Kettle forming mold

A technology for forming molds and kettles, which can be applied to home appliances, other home appliances, and household components, etc. It can solve the problems of breaking, poor thermal conductivity, and low strength, and achieve the effect of convenient drafting slope and guaranteed demoulding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

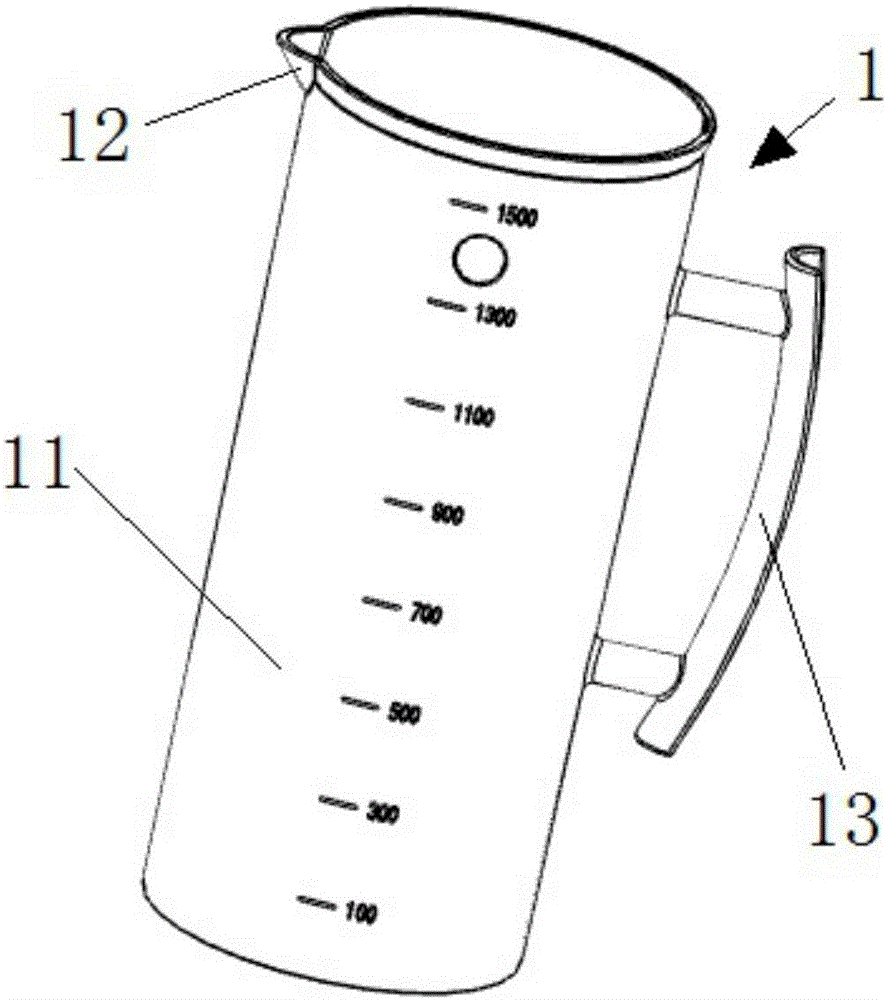

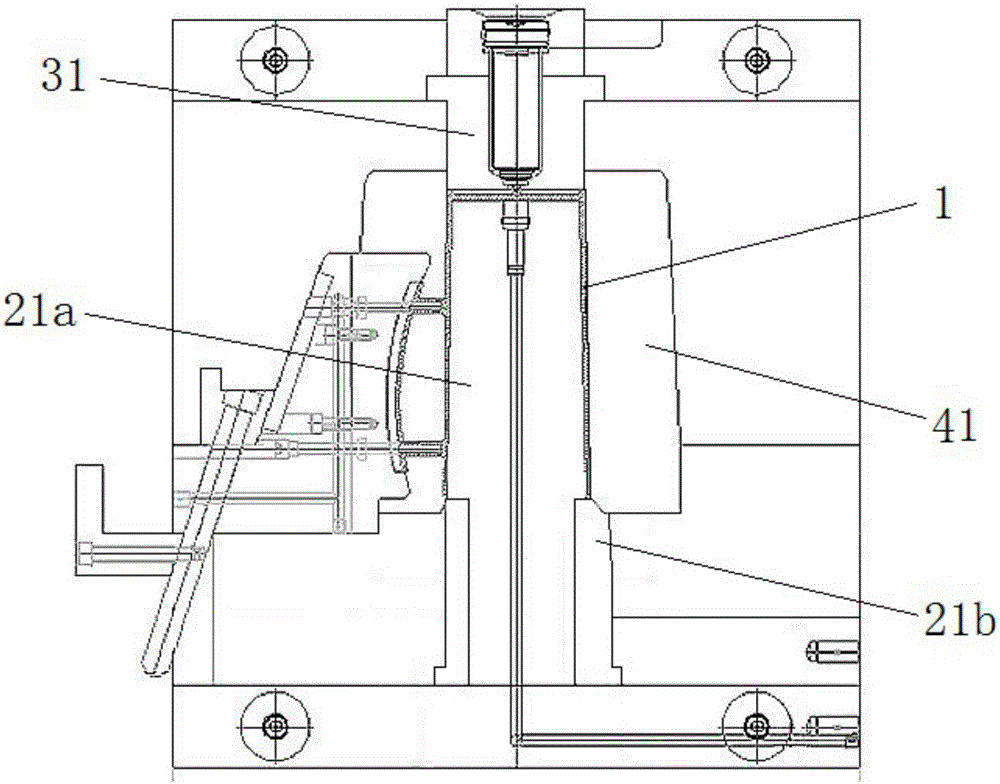

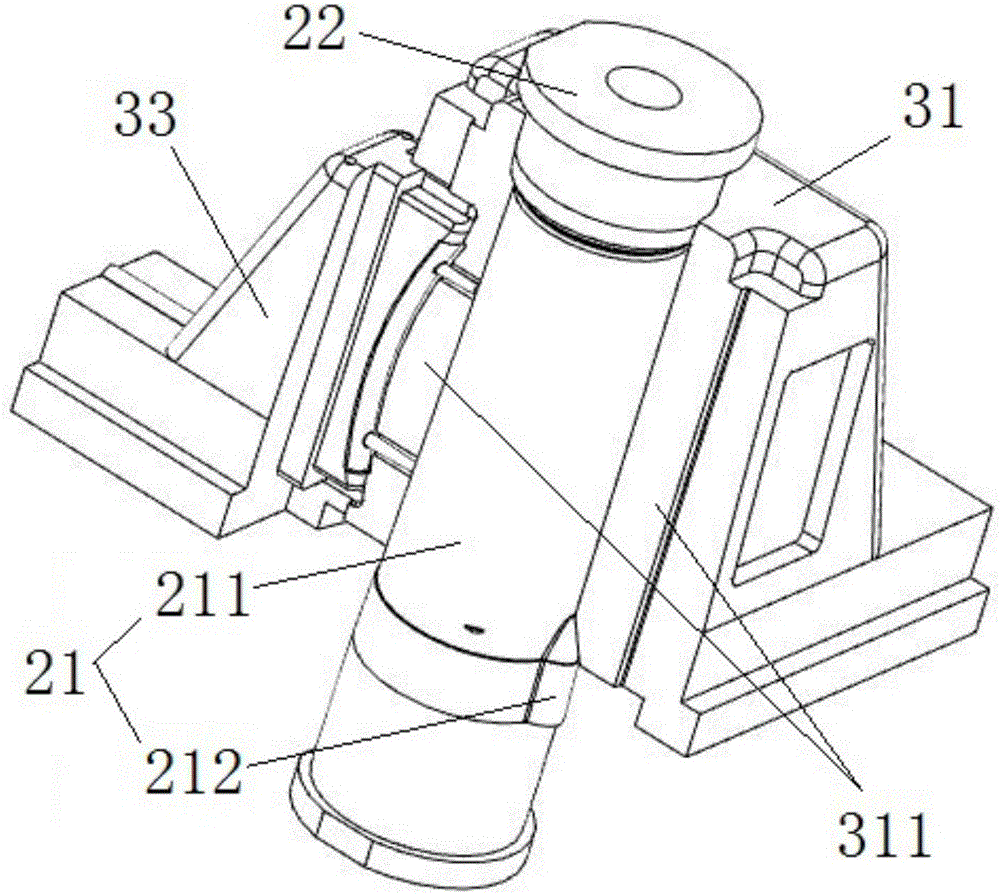

[0038] Such as figure 1 , Figure 3 to Figure 5 Shown, a kind of water bottle forming die of the present invention, comprises male mold insert 21, female mold insert 22 and some sliders that are assembled around male mold insert 21 and female mold insert 22 up and down, male mold insert The piece 21 includes a body 211 in the shape of a truncated cone. The body 211 has a thin end (not marked) close to the female die insert 22 and a thick end (not marked) away from the female die insert 22. The side of the thick end of the body 211 is integrally formed. A spout molded body 212 is arranged. During work, the male mold insert 21, the female mold insert 22 and each slide block are assembled to form the cavity of the kettle 1. Among them, the kettle body 11 of the kettle 1 is formed by the body 211 of the male mold insert 21. Because the spout molding body 212 and the body 211 are integrally formed, the kettle body 11 and the spout 12 of the kettle 1 can be seamlessly connected. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com