A connection structure and a connection system between a column and a closed beam

A technology for connecting structures and beams, which is applied to building components, building structures, walls, etc., can solve the problems of weakening mechanical properties such as beam resistance to torsion, etc., and achieve simple and easy structure, safe structure stress, and convenient processing and loading and unloading Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

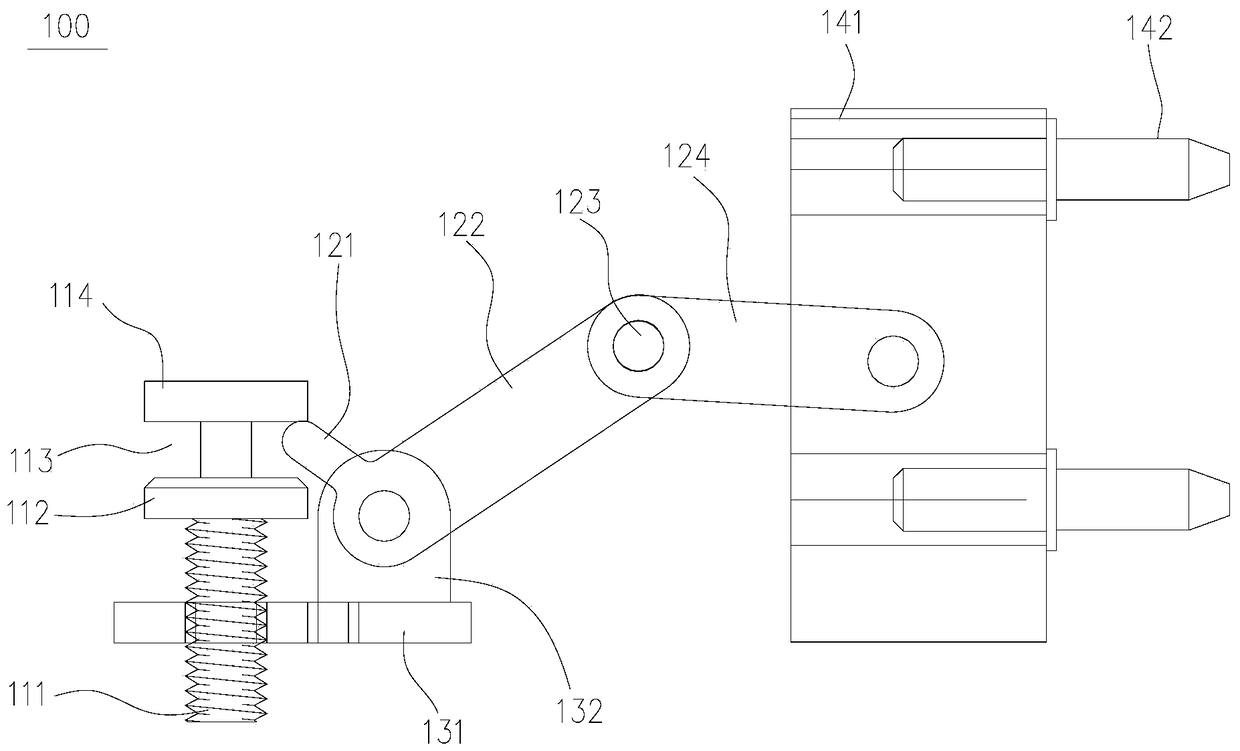

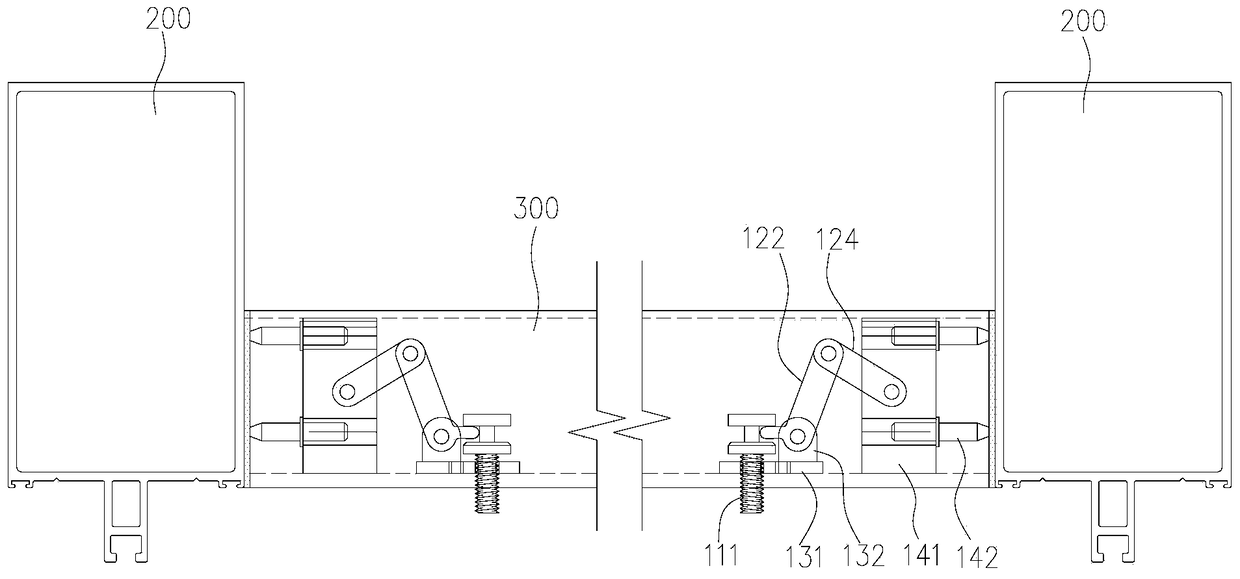

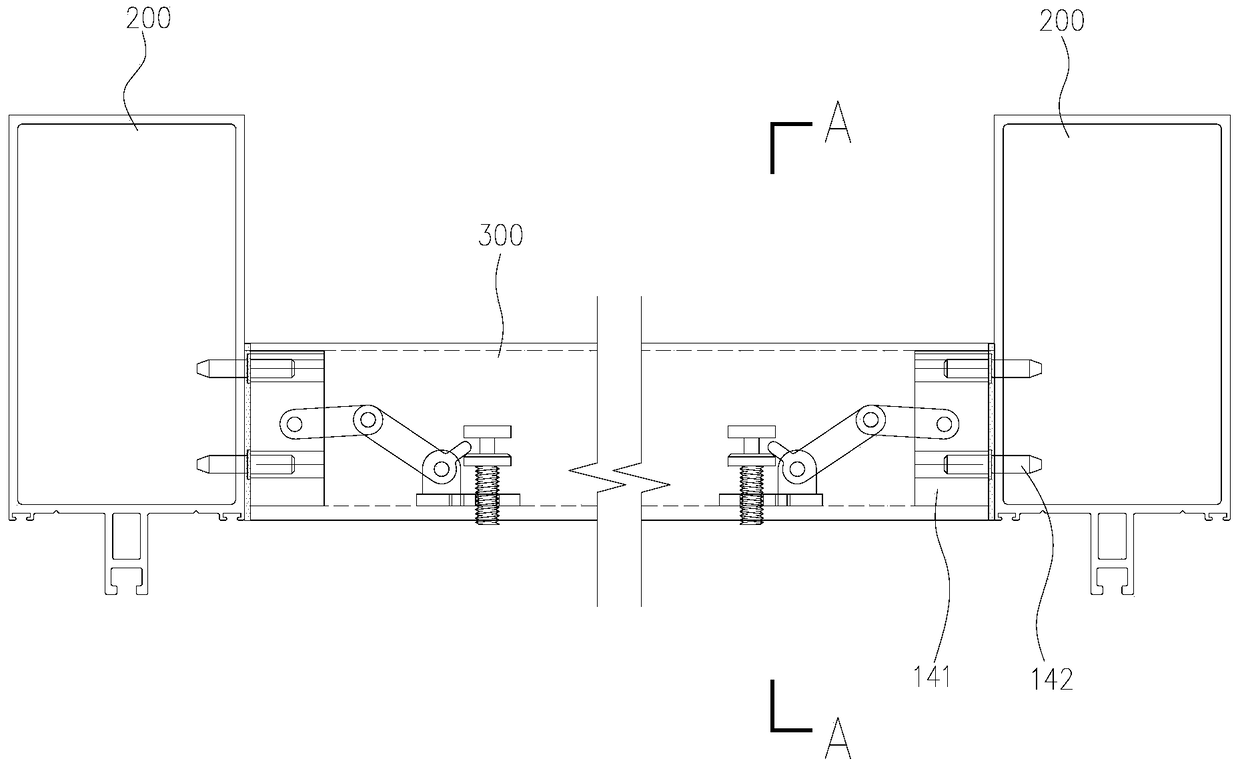

[0017] refer to Figure 1-4 , the present embodiment provides a connection structure 100 for connecting a frame-type closed beam to a column, and a system for connecting a column to a closed beam using the connection structure 100 .

[0018] The connection structure 100 includes a control screw 111, a base 131, a linkage mechanism, a fastening ferrule 141 and a fastening pin 142, such as figure 1 shown. A connection block 132 for connecting with the linkage mechanism is provided on the base 131 , and a screw hole for the control screw 111 to pass through is provided beside the connection block 132 . A screw cap 114 is disposed on the control screw 111 , and a ring of protruding edge 112 is disposed under the screw cap 114 . The locking position 113 is formed by the screw cap 114 , the protruding edge 112 below the screw cap 114 , and the distance between them. The control screw 111 passes through the screw hole on the base 131 , and the control screw 111 can move up and dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com