Friction corrosion fatigue test device and friction corrosion fatigue test method of heavy-load scraper plate conveyor circular chain

A scraper conveyor, fatigue test technology, applied in the mining industry, can solve problems such as circular link chain breakage, circular link chain friction and corrosion fatigue, etc., to achieve the effect of convenient operation and intuitive measurement results

Active Publication Date: 2017-01-04

CHINA UNIV OF MINING & TECH

View PDF6 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, the friction and corrosion fatigue phenomenon occurs in the circular chain of th

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

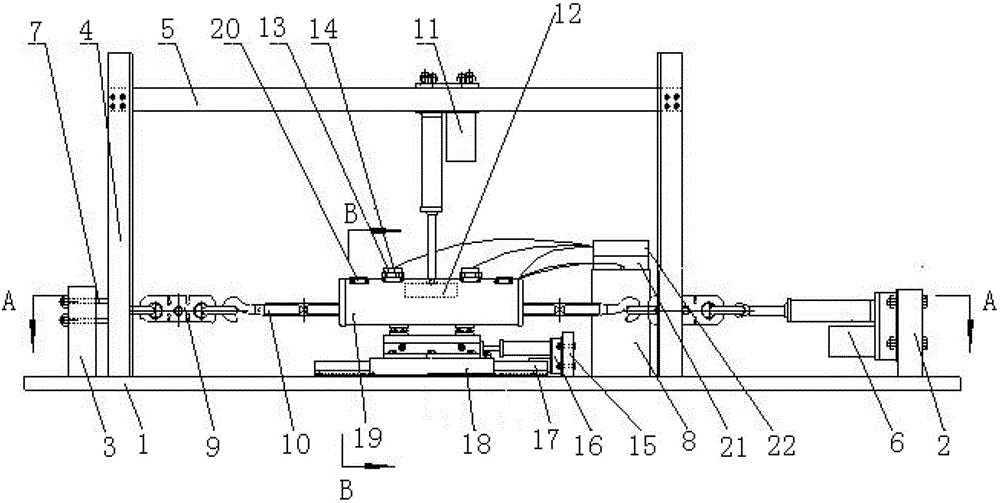

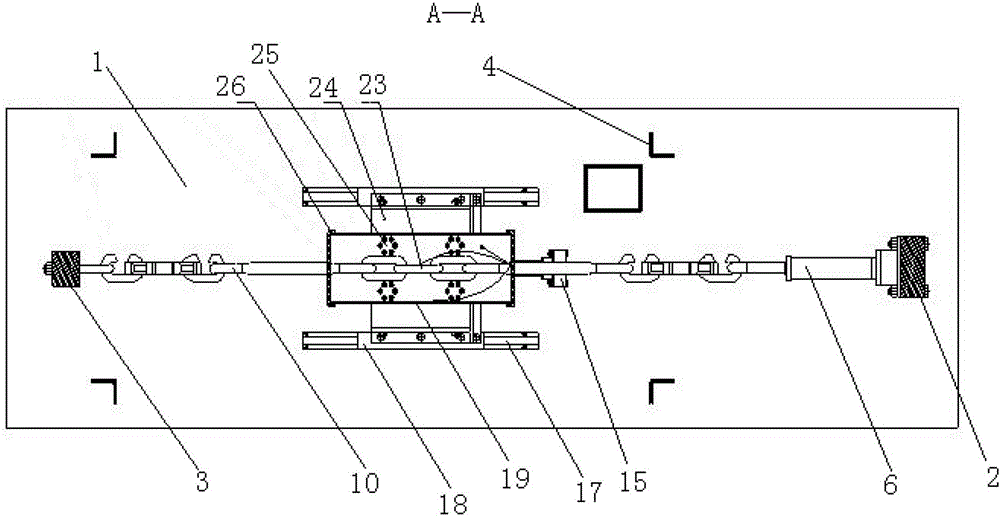

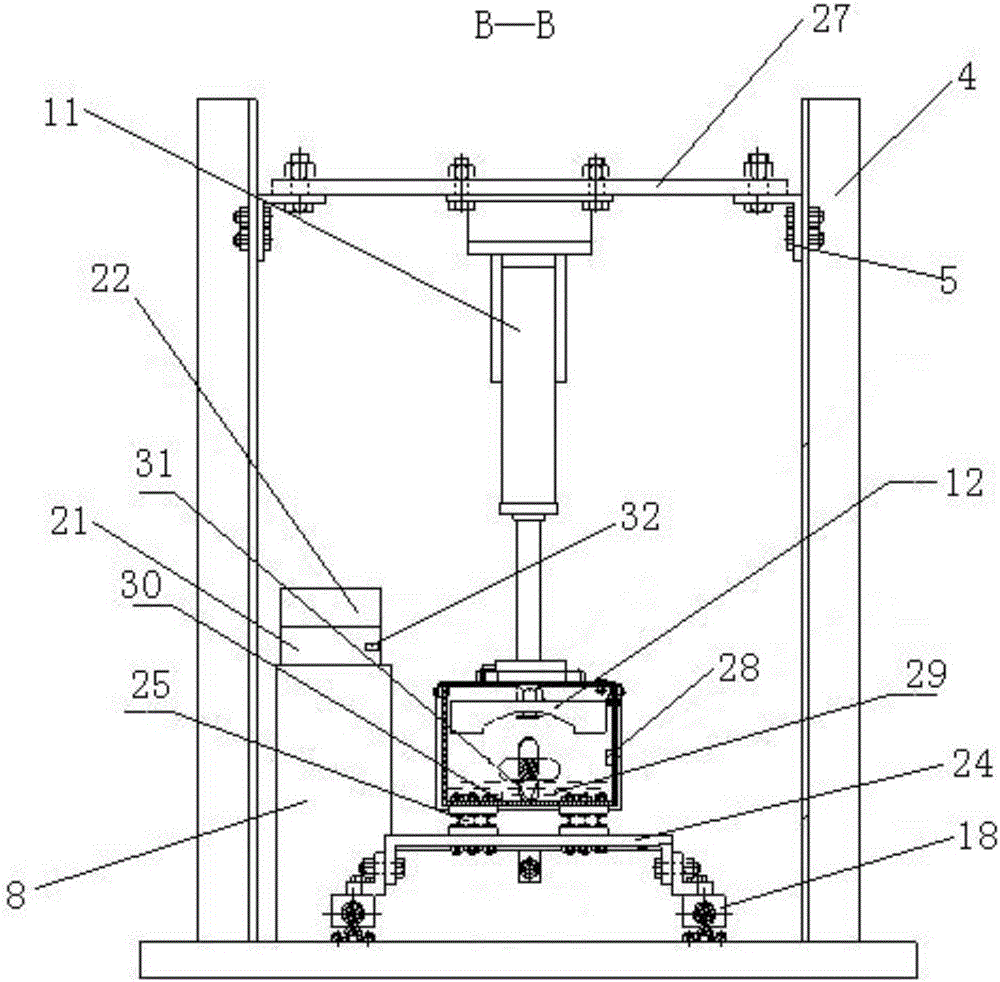

The invention discloses a friction corrosion fatigue test device and a friction corrosion fatigue test method of a heavy-load scraper plate conveyor circular chain. The friction corrosion fatigue test device comprises the following modules of a loading simulating system which applies a dynamic tension and an impact load on the circular chain through an electric cylinder and an impact plate; a heating simulating system which heats the inner part of a middle trough simulating box through a fan and a PCT electric heater; a friction simulating system which drives the middle trough simulating box through the electric cylinder for applying a friction force on the circular chain; a corrosion simulating system which is realized through adding corrosion media into the middle trough simulating box; and a monitoring system which realizes monitoring on the dynamic tension, the friction force, the impact load, the temperature, the corrosion wearing rate and the fatigue