Spherical tank used for containing low-temperature medium

A low-temperature medium and spherical tank technology, which is applied to fixed-capacity gas storage tanks, container discharge methods, pressure vessels, etc., can solve the problems of small interlayer space between inner and outer tanks, the influence of temperature sensors and cables on the appearance, and the complex process structure of spherical tanks, etc. , to achieve the effect of improving electrical safety, ensuring the effect of heat preservation, and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further illustrate the principle and structure of the present invention, preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

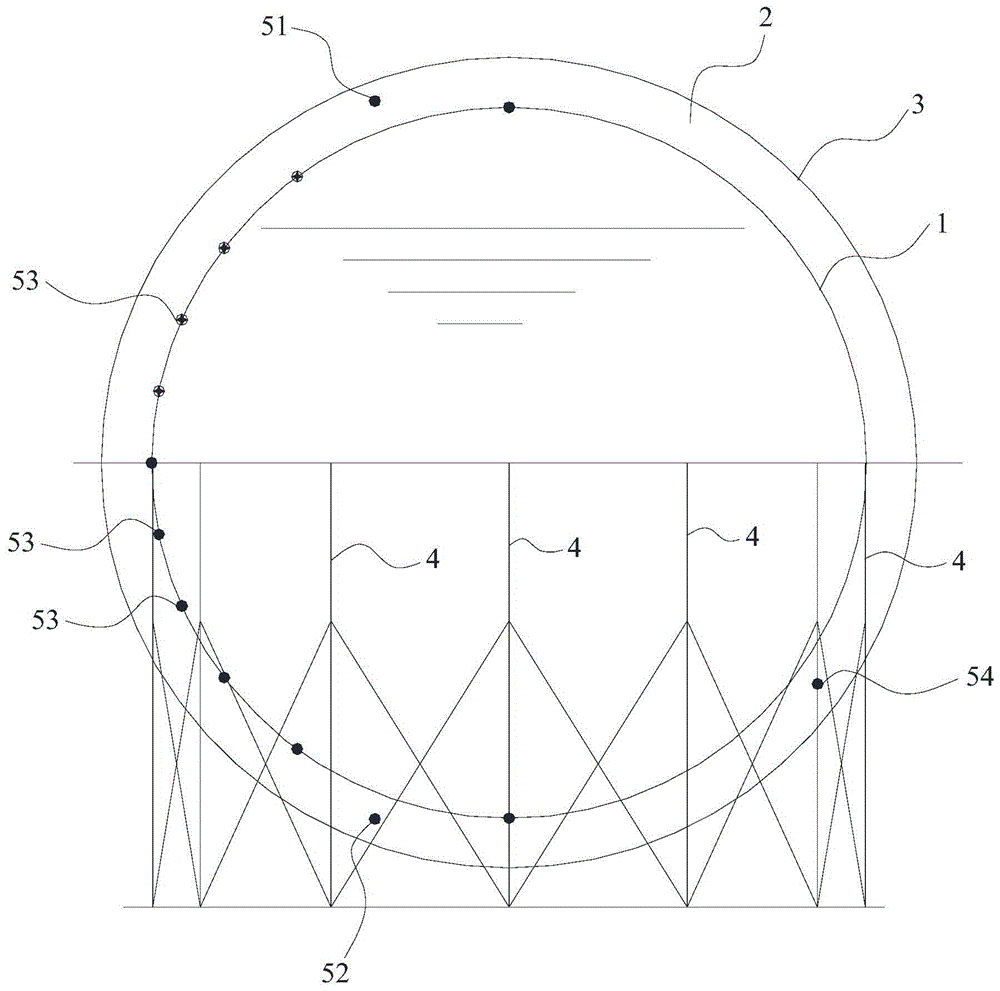

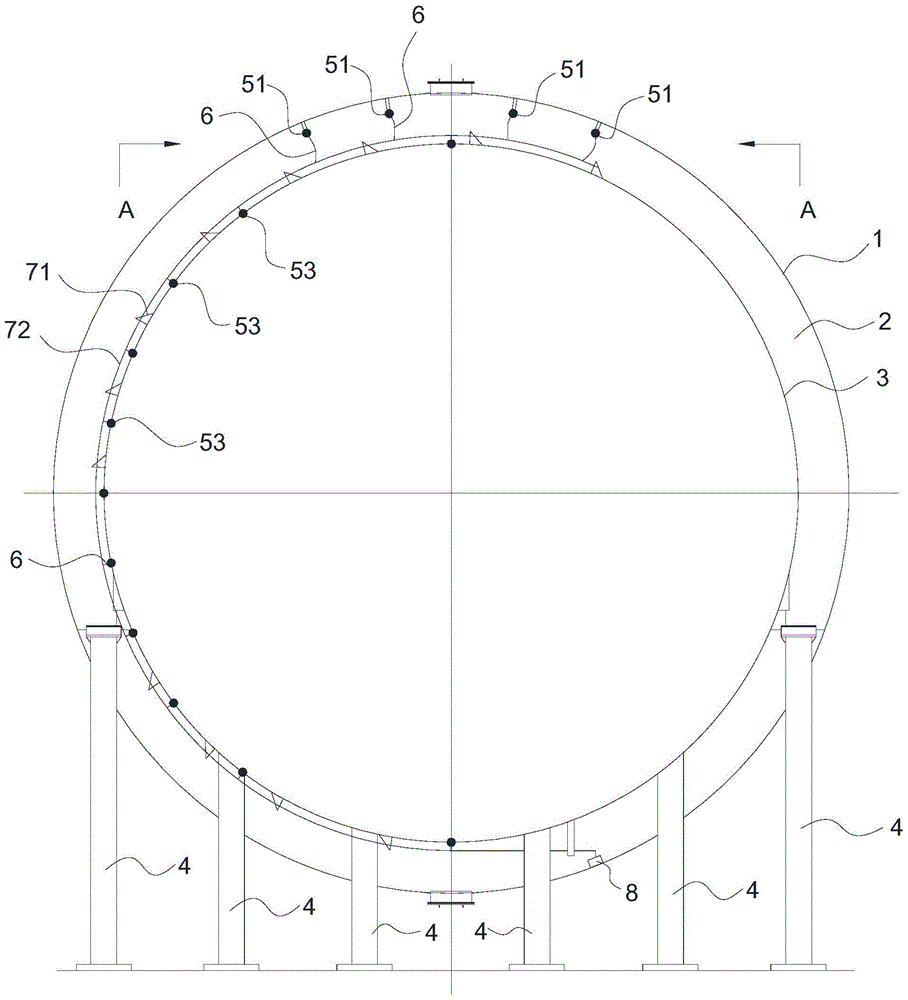

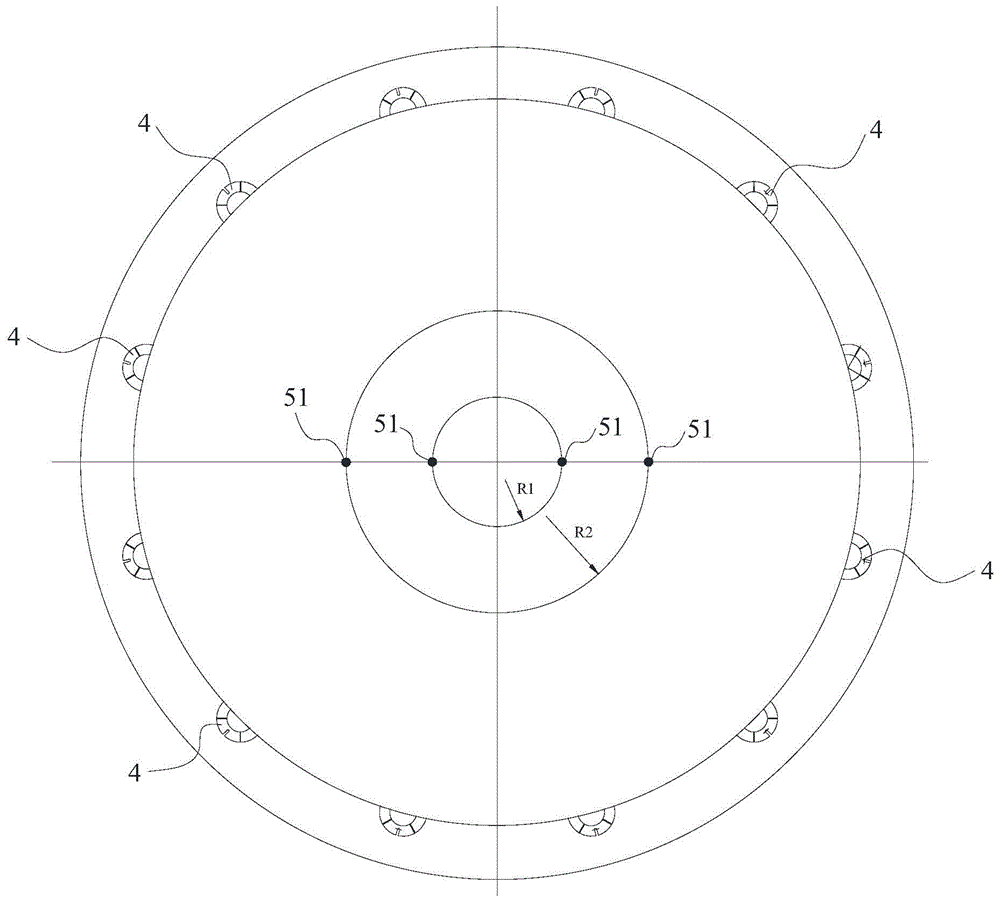

[0035] refer to figure 1 , the spherical tank for loading cryogenic medium of the present invention comprises: a spherical outer tank 1, a spherical inner tank 3 located in the spherical outer tank 1, an interlayer 2 formed between the outer tank 1 and the inner tank 3, for supporting The legs 4 of the inner tank 3 and the temperature monitoring system for monitoring the temperature of the spherical tank.

[0036] The outer tank 1 is usually made of carbon steel, and the interlayer 2 between the inner tank 3 and the outer tank 1 is filled with pearlescent sand to insulate the inner tank 3 from heat.

[0037] The inner tank 3 is usually made of stainless steel, and its inner space can be loaded with low-temperature medium, such as: LNG (liquefied natural gas), li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com