A kind of continuous anode device for intelligent electrolyzer and using method thereof

An anode device and electrolytic cell technology, which is applied in the field of metallurgy, can solve the problems of difficult replacement of prebaked anode size, large amount of residual electrode processing, and high quality requirements of special bonding paste, so as to achieve online continuous installation, reduce electromagnetic field fluctuations, and improve The effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A continuous anode device for an intelligent electrolyzer, comprising a continuous anode carbon block 5, an anode carbon block positioning and pushing system, a continuous anode carbon block crawler displacement system, a sliding power supply system and an intelligent control system;

[0060] The continuous anode carbon block is composed of multiple anode carbon block units connected in series;

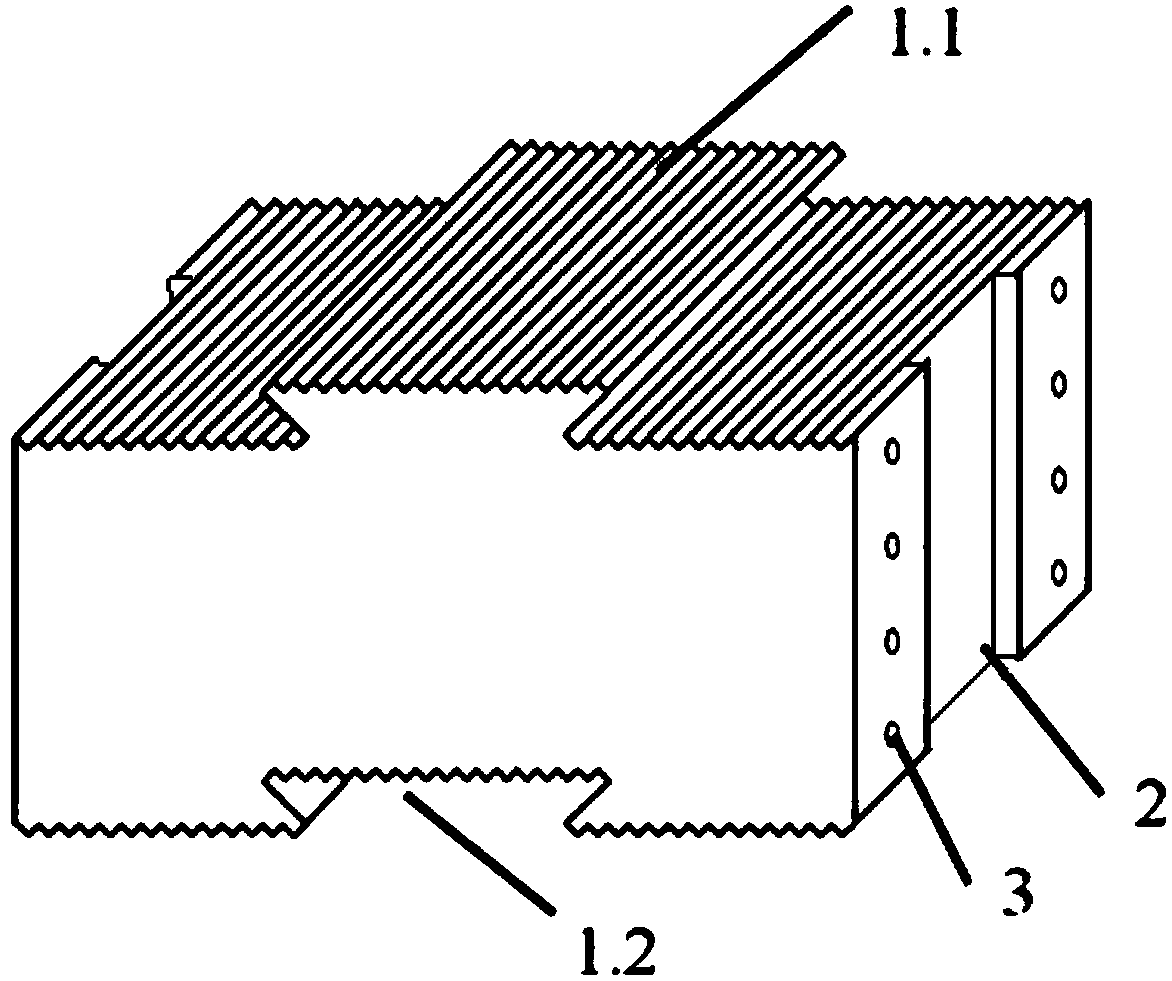

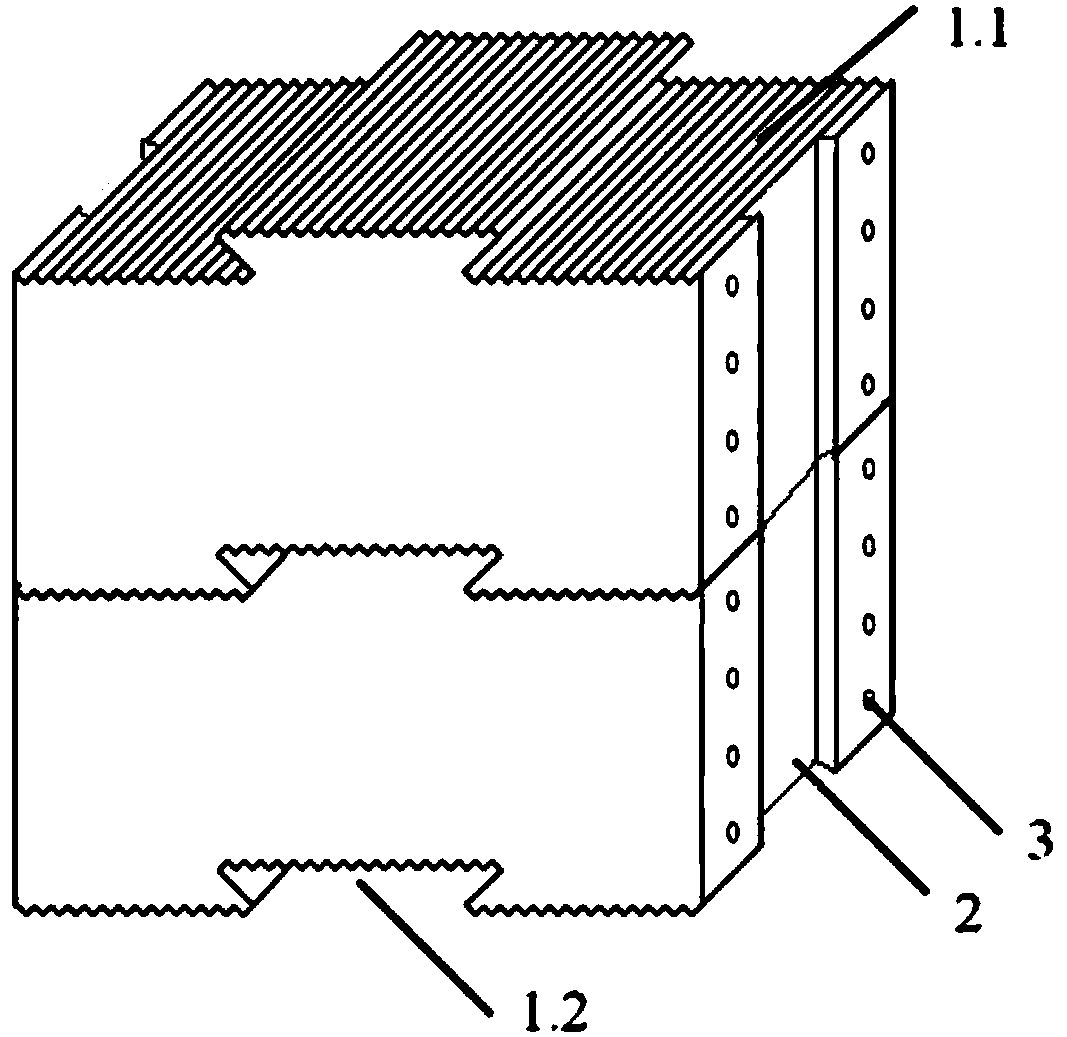

[0061] The continuous anode carbon block has a cuboid or cube structure, with a clamping block 1.1 on the upper surface and a clamping groove 1.2 on the lower surface, both of which are sawtooth corrugated surfaces; Road 2, on both sides of the slideway is a planar fastening area 3 with a row of fastening holes.

[0062] The anode carbon block positioning push system includes a support, a mobile pusher 8 and a limit baffle 9; the support is a horizontal support 6 and a vertical support 7, and the vertical support 7 and the limit baffle 9 are arranged on the raw surface of the c...

