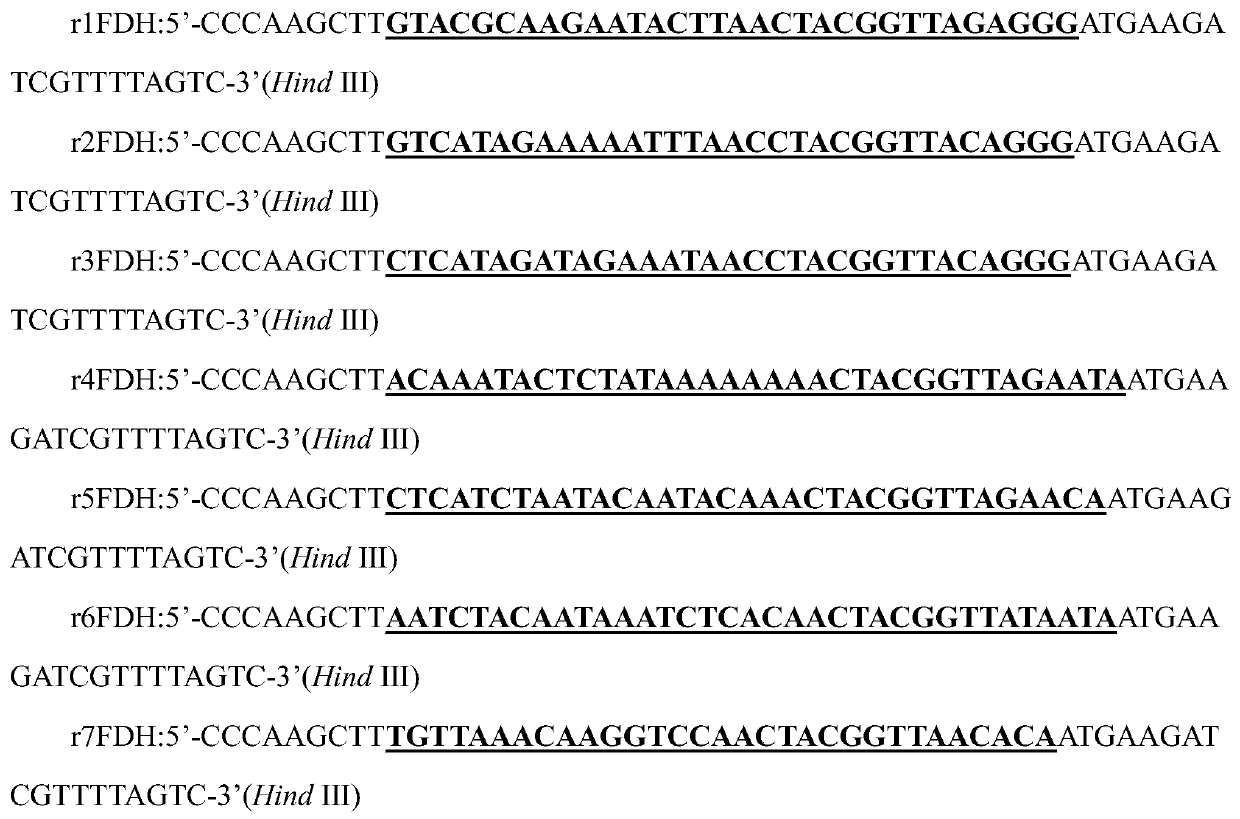

[0061] Example 3: Construction of recombinant Escherichia coli providing cofactor NADH circulating dehydrogenase and construction of recombinant Escherichia coli optimized for the promoter and rbs sequence of formate dehydrogenase

[0062][1] According to the gene sequence of the dehydrogenase that provides the cofactor NADH cycle from different sources and the restriction site connected in series to the pET-28a plasmid, primers are designed, including the formate dehydrogenase fdh of Candida boidinii ( The primers are PfdhF, PfdhR), the glucose dehydrogenase Bsglcdh of Bacillus subtilis (the primers are PBsglcdhF, PBsglcdhR), the glucose dehydrogenase Ppglc of Pseudomonas putida (the primers are PPpglcdhF, PPpglcdhR). Carry out PCR with corresponding primers, genome template respectively, obtain the gene fragment of the dehydrogenase that provides the cofactor NADH circulation of corresponding bacterial strain origin, connect it with pET-28a plasmid (nucleotide fragment and pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com