Positioning device capable of positioning multiple electronic components at same time and operation equipment adopting same positioning device

A technology of electronic components and positioning devices, which is applied in the directions of measuring devices, measuring device casings, and parts of electrical measuring instruments, etc., can solve problems such as deviation errors, inability to perform operations effectively, and reduce production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to make your examiner further understand the present invention, hereby give a preferred embodiment and cooperate with the drawings, as follows in detail:

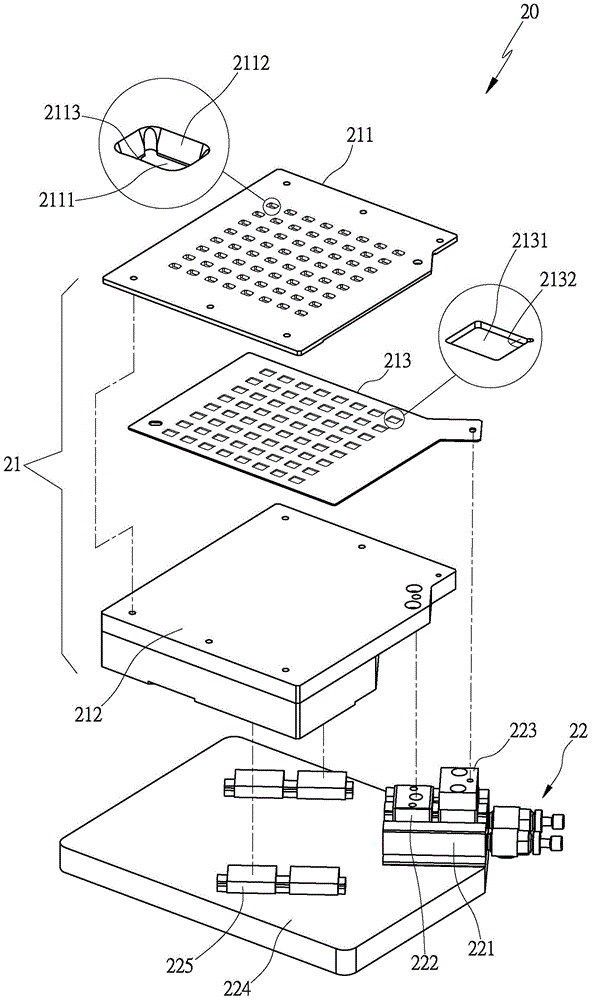

[0059] see image 3 , Figure 4 The positioning device 20 of the present invention includes a positioning mechanism 21 and a driving mechanism 22. The positioning mechanism 21 is provided with a plurality of grippers, and the grippers are provided with a plurality of abutting parts that can be positioned against a plurality of electronic components. Further, The actuation mode of the positioning mechanism 21 can be divided into a single-action pushing method and a double-action pushing method. When the positioning mechanism 21 adopts a single-action pushing method, it can be configured with a fixed clamp and a movable clamp. The movable clamp is opposite to the The displacement of the fixed clamping device enables the fixed clamping device and the movable clamping device to clamp and position multiple elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com