life of the circular chain through a plate ring tension sensor, a three-dimensional force sensor, a temperature sensor, a temperature control box, an auxiliary electrode, a working electrode, a reference electrode and an electrochemical work station. The friction corrosion fatigue test device and the friction corrosion fatigue test method have advantages of convenient operation, comprehensive and reliable testing result, and important guiding meaning in safe and reliable operation of the heavy-load scraper plate conveyor circular chain in a complicated operation environment.

Description

technical field [0001] The invention relates to the field of mining technology, in particular to a friction and corrosion fatigue test device and method for a circular chain of a heavy-duty scraper conveyor. Background technique [0002] Fully mechanized mining technology is the most advanced underground mining technology today, and the scraper conveyor is one of the key fully mechanized mining equipment. It not only plays the role of coal transportation, but also the running track of the coal shearer. With the continuous development of fully mechanized mining technology, as well as the large-scale and deep mines, the scraper conveyor continues to develop in the direction of high power, long distance and high chain speed, that is, the heavy-duty scraper conveyor. Once the heavy-duty scraper conveyor fails due to failure, it will lead to the shutdown of the coal mining face, which will lead to major economic losses in large coal mines. [0003] As an important part of the tr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01M13/02

CPCG01M13/023G01M13/027

Inventor 张俊王大刚朱真才张德坤

Owner CHINA UNIV OF MINING & TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com