Torsional spring driven shear fork extending arm

An extension arm and torsion spring technology, applied in the field of extension arms, can solve the problems of complex control, poor manufacturing process, slow response, etc., and achieve the effect of good seismic performance, rapid response, and large folding ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

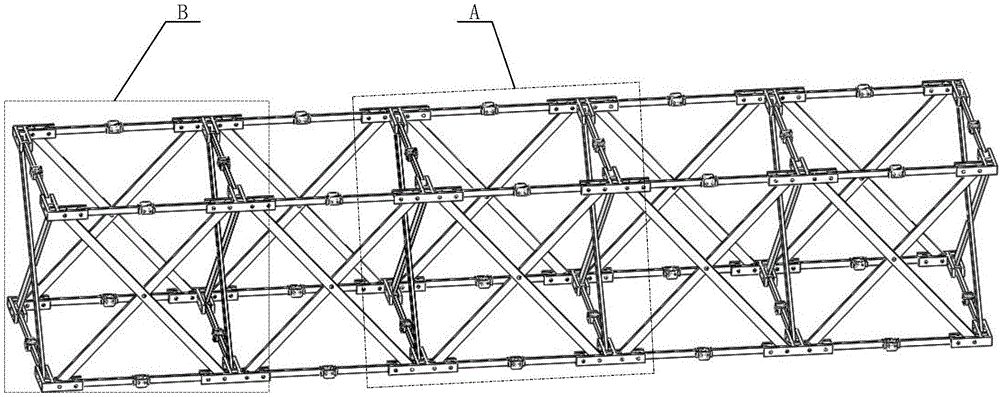

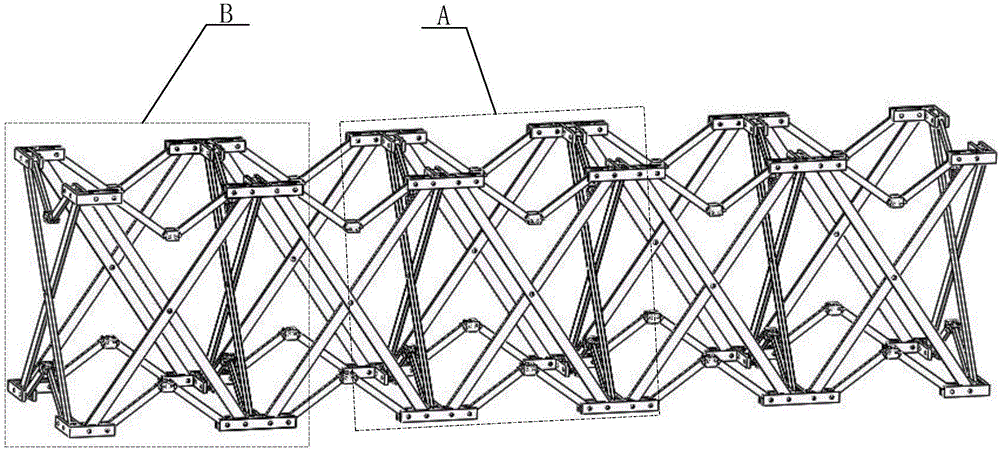

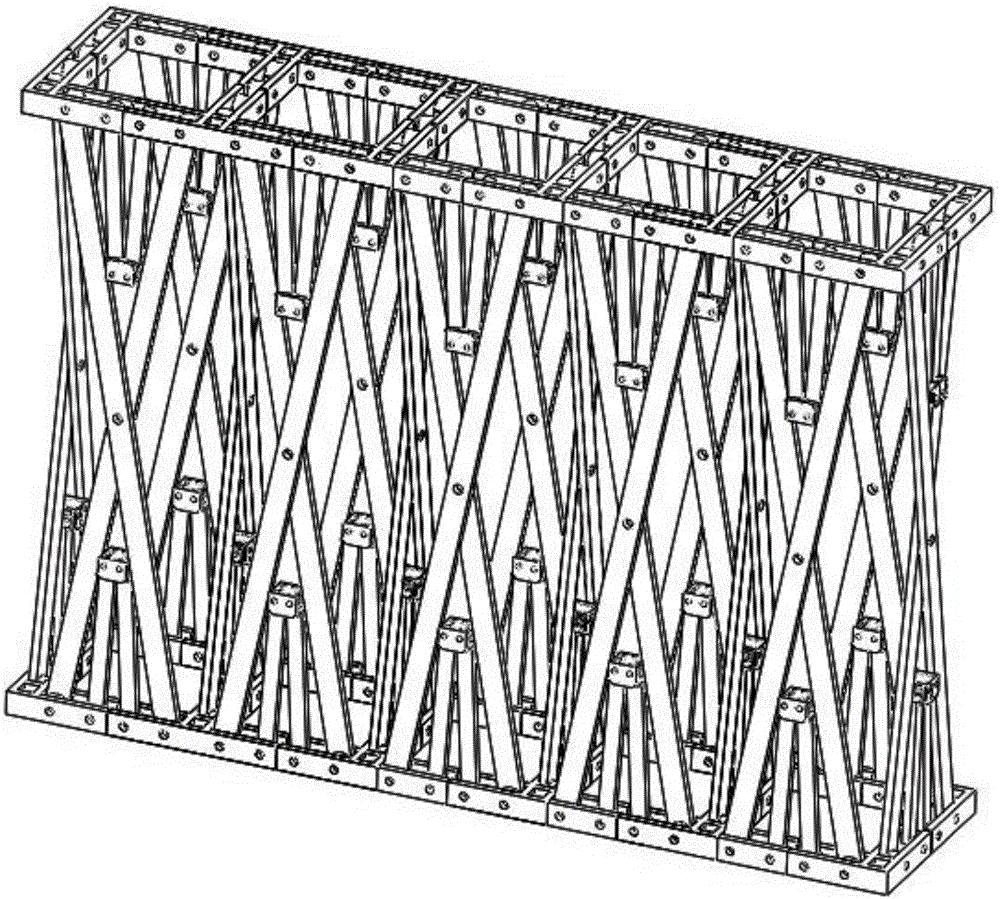

[0024] exist figure 1 , figure 2 and image 3 In the three-dimensional schematic diagram of the shown torsion spring driven scissor type extension arm, the present invention mainly consists of two end hexahedron folding units B, such as Figure 5 As shown, there are 3 intermediate hexahedral folding units A between them, such as Figure 4 As shown, the scissor-type extension arm driven by torsion spring is formed, and its expansion and contraction are hexahedral frames. The adjacent middle hexahedral folding units share a plane folding unit C and are connected by four middle faceplates 1. The unit and its adjacent middle hexahedron folding unit also share a plane folding unit and are connected by four middle faceplates.

[0025] exist Figure 6 and Figure 7 In the three-dimensional schematic diagram of the plane folding unit and the four connected faceplates shown, the plane folding unit C includes two scissor levers 2, four connecting rods 3 and two sets of torsion spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com