Efficient telegraph pole character spraying device

A utility pole, high-efficiency technology, applied in power transmission devices, typewriters, printing, etc., can solve problems such as labor cost, unstable spray effect, and impact on the health of operators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

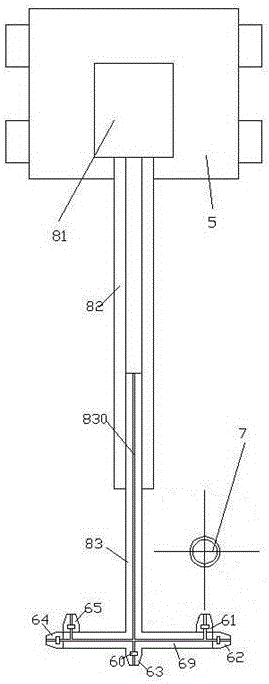

[0011] Combine below Figure 1-6 The present invention will be described in detail.

[0012] According to the embodiment of the present invention, the high-efficiency spraying device for utility pole 7 includes a spraying template installed on the utility pole 7, a traveling frame part 5 on which traveling rollers 50 are installed, and a traveling frame part located at the The lifting device 51 on the 5 and the spraying equipment 81 driven by the lifting device 51, the spraying equipment 81 includes a body part connected to the lifting device 51, a threaded sleeve driven by a motor in the body part 82 and the telescopic screw 83 threadedly driven by the threaded sleeve 82, the telescopic screw 83 is provided with an axially extending through hole 830 for transmitting the spraying liquid, and the through hole 830 is located in the telescopic screw 83 The spraying execution assembly 6 at the end is fluidly connected, and the spraying execution assembly 6 is slidably matched wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com