Traveling wave ultrasonic motor containing flexible shaft

An ultrasonic motor, flexible shaft technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the problems of poor motor running stability and poor uniformity, and achieve enhanced The effect of load capacity, elimination of clearance, and improvement of operating stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

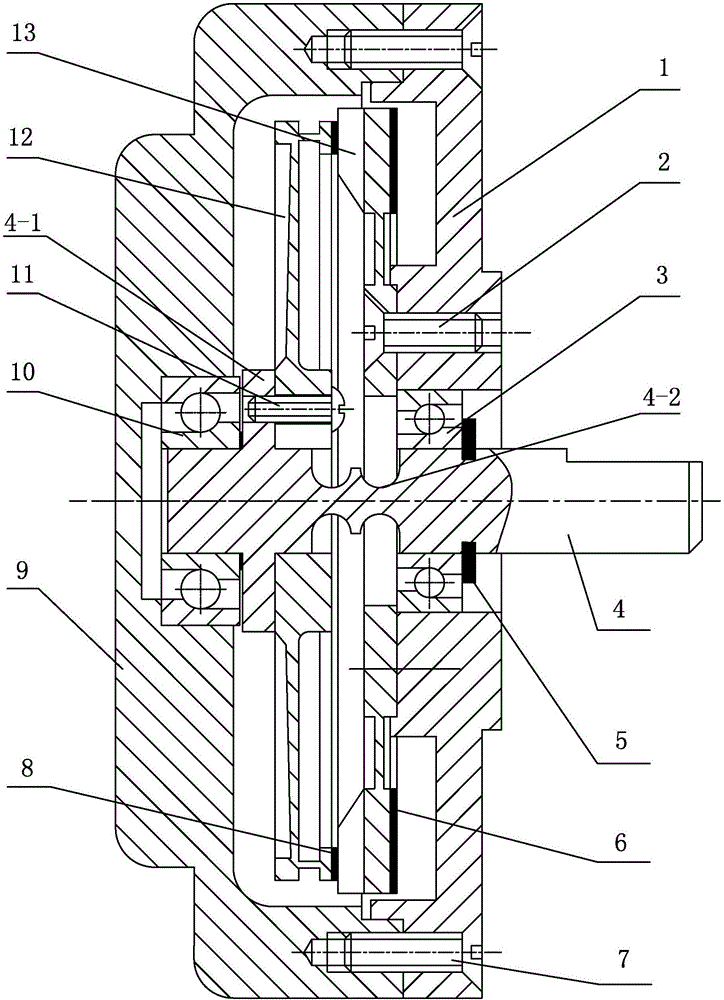

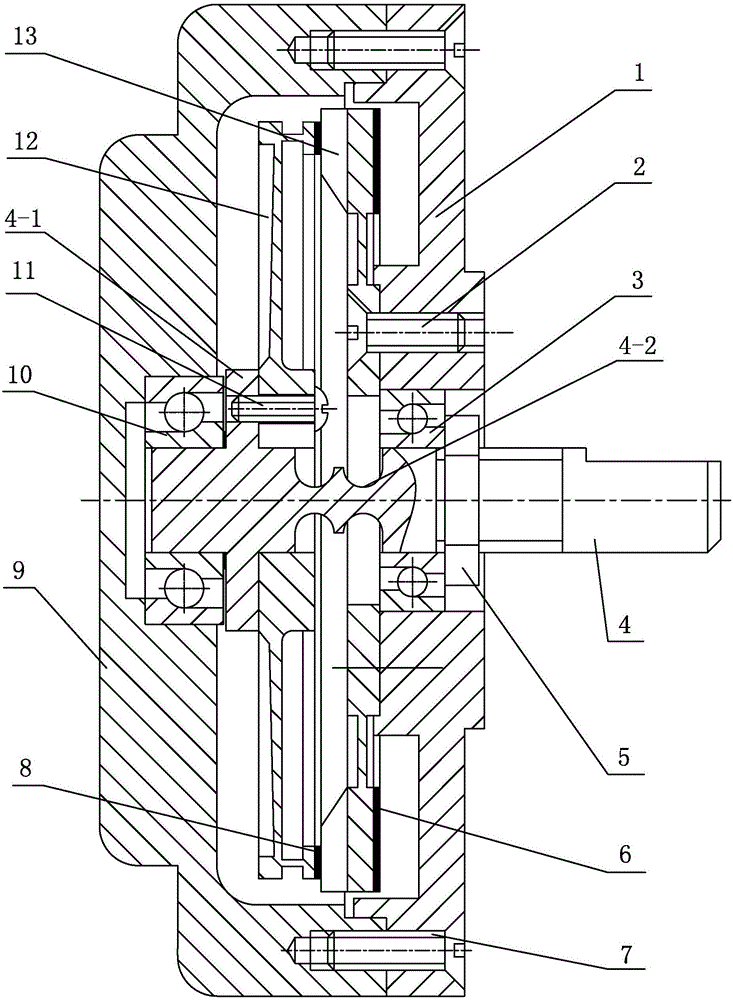

[0018] Specific implementation mode one: combine Figure 1-Figure 3 Explain that a traveling wave ultrasonic motor with a flexible shaft in this embodiment includes a base 1, a front angular contact ball bearing 3, a flexible shaft 4, a housing 9, a rear angular contact ball bearing 10, a rotor 12 and a stator 13;

[0019] The housing 9 and the base 1 are detachably connected, the base 1 is equipped with a front angular contact ball bearing 3, the housing 9 is equipped with a rear angular contact ball bearing 10, and the flexible shaft 4 is installed on the front angular contact ball bearing 3 and the rear angular contact ball bearing 10; the rotor 12 and the stator 13 are arranged between the front angular contact ball bearing 3 and the rear angular contact ball bearing 10, the rotor 12 is arranged adjacent to the housing 9 and installed on the annular rib 4-1 of the flexible shaft 4, The stator 13 is installed on the base 1, a layer of annular friction material 8 in contact ...

specific Embodiment approach 2

[0025] Specific implementation mode two: combination figure 1 with figure 2 Note that a traveling wave ultrasonic motor with a flexible shaft in this embodiment further includes a circlip 5 , and the front angular contact ball bearing 3 preloads the inner ring of the stator 13 through the circlip 5 . With such setting, the preload is convenient, reliable and easy to use. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0026] Specific implementation mode three: combination figure 1 with figure 2 Note that a traveling wave ultrasonic motor with a flexible shaft in this embodiment also includes a pre-tightening nut 15, the shaft section of the flexible shaft 4 close to the front angular contact ball bearing 3 is a threaded shaft section, and the pre-tightening nut 15 is screwed on the threaded shaft. On the shaft section, the front angular contact ball bearing 3 preloads the inner ring of the stator 12 through the preload nut 15 . In such a setting, the pre-tightening nut exerts a pre-tightening force, which improves the uniformity of the pre-pressure loading. When used with a flexible shaft, the motor's running stability and load capacity can be further improved. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wear rate | aaaaa | aaaaa |

| Wear rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com