A large component translation device and method

A technology of large-scale components and translation devices, which is applied in the direction of transportation and packaging, movable tracks, conveyors, etc., can solve the problems of reducing the number of translation times, the translation device cannot be too heavy, and the installation and translation of large components is difficult, so as to improve the moving speed, The effect of wide application range and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, the present invention is illustrated

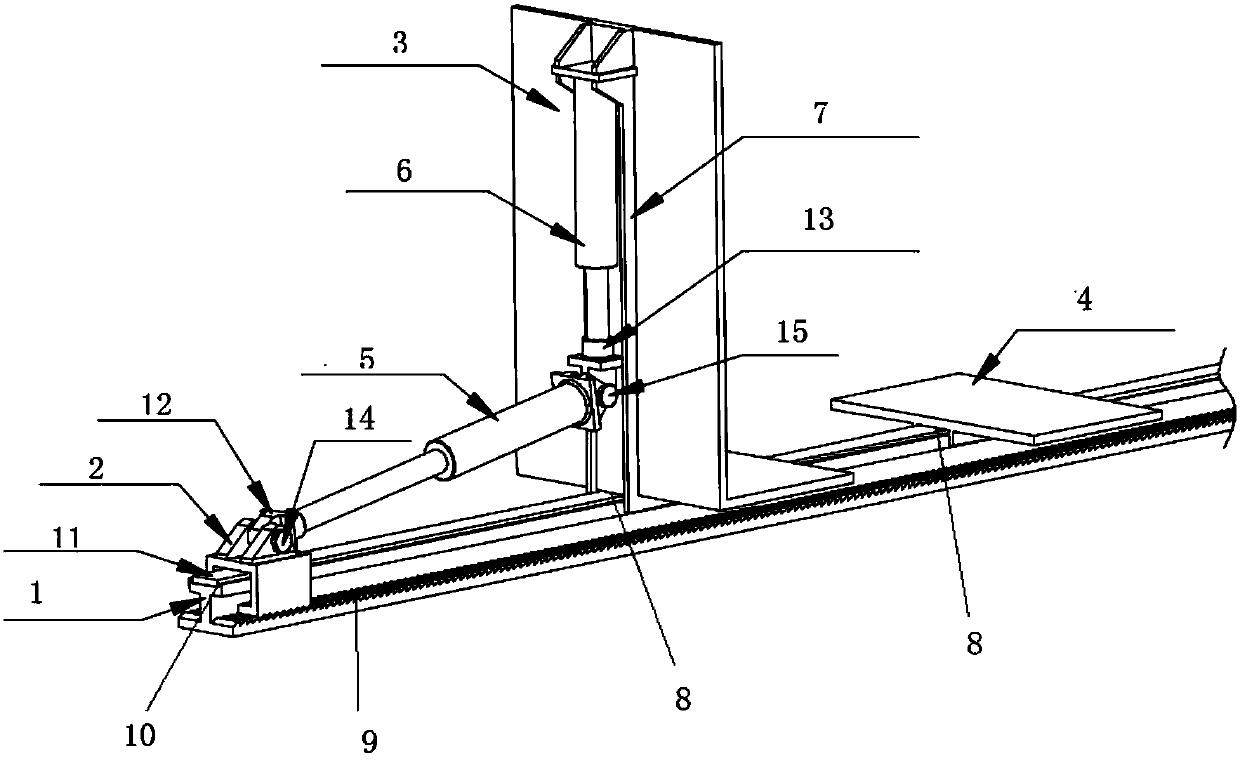

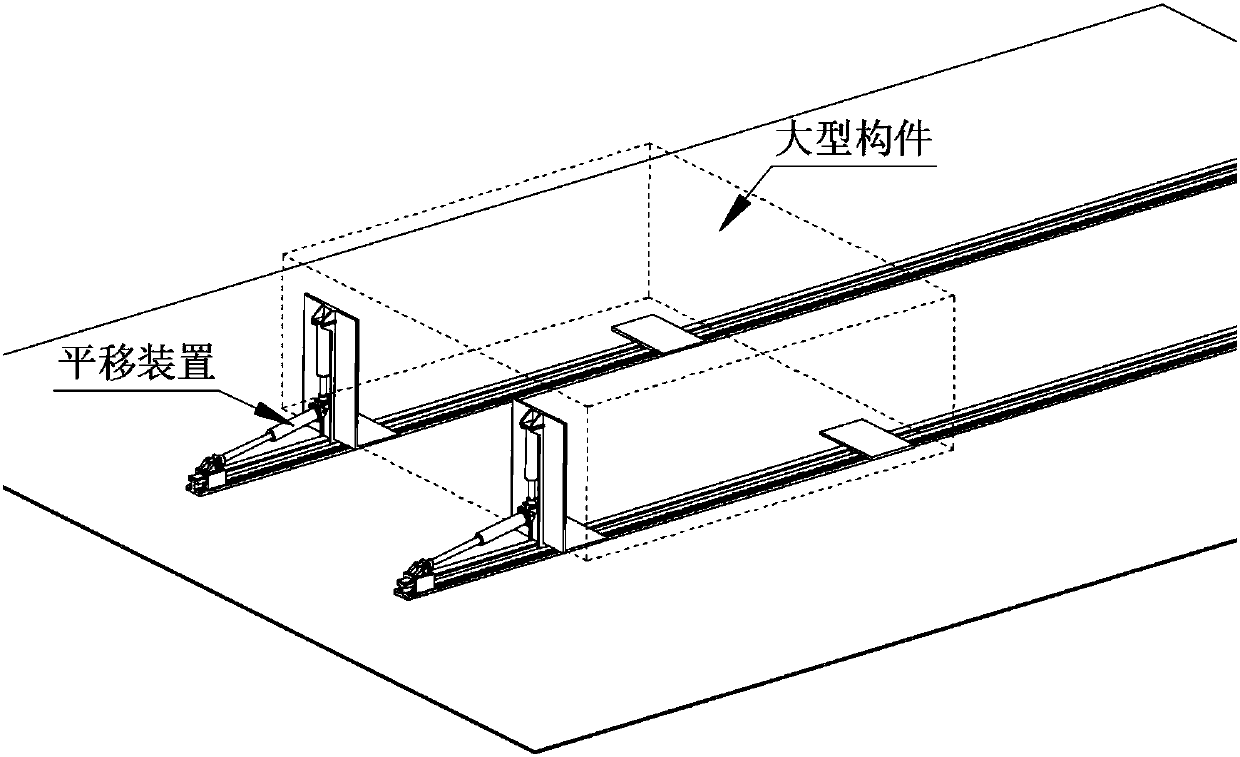

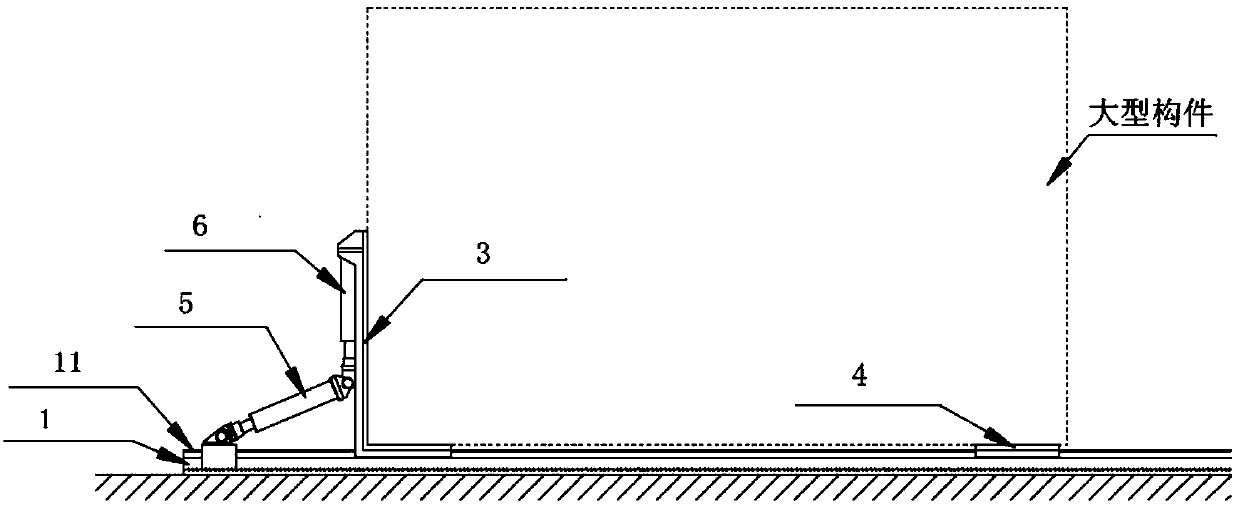

[0030] The present invention is a large component translation device and method. The device consists of a guide rail support 1, a sliding gasket 11, a self-locking fixture 2, a rotating hinge support 12, a first jack 5, a sliding hinge support 13, The limit groove 8, the second jack 6, the first sliding support 3 and the second sliding support 4 are composed of ( figure 1 ). The self-locking fixture 2 in the device is nested on the guide rail support 1, and a continuous one-way tooth 9 is arranged between the two. The top of the guide rail support 1 is provided with a sliding slot 10 for placing the sliding gasket 11 to limit the displacement between the sliding gasket 11 and the guide rail support 1 . The first jack 5 is connected with the self-locking fixture 2 and the second jack 6 respectively, and the self-locking fixture 2 is provided with a rotary hinge support 12, and the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com