Engine air inlet pipe and engine system

A technology of engine and air intake pipe, which is applied in the direction of engine components, machine/engine, charging system, etc., can solve the problems of safe driving of the car and affect the driving performance of the car, achieve long service life, easy to realize transformation, ensure stability and safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The engine intake pipe and the engine system of the present invention will be further described in detail in conjunction with the drawings and specific embodiments below, but the detailed description does not constitute a limitation of the present invention.

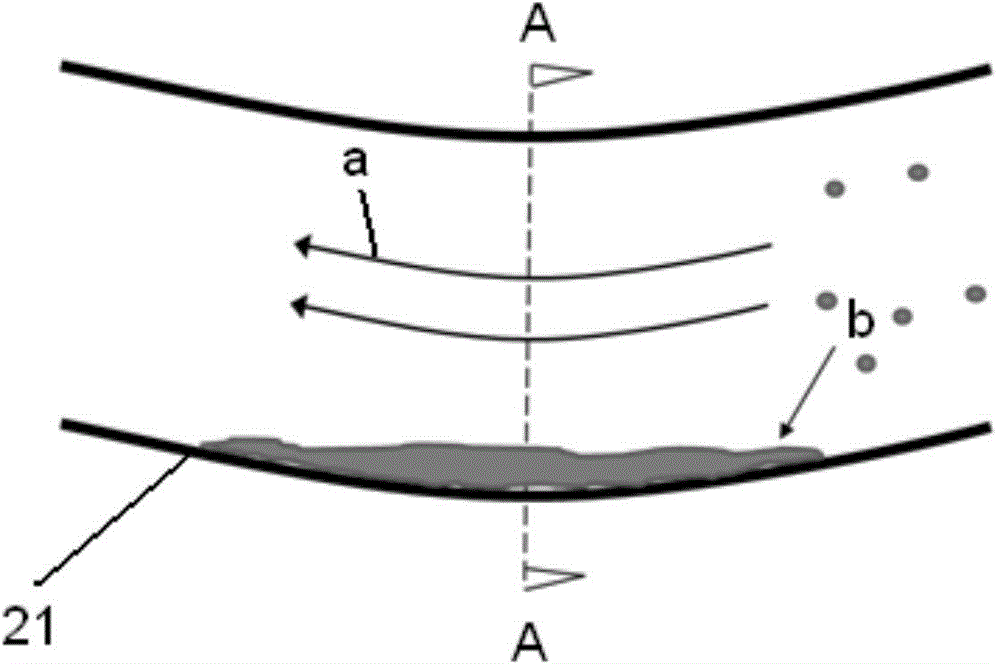

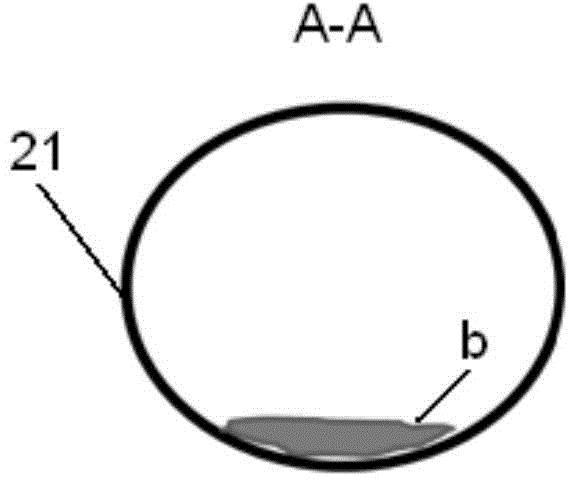

[0059] Figure 5 to Figure 8 The structure and state of the engine intake pipe in an embodiment of the present invention are respectively shown.

[0060] like Figure 5 to Figure 8 As shown, along the flow direction X of gas a, the engine intake pipe 10 has an inlet port 11 and an outlet port 12. Gas a enters from the inlet port 11 along with the flow direction X and leaves from the outlet port 12. The bottom of the air pipe 10 is continuously provided with an elastic portion 13, which can protrude inward or outward according to the pressure difference between the inside and outside of the engine intake pipe 10, for example, when the engine is working, When the trachea is inhaled, the air pressure inside the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com