A target plate assembly, laser line marking instrument assembly and working method thereof

A technology of laser marking instrument and working method, which is applied in the direction of instruments, measuring instruments, active optical measuring devices, etc., can solve the problems of delay in construction period, material loss, waste, etc., and achieve the effect of convenient operation and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

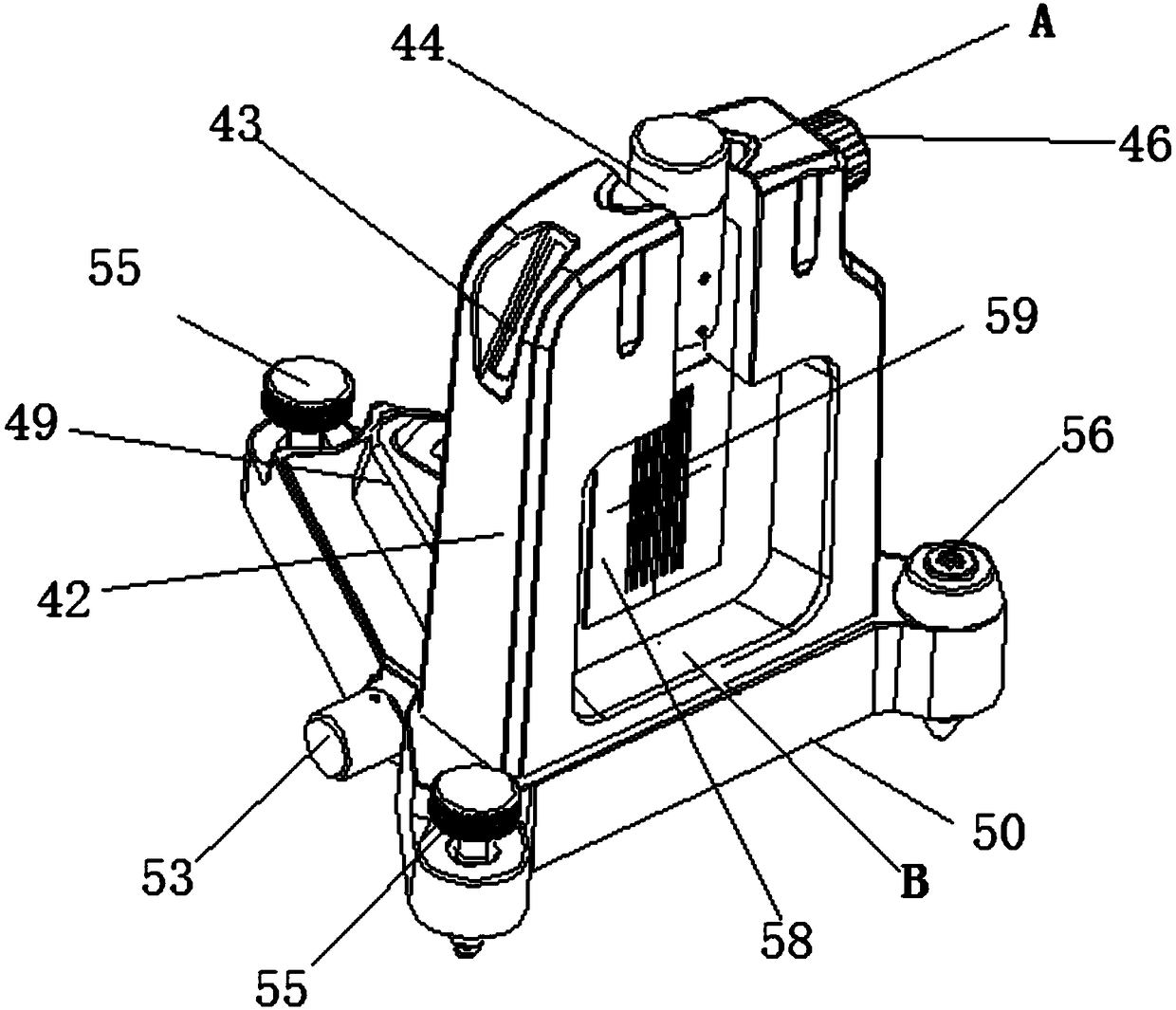

[0039] Such as Figure 3 to Figure 5 As shown, the target plate assembly 4 of the present embodiment includes a target plate 40, a target plate base 50, a target plate adjustment seat 49, a target plate support 42, a first laser assembly 43, a second laser assembly 44, and the target plate support 42 is fixedly arranged On the target plate adjustment seat 49, the target plate 40 is fixedly arranged in the target plate support 42, the top of the target plate 40 is provided with a rotatable rotating shaft 45, and the rotating shaft 45 is rotatably matched with the target plate support 42 through the washer 48 and the locking nut 47. , and is fixedly connected with the knob 46; the target plate front end surface 58 is provided with a scale paper 59, and the marking line of the scale paper 59 is used as the reference line of the target plate 40, and the reference line is perpendicular to the axis of the rotating shaft 45, and the second laser assembly 44 Fixedly arranged on the ro...

