Lifting frame adopting independent framework foundation and operating method

A technology with independent foundation and operation method, applied in the direction of load hanging components, transportation and packaging, etc., can solve problems such as inability to hoist, limited bearing capacity of structural members, and inability to set rigid bases, etc., to achieve convenient operation, reduce impact, and good promotion value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to set forth the present invention more clearly, the invention will be further described below through specific examples.

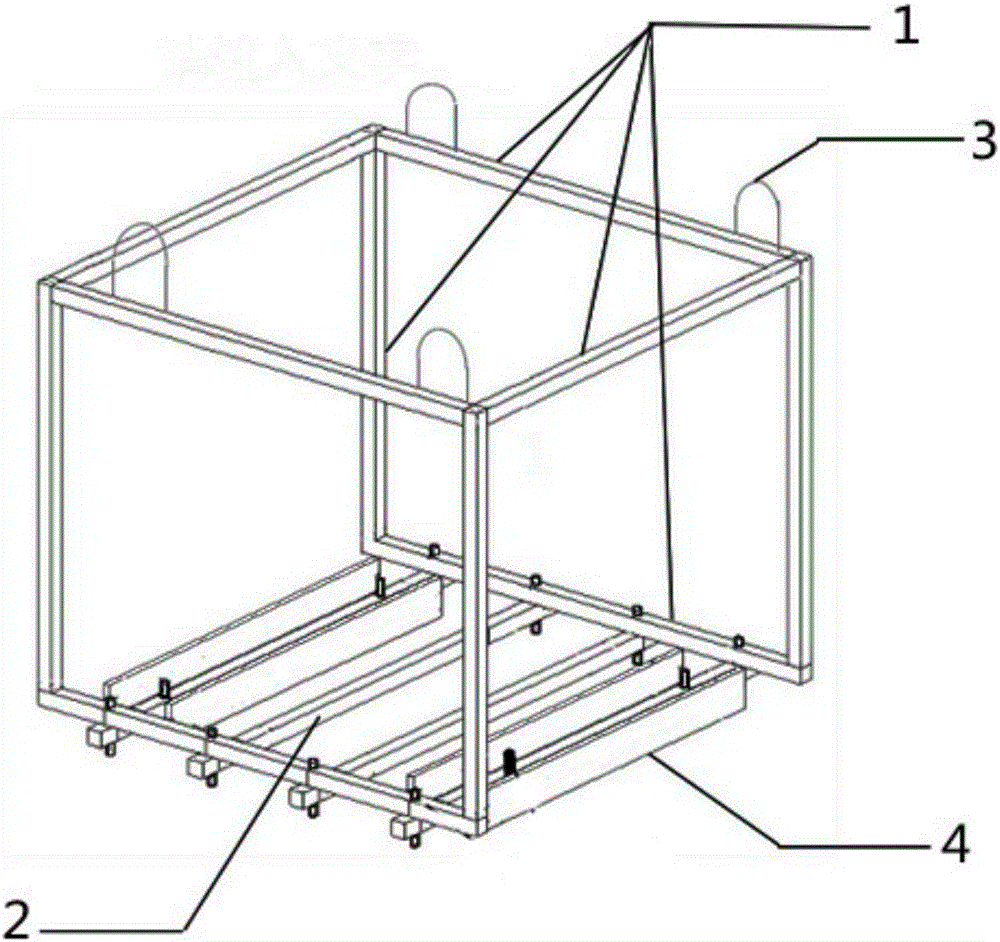

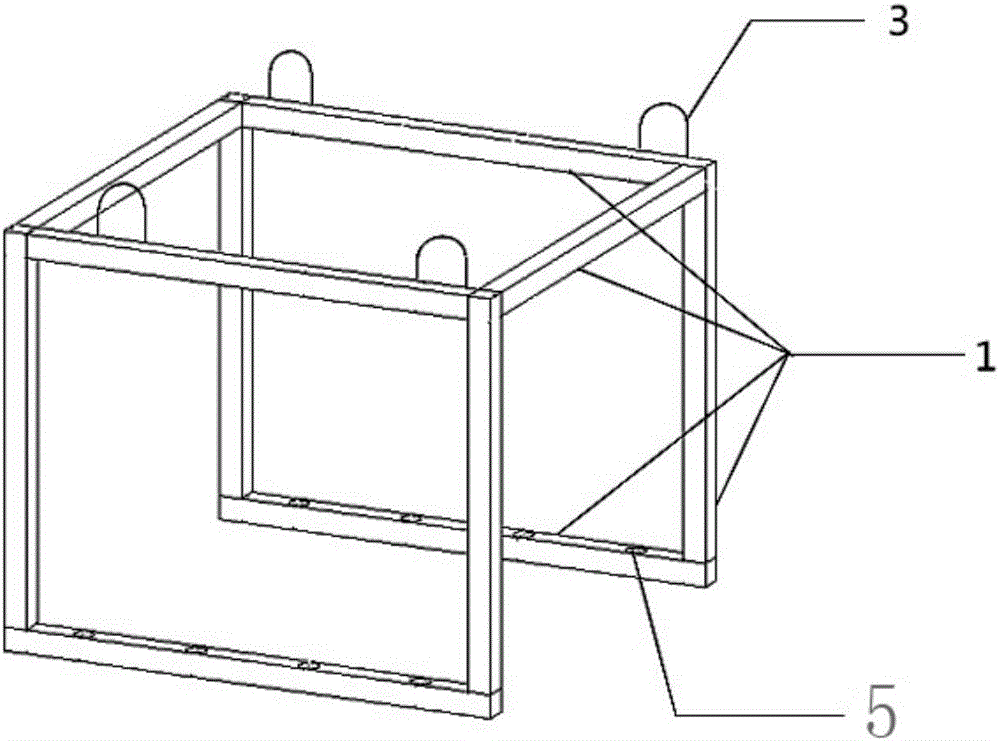

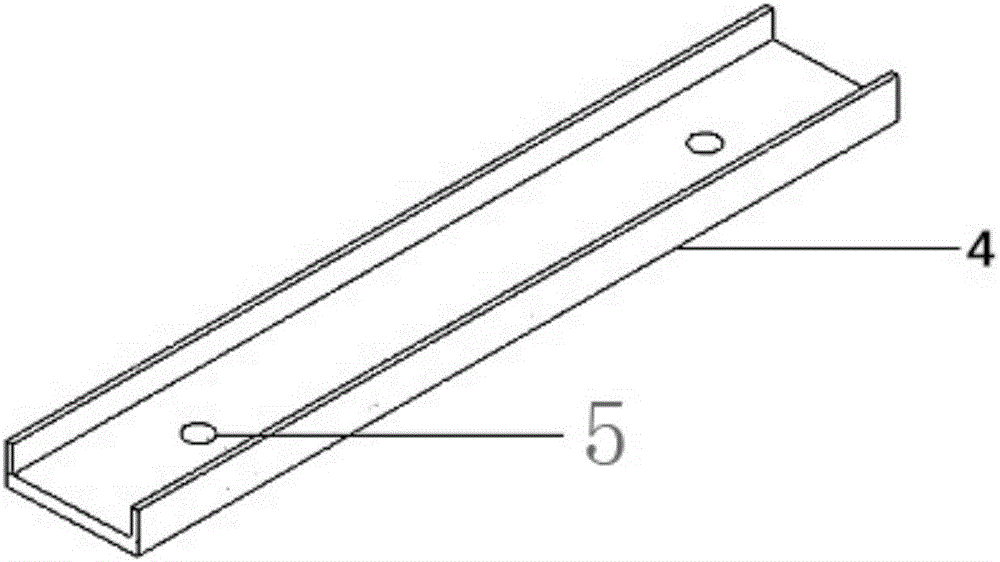

[0025] Such as Figure 1 to Figure 5 As shown, a frame independent foundation hanger includes a steel frame 1, a bottom square steel 2 and a channel steel 4.

[0026] The top of the steel frame 1 is a rectangular frame welded by four square steels. The four apexes of the rectangular frame are respectively welded with four vertically downward square steels perpendicular to the plane of the rectangular frame. The bottom of the steel frame 1 is two The root parallel square steels are welded between the bottom ends of a pair of square steels perpendicular to the plane of the rectangular frame. The two square steels at the bottom of the steel frame 1 are equidistantly provided with several bolt holes; the bottom square steel 2 is vertically fixed between the two square steels at the bottom of the steel frame 1 by bolts; Bolts are installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com