Pushing construction method of single-line railway steel truss bridge utilizing guide beam

A technology of pushing construction and single-track railway, which is applied in the direction of erecting/assembling bridges, bridges, and bridge materials. Solve the effect of limited site and small environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

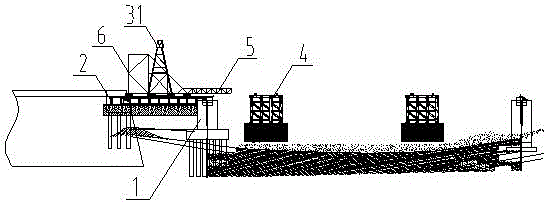

[0025] Example: see Figure 1 to Figure 6 , a method for pushing construction of a single-track railway steel truss bridge using a guide beam, comprising the steps of:

[0026] 1) Build two sets of fixed support bent frames on the roadbed on one side of the river, each set of fixed support bent frames includes multiple fixed support bent frames 2 distributed along a straight line, and extend to the side where the river is located and close to the river The pier 1. A guide rail I is respectively laid on the two sets of fixed support bent frames. In practice, a beam is laid on each fixed support bent frame 2, and the guide rail I is laid on the beam and fixedly connected with the beam. The height of the guide rail I is higher than that of the pier 1, and its length direction is consistent with the extension direction of the fixed support bent frame group. Several wheel boxes are arranged on the guide rail I. Wherein, the shifting wheel box includes a box shell, a traveling whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com