Embodiment 2

[0082] A continuous anode device for an intelligent electrolyzer, comprising a continuous anode carbon block 5, an anode carbon block positioning and pushing system, a continuous anode carbon block crawler displacement system, a sliding power supply system and an intelligent control system;

[0083] The continuous anode carbon block is composed of multiple anode carbon block units connected in series;

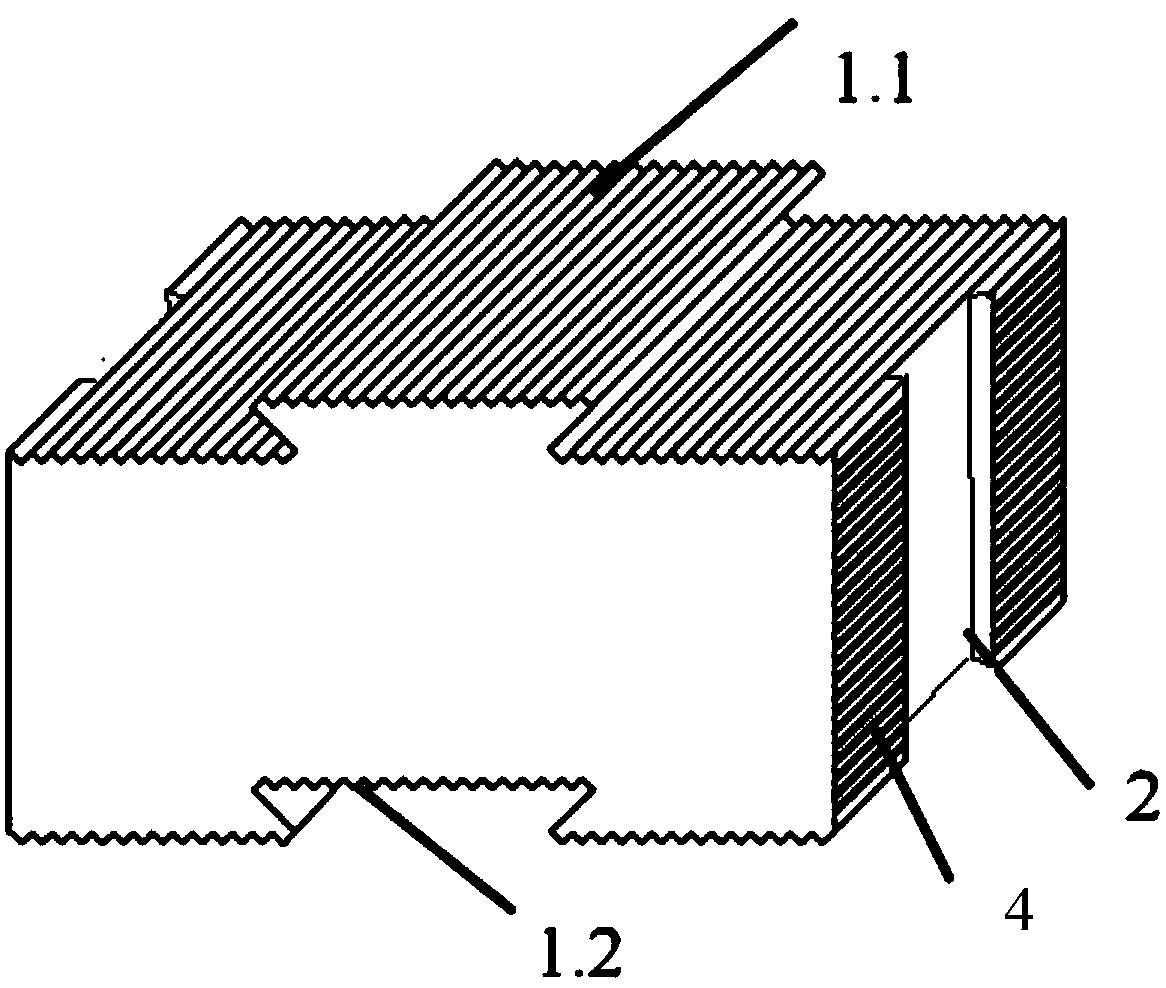

[0084] The continuous anode carbon block has a cuboid or cube structure, with a clamping block 1.1 on the upper surface and a clamping groove 1.2 on the lower surface, both of which are sawtooth corrugated surfaces; Road 2, on both sides of the slideway is a fixed connection area 4 with a row of sawtooth corrugated surfaces running through.

[0085] The anode carbon block positioning push system includes a support, a mobile pusher 8 and a limit baffle 9; the support is a horizontal support 6 and a vertical support 7, and the vertical support 7 and the limit baffle 9 are arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com