Embodiment 2

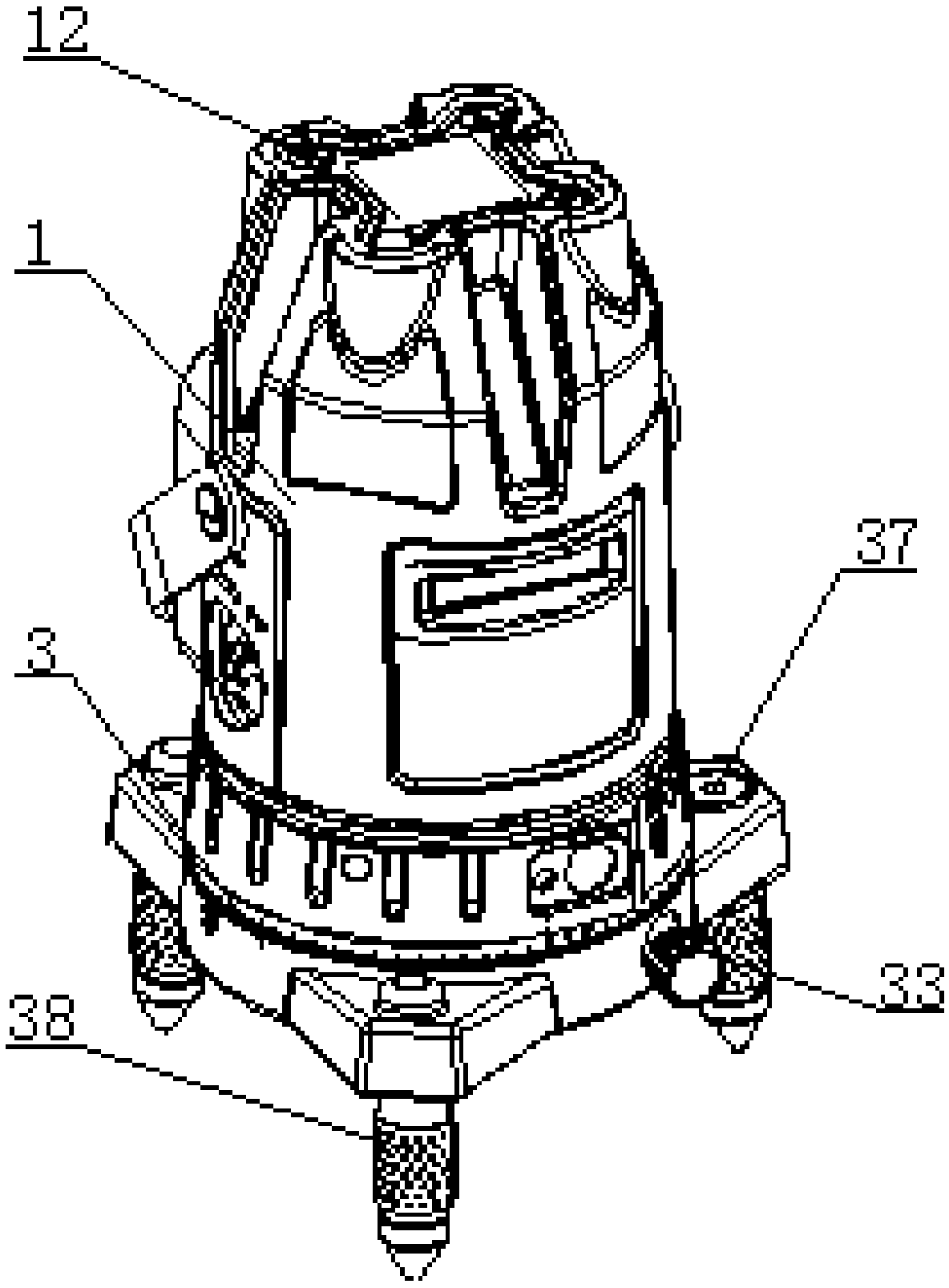

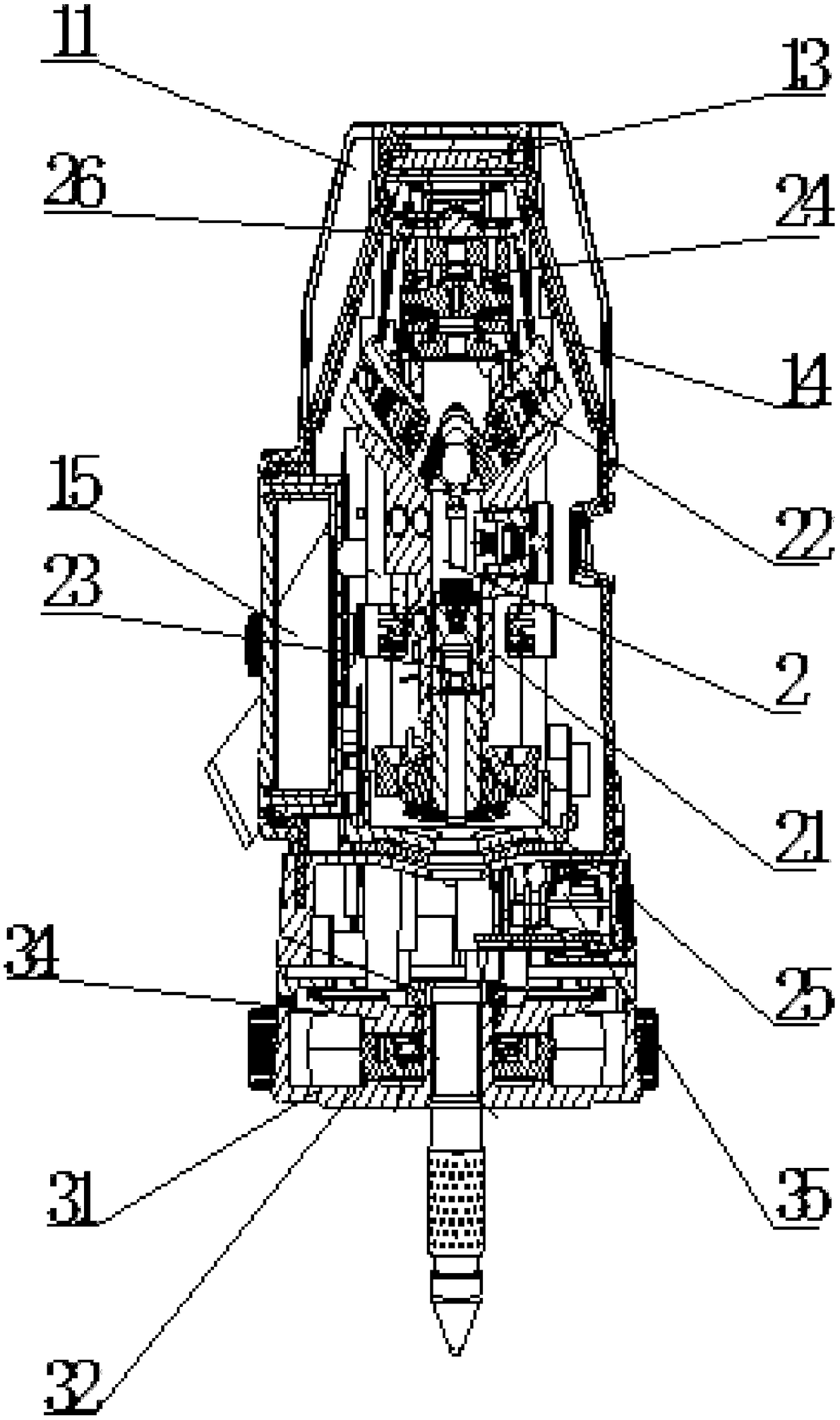

[0041] The laser line marking assembly using the above-mentioned target plate assembly 4 includes a laser line marking 1 and a watch display device 6, such as Figure 1 to Figure 2 As shown, the laser marking instrument 1 mainly includes a casing 11, a movement part 2, and a base part 3. The casing 11 mainly includes an operation panel 12 for operation and a display screen for displaying data (LCD display or LED display device) 13, a light output window 14 and a battery box part 15 for placing batteries.

[0042] The base part 3 mainly includes a bottom shell 31, a base gear 32, a worm knob part 33, a chassis part 34, a distance measuring movement assembly 35, a blister 37, and a leg part 38; The lower end of 34 is connected to the base gear 32, the base gear 32 is placed in the bottom housing 31, and the worm knob part 33 passes through the bottom housing 31 and meshes with the base gear 32 for driving the chassis part 34 to rotate. The blister 37 is arranged on the upper en...

Embodiment 3

[0048] The application of the above-mentioned laser marking instrument components in the installation of partitions in large venues, such as Figure 9 shown, including the following steps:

[0049] A. According to the need to partition the wall 71, first determine the starting point of the partition 73 on the ground 70, and mark it on the ground 70; place the laser marking instrument 1 above the starting point, and adjust the leg part 38 of the laser marking instrument 1 To make the laser line marking instrument 1 horizontal; start the laser line marking instrument 1 so that the point laser emitted by the fourth laser assembly 23 is aimed at the starting point, and rotate the chassis part 34 of the laser line marking instrument 1 so that the third laser assembly 22 emits The vertical laser 16 is perpendicular to the wall 71 and the ceiling 72, then the distance measuring laser 18 emitted by the distance measuring core assembly 35 is parallel to the wall 71 and the ceiling 72, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com